Polyurethane Wood Ketsiso e Rigid Foam Photo Frame Molding Machine

Mochini o phoroselang oa polyurethane, o na le ts'ebetso ea moruo, e bonolo le tlhokomelo, joalo-joalo, e ka etsoa ho latela kopo ea moreki e fapaneng e tsoang mochining.

Senapolyurethanemochini o fokang foam o sebelisa lisebelisoa tse peli tse tala, polyurethane le Isocyanate.Mofuta ona oa mochini oa foam oa PU o ka sebelisoa liindastering tse fapaneng, joalo ka litlhoko tsa letsatsi le letsatsi, koloi.mokgabiso, lisebelisoa tsa bongaka, indasteri ea lipapali, lieta tsa letlalo, indasteri ea ho paka, indasteri ea thepa ea ka tlung, indasteri ea sesole.

Likarolo tsa Sehlahisoa tsa Mochini oa High Pressure PU:

1.Ho amohela tanka ea polokelo ea lera tse tharo, liner tsa tšepe e sa hloekang, mocheso oa mofuta oa sandwich, ka ntle e phuthetsoe ka lera la ho kenya letsoho, mocheso o fetohang, o bolokehileng le o bolokang matla;

2.Ho eketsa sistimi ea tlhahlobo ea lisebelisoa, e ka fetoloang ka bolokolohi ntle le ho ama tlhahiso e tloaelehileng, e boloka nako le thepa;

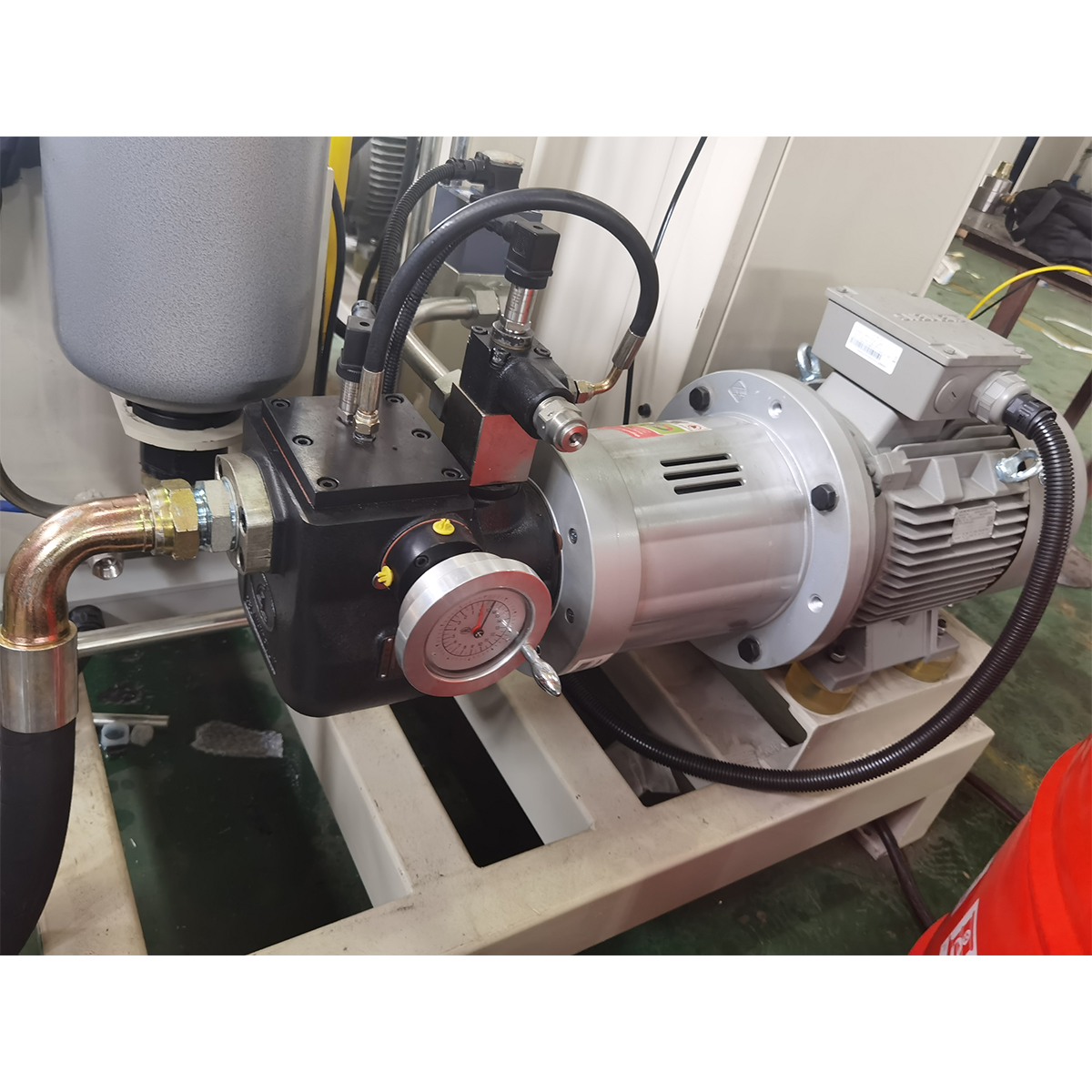

3.Low lebelo phahameng ho nepahala meteringpump, karo-karolelano e nepahetseng, phoso e sa reroang ka hare ho ± 0.5%;

4.Sekhahla sa phallo ea thepa le khatello e fetotsoeng ke mochine oa motlakase o nang le taolo ea maqhubu a feto-fetohang, ho nepahala ho phahameng, ho lokisoa ha lijo tse bonolo le tse potlakileng;

Sesebelisoa se tsoakiloeng sa 5.High-performance, ka nepo se hlahisoang ke thepa ea synchronous, esita le motsoako.Sebopeho se secha sa ho lutla, sebopeho sa potoloho ea metsi a batang se boloketsoe ho netefatsa hore ha ho na thibelo nakong ea nako e telele;

6.Adopting PLC le touch screen man-machine interface ho laola ente, ho hloekisa ka mokhoa o itekanetseng le ho phalla ha moea, ts'ebetso e tsitsitseng, ts'ebetso e phahameng, ho khetholla ka ho toba, ho hlahloba le ho alamo boemo bo sa tloaelehang, ho bontša lintho tse sa tloaelehang.

Sehlopha sa sesebelisoa sa ho laola khatello e phahameng, se sebelisetsoang ho fetola le ho laola khatello ea ho sebetsa le ho beha khatello pakeng tsa 6MPa ho ea ho 22MPa, ha khatello e holim'a marang-rang, lisebelisoa tse sa sebetseng hantle le ho bontša molaetsa oa phoso oa khatello e phahameng / e tlaase.

Filter e sebelisoa bakeng sa filthara ea lintho tse bonahalang, e sebelisa mochini oa ho itlhoekisa o nepahetseng, kahoo ho qoba ho qhaqhoa khafetsa, ho boloka nako le ho sebetsa hantle.

Hlooho ea ho kopanya e amohela hlooho ea ho itlhoekisa ea mofuta oa L, mofuta oa nale oa mofuta oa nozzle o ka fetolehang, V mofuta oa jet orifice, molao-motheo o kopanyang oa khatello e phahameng o netefatsa hore motsoako o sebetsa hantle.

Sistimi ea taolo ea motlakase e nka sebopeho sa komporo ea motho, e beha nako ea ente, nako ea teko le nako ea khatello joalo-joalo.

Chiller, E sebelisetsoa ho fana ka metsi a pholileng sebakeng se pholisang, matla a sehatsetsing 38700Kcal/h ;(likhetho)

| Che. | Ntho | Tekheniki parameter |

| 1 | Kopo ea foam | Mokhabiso Crown Moldings |

| 2 | Viscosity ea lintho tse tala(22℃) | POLY ~2500MPasISO ~1000MPas |

| 3 | Khatello ea ente | 10-20Mpa (e ka fetoloang) |

| 4 | Sephetho (motsoako oa karolelano 1:1) | 160–800g/s |

| 5 | Ho kopanya karo-karolelano | 1:5–5:1 (e ka feto-fetoha) |

| 6 | Nako ea ente | 0.5~99.99S(e nepahetseng ho isa ho 0.01S) |

| 7 | Phoso ea ho laola mocheso oa thepa | ±2℃ |

| 8 | Pheta ho nepahala ha ente | ±1% |

| 9 | Ho kopanya hlooho | Ntlo ea oli e mene, silindara ea oli e habeli |

| 10 | Sistimi ea Hydraulic | Tlhahiso: 10L/min Khatello ea tsamaiso 10~20MPa |

| 11 | Bophahamo ba tanka | 250L |

| 12 | Matla a kenyang | Mekhahlelo e meraro ea terata ea 380V |

1. E entsoe ka thepa ea polyurethane: e entsoeng ka ho lahla hlobo 'me e fapane le foreimi ea lehong.

2. E-ba le tšobotsi ea lehong: e ka chekoa, ea khokhotheloa le ho khaola liforeimi tsa seipone

3. Qetello ea mebala e fapaneng: joalo ka silevera, lenaka la tlou, e ntšo, lepa, ciliegia, molora, sootho, khauta ea khale kapa mebala e meng e fumaneha.

4. E-ba le moralo o mocha o kenyelletsang foreimi ea khale e majabajaba le foreimi ea setaele sa sejoale-joale.

5. Meralo e hlophisitsoeng, boholo le liphutheloana lia amoheloa.

6. E behiloe ka pente, seipone bakeng sa mokhabiso oa lebota kapa e etsoe e le foreimi ea lifoto bakeng sa litšoantšo tsa lelapa.

7. Tšebeliso e tšoarellang le ho boloka tikoloho: ho thibela metsi, ho thibela mongobo le ho thibela hlobo.

[2020] Polyurethane Foaming Machine Bakeng sa Thepa E etsisang Lejoe la Seipone la Lehong