YJJY-3A PU Foam Polyurethane Spray Coating Machine

1.AirTAC’s original profile cylinder is used as the power for boosting to enhance the working stability of the equipment

2.It has the characteristics of low failure rate, simple operation, quick spraying, convenient movement and high cost performance.

3.The equipment adopts upgraded T5 feeding pump and 380V heating system, which solves the disadvantages of unsuitable construction when the viscosity of raw materials is high or the ambient temperature is low.

4.The main engine adopts the pure pneumatic reversing mode, the continuous work is stable and is equipped with a reset button

5.Rear-mounted dust-proof decorative cover + side-opening decorative door effectively prevents dust, blanking and facilitates electrical inspection

6.The spray gun has the advantages of small size, light weight, high wear resistance mixing chamber, low failure rate, etc.

7.The whole machine is an upgraded version of the 3rd generation product, the design is more user-friendly, and the pressure of the spraying distance of 90 meters is not affected.

8.The heating system adopts the self-tuning PiD temperature control system, which automatically adapts to the temperature difference setting, and cooperates with the perfect temperature measurement and over-temperature system to ensure the precise control of material temp犀利士

erature.

9.Proportional pump barrel and lifting piston are made of high wear-resistant and high-strength materials, which can reduce the wear of seals and prolong the service life.

| Medium Raw Material |

polyurathane |

|

Maximum Fluid Temperature |

90°C |

|

Maximum Output |

11kg/min |

|

Maximum Working Pressure |

10Mpa |

|

Heating Power |

17kw |

|

Hose Maximum Length |

90m |

|

Power Parameters |

380V-40A |

|

Drive Method. |

pneumatic |

|

Volume Parameter |

690*700*1290 |

|

Package Dimensions. |

760* 860*1220 |

|

Net Weight |

120kg |

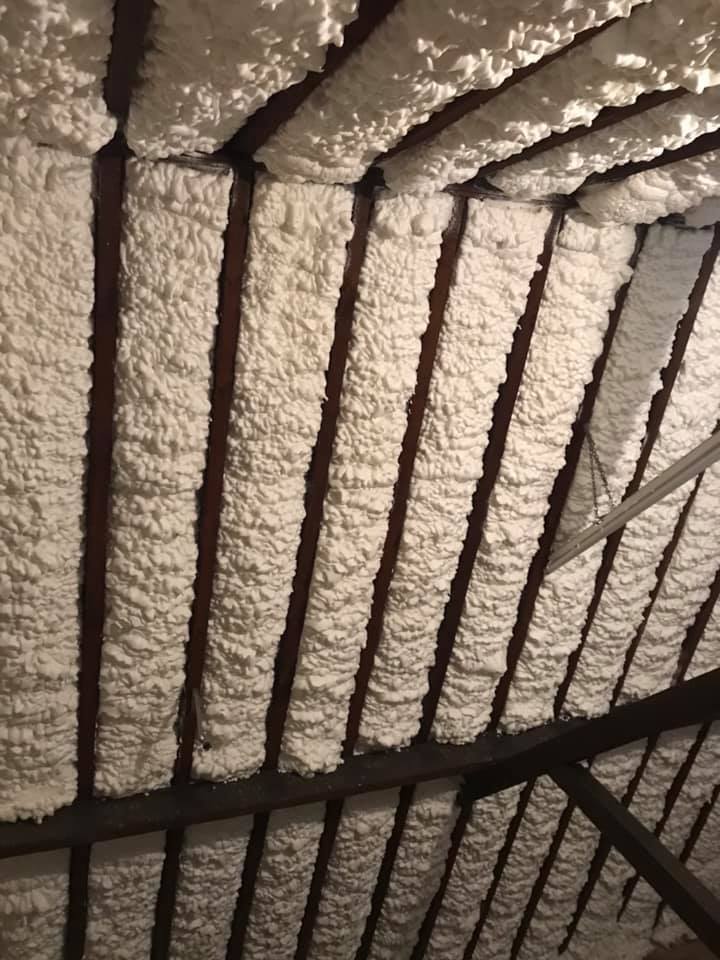

It is widely used in polyurethane exterior wall, roof, cold storage, tank body, pipeline thermal insulation spraying and pouring, new energy vehicle thermal insulation and noise reduction, ship hull composite, bridge column thermal insulation and anti-collision, etc.