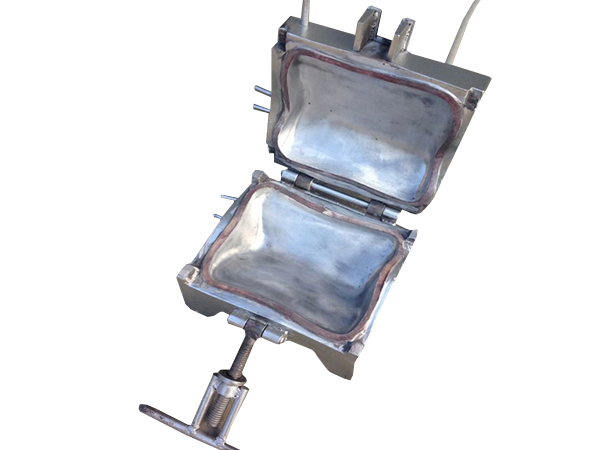

PU Memory Foam Pillow Mold

The flexible foam is an elastic polyurethane that, when fully cured, forms a tough, wear-resistant rubber foam component. The parts made with this PU Pillow Mold have an integral rubber skin with excellent cosmetic results and require almost no further processing.

Our Plastic mould advantages:

1)ISO9001 ts16949 and ISO14001 ENTERPRISE, ERP management system

2)Over 16 years in precision plastic mould manufacturing, collected rich experience

3)Stable technical team and frequent training system, middle management people are all working for over 10 year in our shop

4)Advanced matching equipment, CNC center from Sweden, Mirror EDM and JAPAN precision WIRECUT shots

Our professional one-stop plastic mould custom service:

1)Mold design service and Image design special for our customer

2)Plastic injection mold making, two shot injection mold, gas assisted mold

3)Precision plastic molding:two shot molding, precision plastic molding and gas assisted molding

4)Plastic Secondary operation, like Silk-screening, UV, PU painting, Hot stamping, Laser engraving, Ultrasonic welding, Plating etc.

Different shape Pillow Molds are available.

|

Mold Type |

Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Main services | Prototypes, Mold design, Mold making, Mold tesing,low volume/high volume plastic production |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PP,PU,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, Resin, PET,PS,TPE/TPR etc |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine |

| Month Production | 100 sets/month |

| Mold Packing | standard exporting Wooden case |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Certificate | ISO 9001:2008 |

| Lead time | 25~30 days |

The memory pillow has the following advantages:

1. Absorb impact. When the pillow is on top, it feels like floating on the water or in the clouds, and the skin feels no pressure; it is also called zero pressure. Sometimes when we use ordinary pillows, we will press the auricle, but using slow rebound pillows will not appear This situation.

2. Memory deformation. The ability of automatic shaping can fix the head and reduce the possibility of stiff neck; the ability of automatic shaping can properly fill the shoulder gap, avoid the common problem of air leakage in the shoulder quilt, and effectively prevent cervical spine problems.

3. Anti-bacteria and anti-mite. The slow rebound sponge inhibits the growth of mold and expels the irritating odor caused by the growth and growth of mold. When there is sweat and saliva, it becomes more prominent.

4. Breathable and moisture-absorbing. Since each cell unit is interconnected, it has excellent moisture absorption performance and is also breathable.