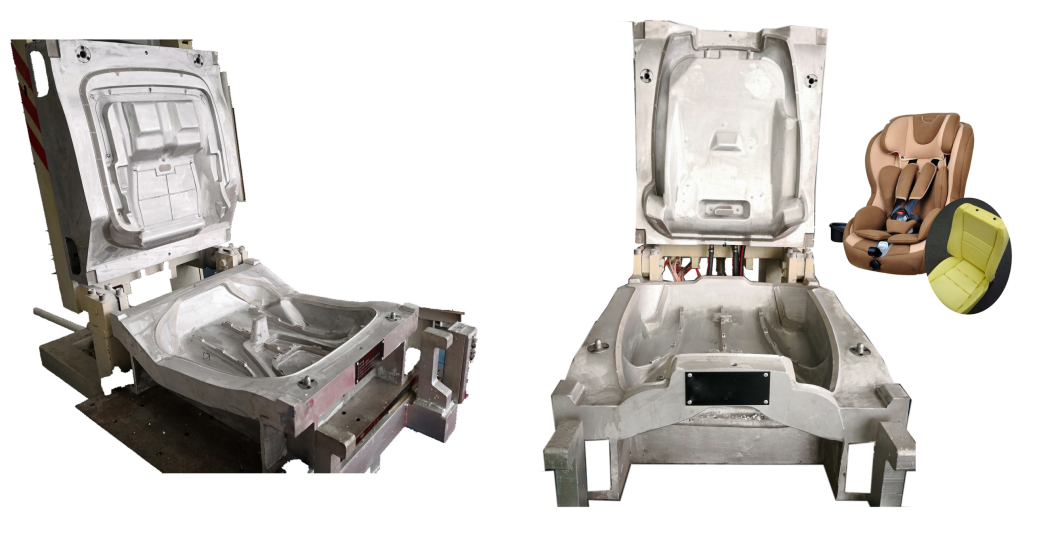

PU Car Seat Cushion Molds

Our molds can be widely used to make car seat cushions, backrests, child seats, sofa cushions for daily use seats, etc.

Our car seat Injection Mold Mould advantages:

1) ISO9001 ts16949 and ISO14001 ENTERPRISE, ERP management system

2) Over 16 years in precision plastic mould manufacturing, collected rich experience

3) Stable technical team and frequent training system, middle management people are all working for over 10 year in our shop

4) Advanced matching equipment, CNC center from Sweden, Mirror EDM and JAPAN precision WIRECUT

Our professional one-stop plastic mould custom service:

1) car seat Injection Mold Mould design service and Image design special for our customer

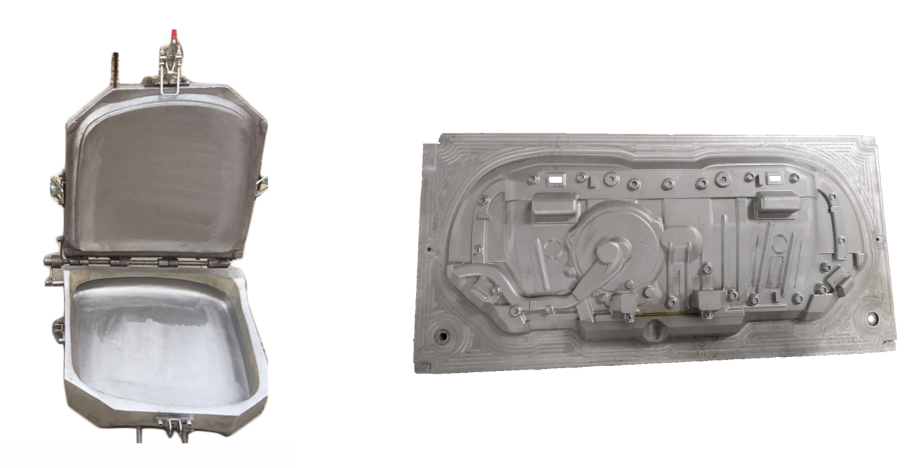

2) Plastic injection mold making, two shot injection mold,gas assisted mold

3) Precision plastic molding:two shot molding, precision plastic molding and gas assisted molding

4)Plastic Secondary operation, like Silk-screening, UV, PU painting, Hot stamping, Laser engraving, Ultrasonic welding, Plating etc.

|

Mold Type |

Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc |

| Main services | Prototypes, Mold design, Mold making, Mold tesing,low volume/high volume plastic production |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PP,PU,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine |

| Month Production | 100 sets/month |

| Mold Packing | standard exporting Wooden case |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Certificate | ISO 9001:2008 |

| Lead time | 25~30 days |