Multi-component Cast Elastomer Polyurethane Machines (MDI/TDI) For PU Wire Guide Rollers

SCPU-204mofuta oa mocheso o phahamengmochini o lahlelang elastomere sa tsoa ntlafatsoa ke k'hamphani ea rona ho ipapisitse le ho ithuta le ho monya mekhoa e tsoetseng pele kantle ho naha, e sebelisoang haholo tlhahiso ea lebili, rabara e koahetsoeng ka rabara, sieve, impeller, mochini oa OA, lebili la skating, buffer, joalo-joalo. , esita le ho kopanya, ts'ebetso e tsitsitseng, ts'ebetso e bonolo, le katleho e phahameng ea tlhahiso, joalo-joalo.

1. Bakeng sa nkho ea thepa ea mofuta oa sandwich, e na le paballo e ntle ea mocheso

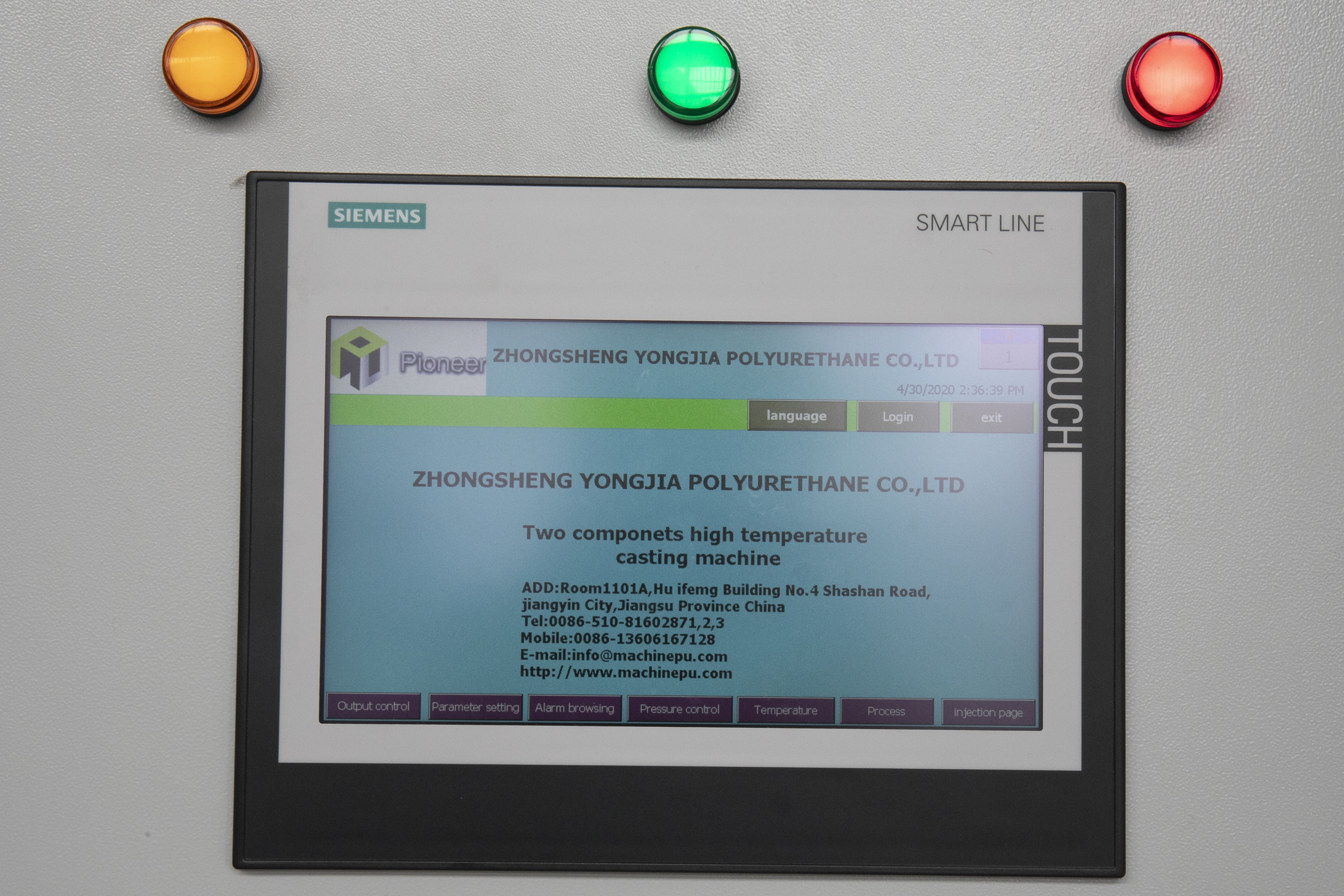

2. Ho amoheloa ha PLC touch screen control panel ea motho-computer ho etsa hore mochine o be bonolo ho o sebelisa le boemo ba ts'ebetso bo ne bo hlakile ka ho feletseng.

3. Ho lokisa hlooho ho laoloa ka ho toba ke mokhoa oa ho sebetsa oa PLC, ho bonolo ho sebetsa.

4. Ho amoheloa ha hlooho e ncha ea ho kopanya ho etsa hore ho kopanya ho be bonolo, ka tšobotsi ea lerata le tlaase, e tiileng le e tšoarellang.

5. Pompo e nepahetseng e phahameng e lebisa ho lekanya ka nepo.

6. Ho bonolo bakeng sa tlhokomelo, ts'ebetso le ho lokisa.

7. Tšebeliso e tlaase ea matla.

Tšela hlooho:

Ho amohela propeller ea lebelo le phahameng la V TYPE e kopanyang hlooho (mokhoa oa ho khanna: Lebanta la V), etsa bonnete ba hore o kopanya ka har'a tekanyo e hlokahalang ea ho tšela le mefuta e fapaneng ea karolelano.Lebelo la motlakase le ile la eketseha ka lebelo la lebili la synchronous, le etsa hore hlooho e kopanyang e potolohe ka lebelo le phahameng ka ho kopanya cavity.Tharollo ea A, B e fetoleloa ho boemo ba ho lahla ka valve ea phetoho e fapaneng, e kena ka har'a champer e kopanyang ka orifice.Ha hlooho ea ho kopanya e ne e le ho potoloha ka lebelo le phahameng, e lokela ho ba le lisebelisoa tse ka tšeptjoang tsa ho tiisa ho qoba ho tšollela thepa le ho netefatsa ts'ebetso e tloaelehileng ea ho beha.

Sistimi ea taolo ea lisebelisoa tsa motlakase:

E entsoe ka sesebelisoa sa motlakase, sesebelisoa sa moea, sehokahanyi sa AC le matla ohle, likarolo tsa taolo ea mocheso joalo ka ho futhumatsa le tse ling.Phetha ts'ebetso ea lisebelisoa hammoho le PLC (nako ea ho tšela le ho hloekisa ka boiketsetso), e le ho netefatsa hore e sebetsa hantle.PLC e na le alamo e phahameng ea khatello e phahameng ho sireletsa pompo ea metering le tube ea thepa tsamaisong ea thepa hore e se ke ea senyeha.Hape withting ea mocheso ka holimo le tlaase meeli ho insure thepa 'tloaelehileng tshebetso tlas'a mocheso tsitsitseng.Phoso ea mocheso oa ± 2 ℃.

| 序 号 Che. | 项 目 Ntho | 技 术 参 数 Tekheniki Parameter |

| 1 | 注射压力 Khatello ea Ente | 0.1-0.6Mpa |

| 2 | 注射流量 Sekhahla sa ho phalla ha ente | 50-130g/s 3-8Kg/min |

| 3 | 混合比范围 Ho kopanya karo-karolelano | 100:6-18(fetohang) |

| 4 | 注射时间 Nako ea ente | 0.5~99.99S(精确到0.01S) 0.5~99.99S (e nepahetseng ho isa ho 0.01S) |

| 5 | 料温控制误差 Phoso ea taolo ea mocheso | ±2℃ |

| 6 | 重复注射精度 Ho nepahala ha ente e phetoang | ±1% |

| 7 | 混合头ho kopanya hlooho | 5000转/分钟 ,强制动态混合 Hoo e ka bang 5000rpm(4600 ~ 6200rpm, e ka fetoloa), ho kopanya ka matla |

| 8 | 料罐容积Bophahamo ba tanka | 220L/30L |

| Mocheso o phahameng oa ho sebetsa | 70-110℃ | |

| B mocheso o phahameng oa ho sebetsa | 110-130℃ | |

| 9 | 清洗罐 Tanka ea ho hloekisa | 20L 304# ts'epe e sa beng le mabali |

| 10 | 计量泵Pompo ea metering | JR50/JR50/JR9 |

| A1 A2Pompo ea meteringphalliso | 50CC/r | |

| B Pompo ea meteringphalliso | 6CC/r | |

| A1-A2-B-C1-C2 LIPUMPU TSE KHOLO LEBELO | 150RPM | |

| A1 A2 lebelo la agitator | 23RPM | |

| 11 | 压缩空气需要量 tlhokeho ya moya e petelitsoeng | 干燥、无油 e omeletseng, ntle le oli P:0.6-0.8MPa Q:600L/min(Ea bareki) |

| 12 | 真空需要量 Tlhokahalo ea vacuum | P:6x10-2Pa(6 BAR) 抽气速率lebelo la ho felloa ke matla:15L/S |

| 13 | 温控系统 Sistimi ea taolo ea mocheso | 加热:18~24KW Ho futhumatsa: 18~24KW |

| 14 | 输入电源 Matla a kenyang | 三相五线mantsoe a mararo terata e mehlano,380V 50HZ |

| 15 | 加热功率 Matla a futhumatsang | TANKIA1/A2: 4.6KW TANKIB: 7.2KW

|

| 16 | Kakaretso ea matla | 34KW |

Lihlahisoa tsa polyurethane li sebelisoa mefuteng e mengata ea likopo le liindasteri.Le hoja karolo e kholo ea maikutlo a rona e le ho tšoara thepa e ngata, konkreite le temo, re ka etsa ho hongata haholo.

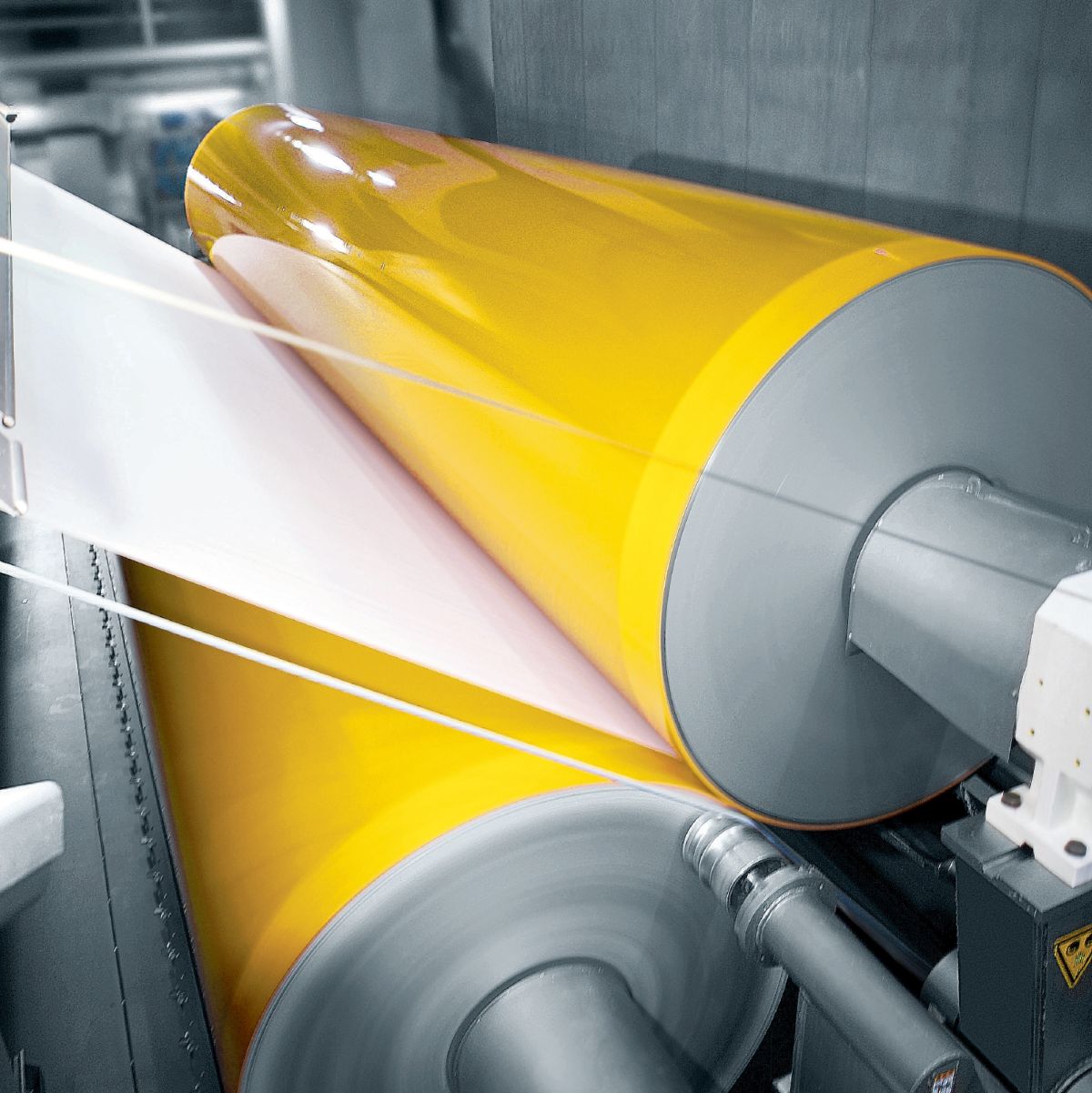

Liindasteri tse ling tseo re atlehileng ho tsona ke liindasteri tsa microelectronics le photovoltaic, moo lirolara tsa rona tse sehang ka terata li sebelisoang ho theheng metsi a silicon bakeng sa ho sebetsa li-silicon chips.Lirolara tsa rona li thusa ho tataisa lithapo tse koahetsoeng ka taemane ho khaola thepa ea silicon.

Urethane Wire Guide Rollers Coating Elastomer Casting Machine bakeng sa mechini ea terata e ntseng e seha terata ea daemane (li-blocks tsa mono/multi silicon hore li be li-wafers)