Polyurethane Wood Imitation Rigid Foam Photo Frame Molding Machine

Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, polyurethane and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

Product Features of High Pressure PU Machine:

1.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2.Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

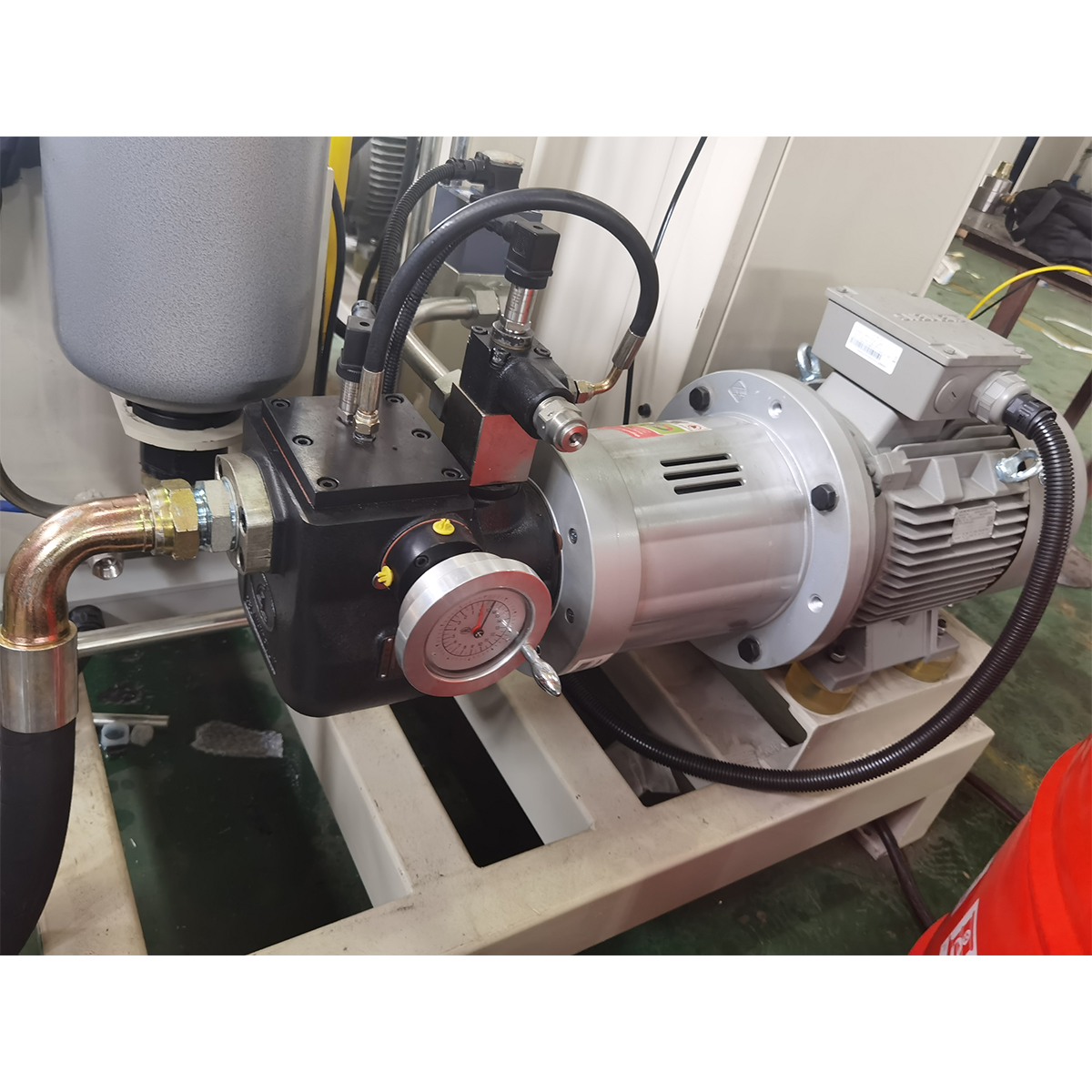

3.Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4.Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5.High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6.Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

A set of high pressure control device, used for adjust and control the working pressure and setting the pressure between 6MPa to 22MPa, when the pressure over the range,the equipment malfunction alarm and displayed the fault message of higher/lower pressure.

Filter is used for material filter,adopts precision self-cleaning filter, so to avoid frequent disassembly, time saving and efficient.

Mixing head adopts L type automatic self-cleaning mixing head, needle type nozzle adjustable, V type jet orifice, High-pressure collisional mixing principle ensure mixing effectual.

Electric control system adopts man-computer interface, setting the injection time,test time and pressure time and etc.

Chiller,Used to supply cooling water to cooling unit,refrigeration capacity 38700Kcal/h ;(options)

| No. | Item | Technical parameter |

| 1 | Foam application | Decoration Crown Moldings |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPasISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 160~800g/s |

| 5 | Mixing ratio range | 1:5~5:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/minSystem pressure 10~20MPa |

| 11 | Tank volume | 250L |

| 12 | Input power | Three-phase five-wire 380V |

Features of Mirror frame manufacturer light mirror frame:

1. Made of polyurethane material: made by casting mold and is different from wooden frame.

2. Have feature of wood: can be digged, nailed and cutted mirror frames

3. Different color finish: like silver, ivory,black, walnut, cherry, ash, brown, antique gold or other colors are available.

4. Have much new design including the traditional ornate frame and contemporary style frame.

5. Customized designs, sizes and packages are accepted.

6. Mounted with painting, mirror for wall decoration or be made as photo frame for family pictures.

7. Durable use and environmentally friendly: water-proof, moisture-proof and mildew-proof.

[2020] Polyurethane Foaming Machine For Furniture Imitation Wood Mirror Frame Faux Stone