High Pressure Polyurethane Foam Injection Machine

Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, polyol and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

Product Features of High Pressure PU Machine:

1. Material injection mixing head can freely move forward and backward, left and right, up and down;

2. Pressure needle valves of black and white materials locked after balanced to avoid pressure difference;

3. Magnetic coupler adopts high-tech permanent magnet control, no leakage and temperature rising;

4. Automatic gun cleaning after injection;

5. Material injecting procedure provides 100 work stations, weight can be set directly to meet the production of multi-products;

6. Mixing head adopts double proximity switch control, which can realize precise material injection;

7. Automatic switch from frequency converter soft start to high and low frequency, low-carbon , energy saving, environmental protection, greatly reduce the energy consumption;

8. Full digital, modular integration control all process, accurate, safe, intuitive, intelligent and humanization.

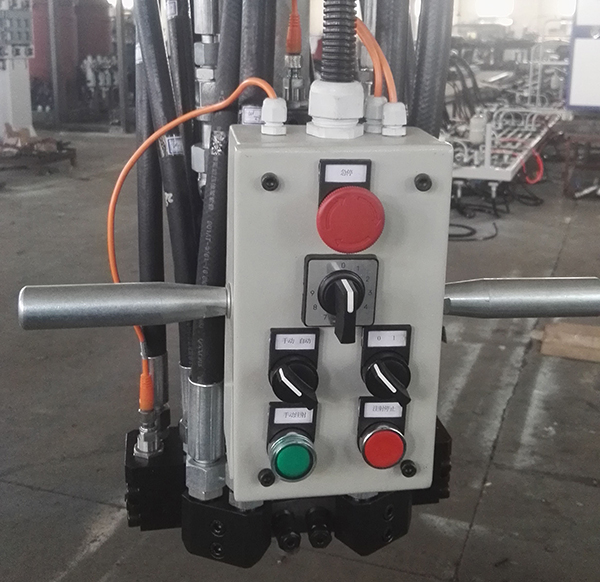

Mixing head

Adopt L type automatic self-cleaning mixing head, needle type nozzle adjustable, V type jet orifice, High-pressure collisional mixing principle ensure mixing effectual. Mixing head operation box installed with: high/low pressure switch, injection button, Station feeding selection switch, emerge stop button and etc.

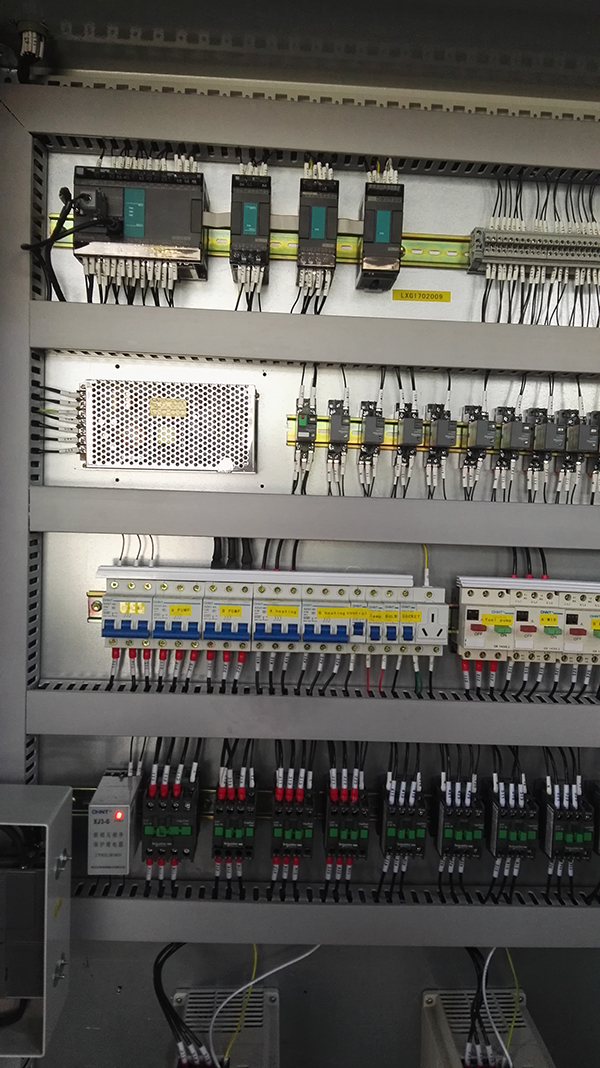

Electric control system

Adopting Siemens programmable controller and whole foaming machine automatic controlled, make metering unit, hydraulic unit, temp control system, tank agitator, mixing head injection coordinate the work according to the procedures, ensure process efficiency and reliable.

Material tank unit

250L Polyol tank+250L Isocyanate tank, thermostatic control by two layer wall with insulation layer, a set of high accuracy metering device installed on the frame, 1 set of German imported high-pressure flow meter, used to measure and regulate the flow of raw materials.

|

No. |

Item |

Technical parameter |

|

1 |

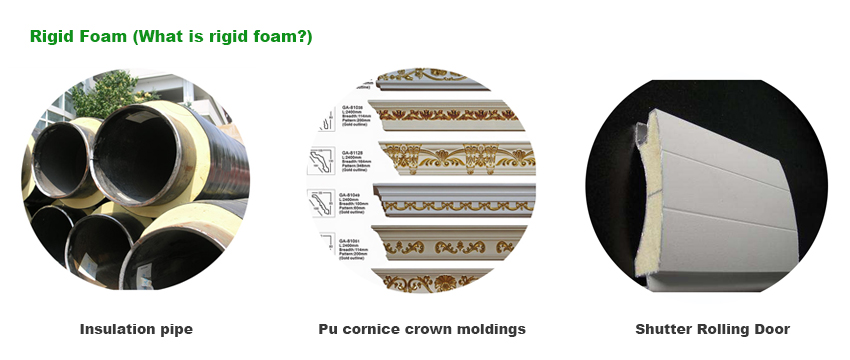

Foam application |

Flexible Foam/Rigid Foam |

|

2 |

Raw material viscosity(22℃) |

POLY ~2500MPas ISO ~1000MPas |

|

3 |

Injection pressure |

10-20Mpa(adjustable) |

|

4 |

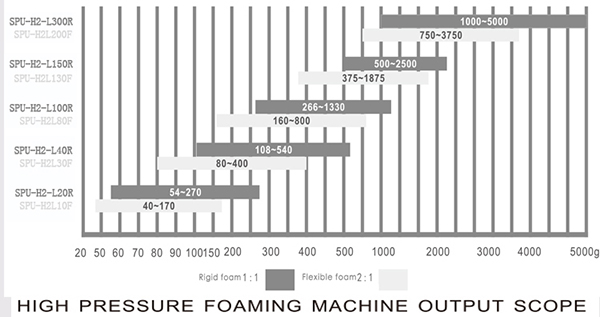

Output (mixing ratio 1:1) |

40-5000g/s |

|

5 |

Mixing ratio range |

1:3~3:1(adjustable) |

|

6 |

Injection time |

0.5~99.99S(correct to 0.01S) |

|

7 |

Material temperature controlling error |

±2℃ |

|

8 |

Repeat injection accuracy |

±1% |

|

9 |

Mixing head |

Four oil house,double oil cylinder |

|

10 |

Hydraulic system |

Output: 10L/min System pressure 10~20MPa |

|

11 |

Tank volume |

500L |

|

15 |

Temperature control system |

Heat: 2×9Kw |

|

16 |

Input power |

Three-phase five-wire 380V |