Multi-component Cast Elastomer Polyurethane Machines (MDI/TDI) YePU Wire Guide Rollers

SCPU-204mhando yepamusoro tembirichaelastomer kukanda muchinaichangobva kuvandudzwa nekambani yedu yakavakirwa pakudzidza uye kutora hunyanzvi hwepamusoro kunze kwenyika, iyo inoshandiswa zvakanyanya mukugadzira vhiri, rabha yakavharwa roller, sieve, impeller, OA muchina, skating vhiri, buffer, nezvimwe. , kunyangwe kusanganisa, kuita kwakagadzikana, kushanda kuri nyore, uye kugadzirwa kwakanyanya, nezvimwe.

1. Kune sandwich type material bucket, ine yakanaka kuchengetedza kupisa

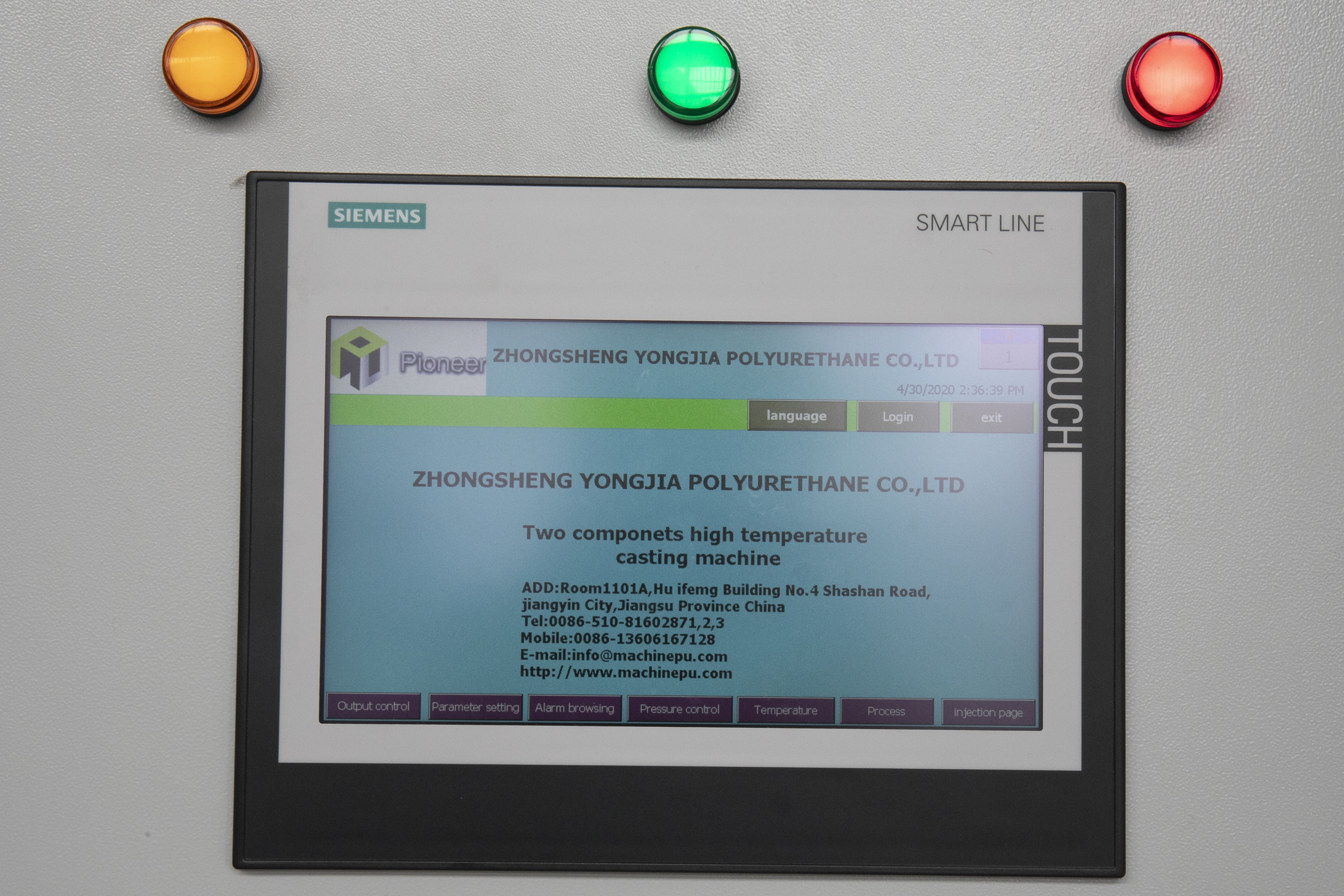

2. Kugamuchirwa kwePLC touch screen yemunhu-computer interface control panel inoita kuti muchina uve nyore kushandisa uye mamiriro ekushanda aive akajeka.

3. Musoro wekugadzirisa unodzorwa zvakananga nePLC operating system, iri nyore kushanda.

4. Kugamuchirwa kwemhando itsva yekusanganisa musoro kunoita kuti kusanganiswa kuenzane, neunhu hwekuderera kweruzha, kusimba uye kusimba.

5. High precision pombi inotungamirira pakuyera nemazvo.

6. Zviri nyore pakugadzirisa, kushanda nekugadzirisa.

7. Kuderera kwesimba rekushandisa.

Dururira musoro:

Kutora yakakwira yekumhanyisa yekucheka propeller V TYPE yekusanganisa musoro (modhi yekutyaira: V bhandi), simbisa kunyangwe kusanganisa mukati mehuwandu hunodiwa hwekudira uye kusanganisa reshiyo renji.Kumhanya kwemota kwakawedzera kuburikidza nekumhanyisa vhiri vhiri, zvichiita kuti musoro wekusanganisa utenderere nekumhanya kukuru mukusanganisa mhango.A, B mhinduro inochinjirwa kune yekukanda nyika neyakasiyana vheruvhu yekushandura, huya mumusanganisi champer kuburikidza ne orifice.Kana musoro wekusanganisa waive wekumhanya zvakanyanya kutenderera, unofanirwa kuve wakashongedzerwa nechisimbiso chekuisa chisimbiso kudzivirira kudira zvinhu uye kuve nechokwadi chekushanda kwakajairwa kwekutakura.

Electrical apparatus control system:

Inoumbwa nemagetsi switch, air switch, AC contactor uye simba rose, kudziyisa kudzora zvinhu sedunhu sekudziya uye nezvimwe.Pedzisa mashandiro emidziyo pamwe nePLC (nguva yekudurura uye otomatiki kuchenesa), kuitira kuti ive nechokwadi chekuti inoshanda zvakanaka.PLC yakashongedzerwa ne Ultra high pressure alarm kuchengetedza metering pombi uye zvinhu chubhu muzvinhu system kubva mukukuvadzwa.Zvakare kudzima tembiricha yekumusoro uye yakaderera miganho yekuisa inshurensi yezvinhu 'zvakajairika kushanda pasi petembiricha yakagadzikana.Kukanganisa kwe tembiricha ye ± 2 ℃.

| 序 号 Aihwa. | 项 目 Item | 技 术 参 数 Technical Parameter |

| 1 | 注射压力 Injection Pressure | 0.1-0.6Mpa |

| 2 | 注射流量 Jekiseni kuyerera mwero | 50-130g/s 3-8Kg/min |

| 3 | 混合比范围 Kusanganisa ratio range | 100:6-18(inochinjika) |

| 4 | 注射时间 Nguva yejekiseni | 0.5~99.99S(精确到0.01S) 0.5~99.99S (chaiyo kusvika 0.01S) |

| 5 | 料温控制误差 Kutadza kutonga tembiricha | ±2℃ |

| 6 | 重复注射精度 Yakadzokororwa jekiseni nemazvo | ±1% |

| 7 | 混合头kusanganisa musoro | 约5000转/分钟 ,强制动态混合 Around 5000rpm(4600 ~ 6200rpm, inochinjika), kumanikidzwa kusanganisa kusanganisa |

| 8 | 料罐容积Tangi volume | 220L/30L |

| Kupisa kwakanyanya kushanda | 70~110℃ | |

| B yakanyanya tembiricha yekushanda | 110~130℃ | |

| 9 | 清洗罐 Kuchenesa tangi | 20L 304# simbi isina ngura |

| 10 | 计量泵Pombi yemamita | JR50/JR50/JR9 |

| A1 A2Pombi yemamitakutama | 50CC/r | |

| B Pombi yemamitakutama | 6CC/r | |

| A1-A2-B-C1-C2 MAPOMBI AKAWANDA KUSIMBISA | 150RPM | |

| A1 A2 agitator kumhanya | 23RPM | |

| 11 | 压缩空气需要量 kudiwa kwemhepo yakamanikidzwa | 干燥、无油 yakaoma, isina mafuta P:0.6-0.8MPa Q:600L/min(Mutengi-muridzi) |

| 12 | 真空需要量 Vacuum zvinodiwa | P:6X10-2Pa(6 BAR) 抽气速率kukurumidza kupera:15L/S |

| 13 | 温控系统 Temperature control system | 加热:18~24KW Kupisa: 18~24KW |

| 14 | 输入电源 Input power | 三相五线zvirevo zvitatu-shanu-waya,380V 50HZ |

| 15 | 加热功率 Simba rekupisa | TANKA1/A2: 4.6KW TANKB: 7.2KW

|

| 16 | Total power | 34KW |

Zvigadzirwa zve polyurethane zvinoshandiswa mumhando dzakasiyana siyana dzekushandisa uye maindasitiri.Kunyange chikamu chikuru chetarisiro yedu chiri pakubata zvinhu zvakawanda, kongiri uye kurima, tinogona kuita zvakawanda.

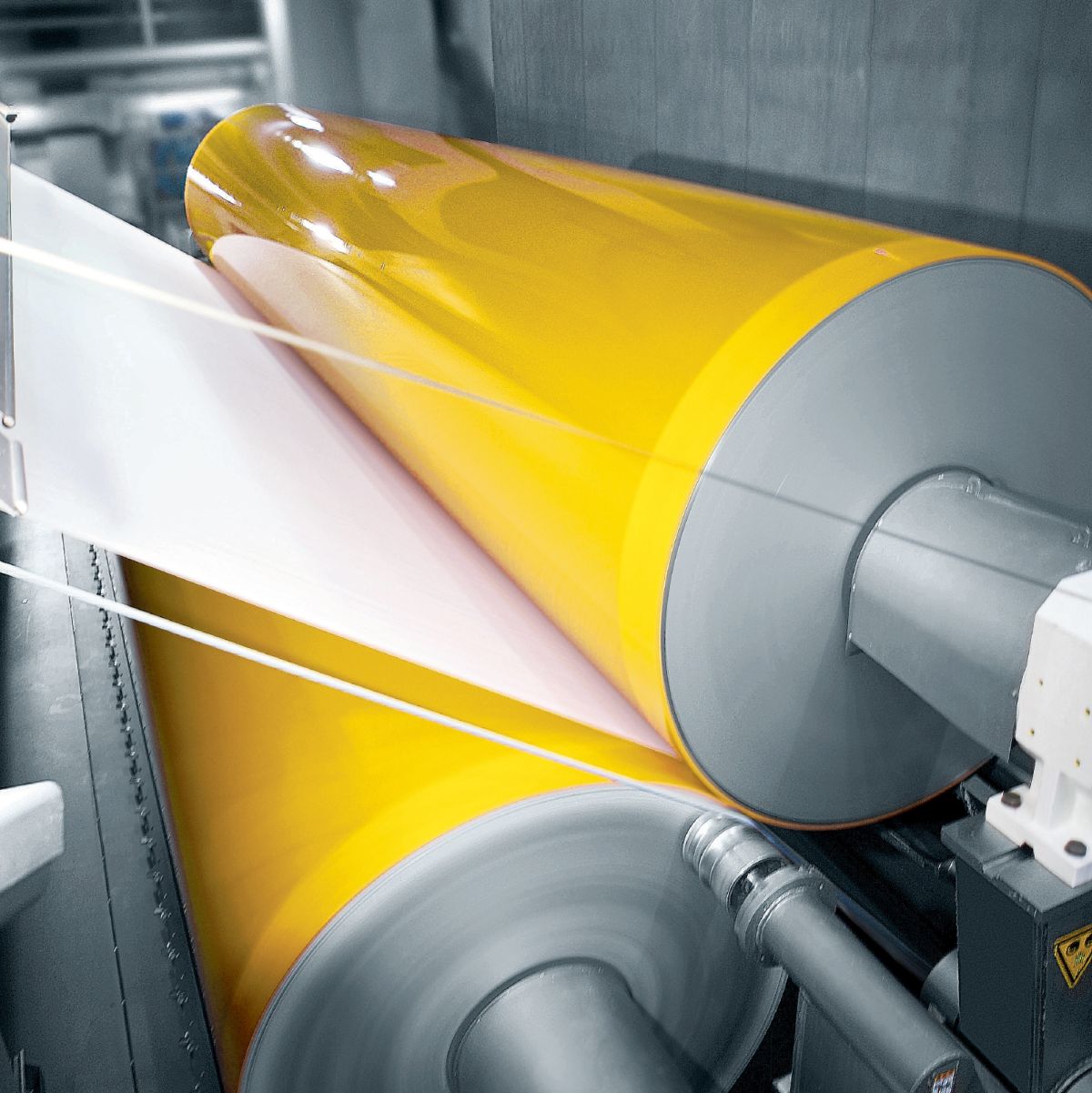

Mamwe maindasitiri atakawana kubudirira maari mamicroelectronics uye photovoltaic industries, uko ma roller edu ekucheka waya anoshandiswa mukugadzira mvura yesilicon yekugadzira silicon chips.Ma roller edu anobatsira kutungamira waya dzakavharwa nedhaimani kutema silicon zvinhu.

Urethane Wire Guide Rollers Coating Elastomer Casting Machine yewaya saw machines mukugadzira madhaimani waya yekucheka (mono/multi silicon blocks into wafers)