Sandwich Panel Coldroom Panel Making Machine High Pressure Foaming Machine

Feature

1. Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2. Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3. Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4. Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5. High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6. Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

Mixing head:

The mixing head adopts floating mechanical seals, and its high shear mixing screw head, which can mix two materials (Polyurethane and Isocyanate) with better performance.The raw materials are stirred at high speed in the mixing chamber by stirring blades to achieve a mixing effect, so that the liquid is uniformly sprayed to form a desired product.

Electrical control system:

Adopting mcgs man-computer interface, setting the injection time,test time and pressure time and etc. Adopting Taiwan Fatek programmable controller and whole foaming machine automatic controlled, make metering unit, hydraulic unit, temp control system, tank agitator, mixing head injection coordinate the work according to the procedures, ensure process efficiency and reliable.

|

Item |

Technical parameter |

|

Foam application |

Rigid Foam Sandwich Panel |

|

Raw material viscosity(22℃) |

POLY ~2500MPas ISO ~1000MPas |

|

Injection pressure |

10-20Mpa(adjustable) |

|

Output (mixing ratio 1:1) |

500~2500g/min |

|

Mixing ratio range |

1:3~3:1(adjustable) |

|

Injection time |

0.5~99.99S(correct to 0.01S) |

|

Material temperature controlling error |

±2℃ |

|

Repeat injection accuracy |

±1% |

|

Mixing head |

Four oil house,double oil cylinder |

|

Hydraulic system |

Output: 10L/min System pressure 10~20MPa |

|

Tank volume |

250L |

|

Temperature control system |

Heat: 2×9Kw |

|

Input power |

Three-phase five-wire 380V |

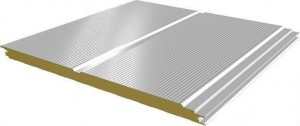

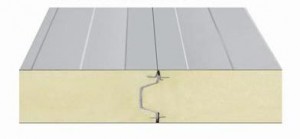

Polyurethane sandwich panel has beautiful appearance and good overall effect. It integrates load-bearing, thermal insulation, fire prevention and waterproofing, and does not require secondary decoration. It is fast and convenient to install, has short construction period, good comprehensive benefits, and has a good cost-effective advantage. It is a kind of A highly efficient and energy-saving building envelope material with a wide range of uses and great potential.