PU Earplug Making Machine Polyurethane Low Pressure Foaming Machine

The machine is highly precise chemical pump, accurate and durable.Constant speed motor, frequency converter speed, stable flow, no running ratio.The whole machine is controlled by PLC, and the human-machine touch screen is simple and convenient to operate. Automatic timing and injection, automatic cleaning, automatic temperature control.High precision nose, light and flexible operation, no leakage.

- Low-speed high-precision metering pump, accurate proportioning, and the measurement accuracy error does not exceed +0.5%;

- The flow and pressure of raw materials are adjusted by frequency conversion motor with frequency conversion, with high precision and simple and fast proportional adjustment;

- Using three-layer storage tank, stainless steel inner tank, sandwich heating, outer insulation layer, adjustable temperature, safety and energy saving;

- Using PLC, touch screen man-machine interface to control equipment pouring, automatic cleaning and air flushing, stable performance, strong operability, abnormal conditions

- It will automatically identify, diagnose and alarm, and display abnormal factors;

- The mixing device is equipped with a pressure balance device, which can eliminate the flow error, improve the accuracy, and ensure the product has no macroscopic bubbles.

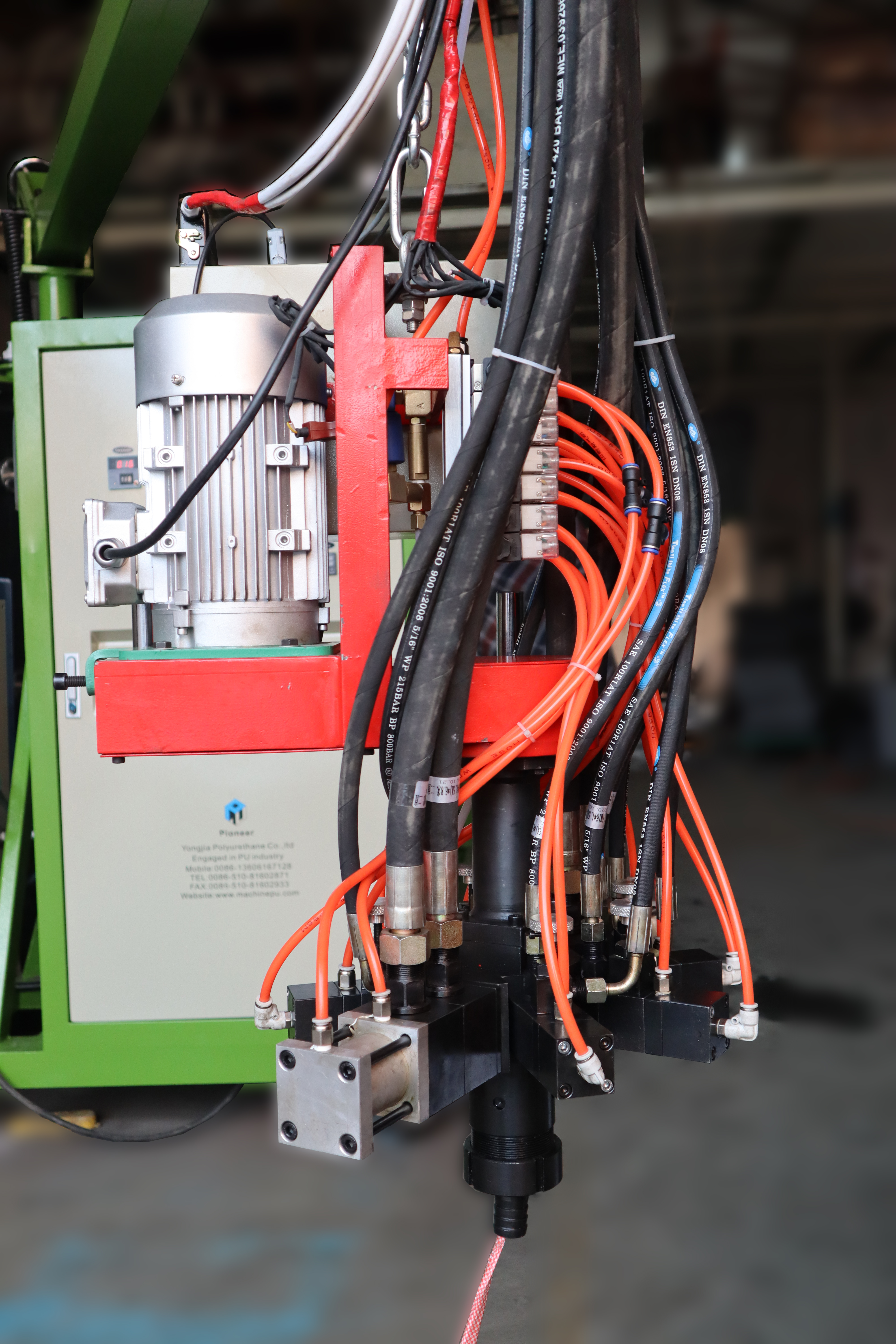

Mixing device(pouring head):

Adopting floating mechanical seal device, high shearing spiral mixing head to make sure the even mixing within required adjusting range of casting mixing ratio. Motor speed is accelerated and frequency controlled through triangle belt so to realize the high speed rotation of mixing head in mixing chamber.

Electrical cotrol system:

Composed of Power switch, air switch,A.C. Contactor and whole machine engine power, heat lamp control element line,digital display temperature controller, digital display manometer, digital display tachometer, PC programmable controller(pouring time and automatic cleaning) to keep machine in good condition.manometer equipped with overpressure alarm to keep metering pump and material pipe from damage due to overpressure.

|

Item |

Technical parameter |

|

Foam application |

Flexible Foam Seat Cushion |

|

Raw material viscosity(22℃) |

POL ~3000CPS ISO ~1000MPas |

|

Injection flow rate |

80-450g/s |

|

Mixing ratio range |

100:28~48 |

|

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

Tank Volume |

120L |

|

Input power |

Three-phase five-wire 380V 50HZ |

|

Rated power |

About 11KW |

|

Swing arm |

Rotatable 90°swing arm, 2.3m (length customizable) |

|

Volume |

4100(L)*1300(W)*2300(H)mm, swing arm included |

|

Color( customizable) |

Cream-colored/orange/deep sea blue |

|

Weight |

About 1000Kg |