PU Elastomer Casting Machine Polyurethane Dispensing Machine For Universal Wheel

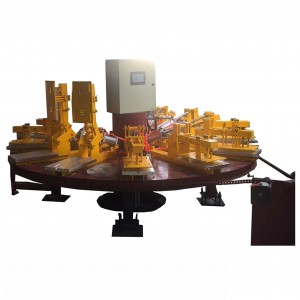

PU elastomer casting machine is used to produce castable polyurethane elastomers with MOCA or BDO as chain extenders. PU elastomer casting machine is suitable for manufacturing various kinds of CPUs such as seals, grinding wheels, rollers, screens, impellers, OA machines, wheel pulleys, buffers, etc. product.

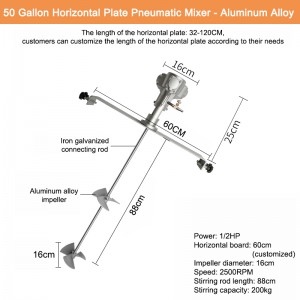

High temperature resistant low-speed high-precision metering pump, accurate metering, and the random error is within ± 0.5%.

The material output is regulated by frequency converter and frequency conversion motor, with high precision pressure and simple and fast speed ratio control.

High performance mixing device, adjustable pressure, synchronous and accurate material output and uniform mixing; New mechanical seal structure to avoid backflow problem.

Special mixing head high-efficiency vacuum device to ensure that the product is free of bubbles.

The heat transfer oil adopts electromagnetic heating mode, which is efficient and energy-saving; Multipoint temperature control system, stable temperature, random error < ± 2 ℃.

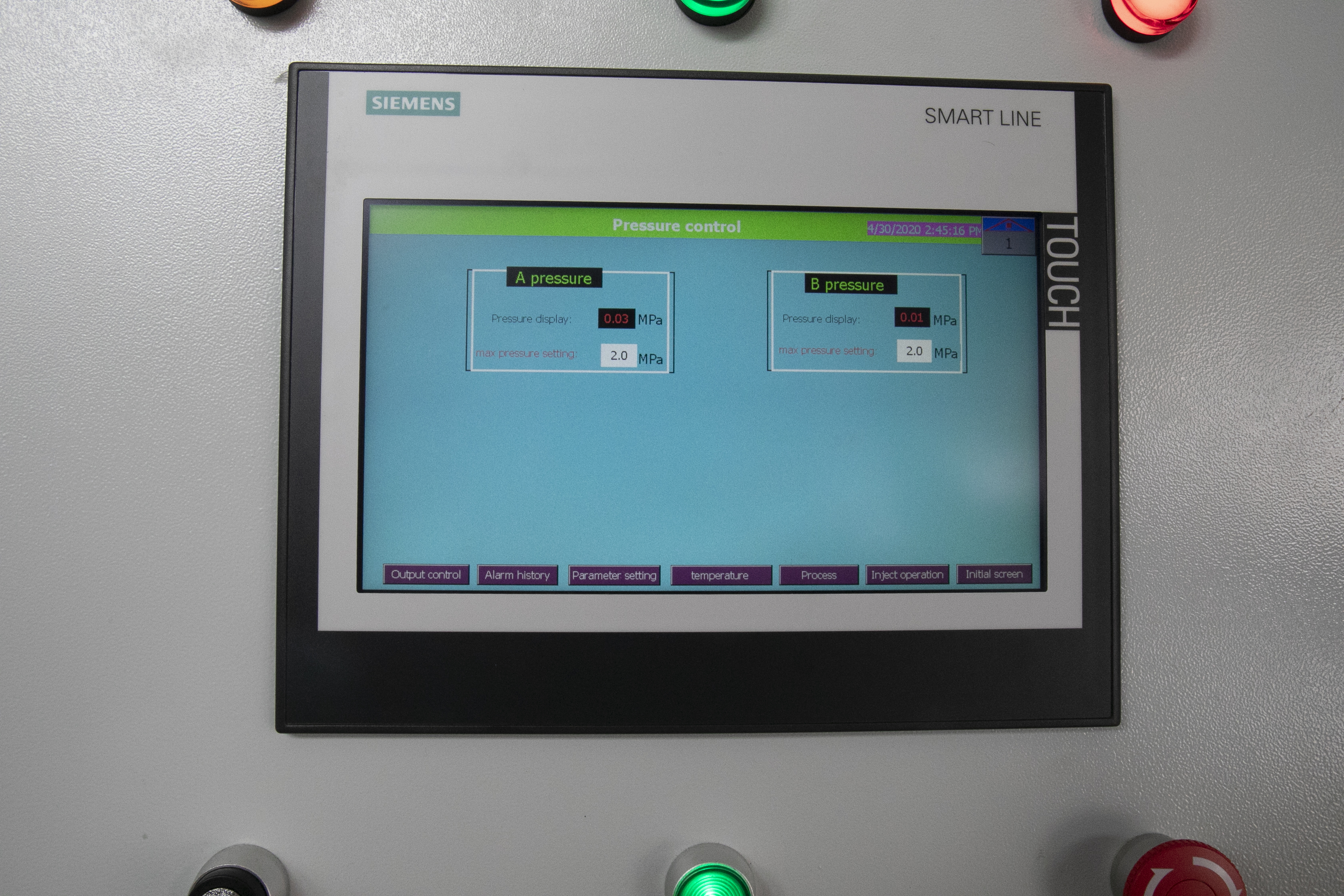

It adopts PLC and touch screen man-machine interface to control pouring, automatic cleaning and flushing, air purification and stability performance.

Strong operability, can automatically identify, diagnose, alarm abnormal conditions and display abnormal factors.

|

Item |

Technical Parameter |

|

Injection Pressure |

0.01-0.1Mpa |

|

Injection flow rate |

85-250g/s 5-15Kg/min |

|

Mixing ratio range |

100:10~20(adjustable) |

|

Injection time |

0.5~99.99S (correct to 0.01S) |

| Temperature control error |

±2℃ |

|

Repeated injection precision |

±1% |

|

Mixing head |

Around 6000rpm, forced dynamic mixing |

|

Tank volume |

250L /250L/35L |

|

Metering pump |

JR70/ JR70/JR9 |

|

Compressed air requirement |

Dry, oil free P:0.6-0.8MPa Q:600L/min(Customer-owned) |

|

Vacuum requirement |

P:6X10-2Pa Speed of exhaust:15L/S |

|

Temperature control system |

Heating: 31KW |

|

Input power |

Three-phrase five-wire,380V 50HZ |

|

Rated power |

45KW |

|

Swing arm |

Fixed arm, 1 meter |

|

Volume |

About 2000*2400*2700mm |

|

Color (selectable) |

Deep blue |

|

Weight |

2500Kg |