Polyurethane Table Edge Banding Machine

The full name is polyurethane. A polymer compound. It was made by O. Bayer in 1937. Polyurethane has two types: polyester type and polyether type. They can be made of polyurethane plastics (mainly foam plastics), polyurethane fibers (known as spandex in China), polyurethane rubber and elastomers.

Soft polyurethane (PU) mainly has a thermoplastic linear structure, which has better stability, chemical resistance, resilience and mechanical properties than PVC foam materials, and has less compression deformation. Good thermal insulation, sound insulation, shock resistance and anti-virus performance. Therefore, it is used as packaging, sound insulation and filter materials.

Taking advantage of these characteristics of polyurethane, our company has introduced the application of polyurethane desk and chair edge.

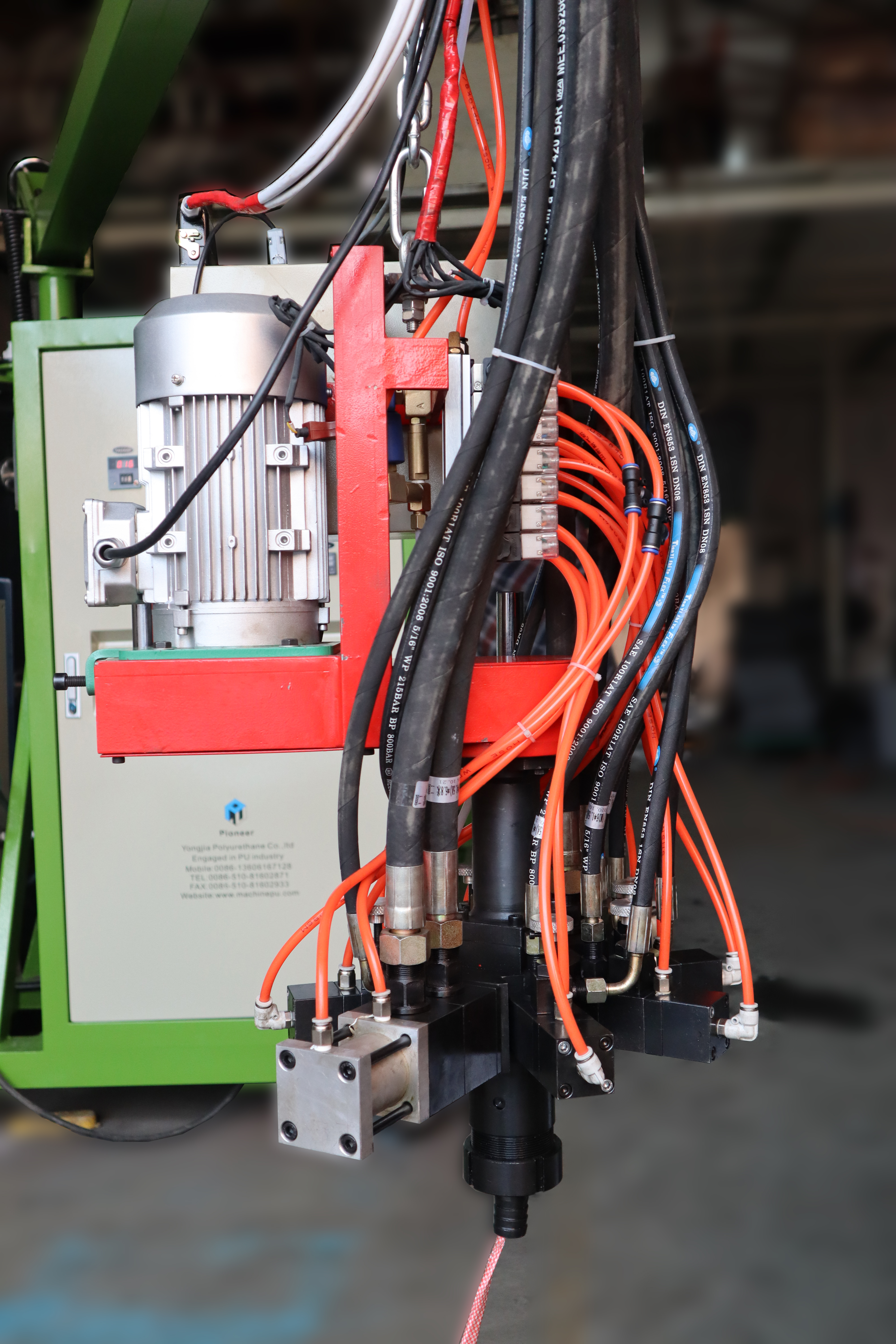

Our polyurethane foaming machine is the best machine for making table and chair edging. The first is its accurate measurement. It uses a low-speed high-precision metering pump. When the material temperature, pressure and viscosity fluctuate, the mixing ratio remains unchanged to achieve the highest rate.

The pouring head has advanced structure, reliable performance and easy operation. The maintenance is simple, and can be used for three-dimensional movement before, after, left and right, and up and down; after the * is the computer controlled pouring volume and automatic cleaning.

The polyurethane filling and foaming machine is controlled by a computer controller. The computer controller uses today’s advanced MCU unit embedding technology. It has on-time*, easy operation and easy maintenance. The alarm relay prompts the completion of the previous injection and prepares for the next injection.

|

No. |

Item |

Technical Parameter |

|

1 |

Foam application |

Flexible foam |

|

2 |

Raw material viscosity(22℃) |

POL ~3000CPS ISO ~1000MPas |

|

3 |

Injection Output |

80-450g/s |

|

4 |

Mixing ratio range |

100:28~48 |

|

5 |

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

6 |

Tank Volume |

120L |

|

7 |

Metering pump |

A pump: GPA3-40 Type B Pump: GPA3-25 Type |

|

8 |

Compressed air requirement |

dry, oil free P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

|

9 |

Nitrogen requirement |

P:0.05MPa Q:600NL/min(Customer-owned) |

|

10 |

Temperature control system |

heat :2×3.2Kw |

|

11 |

Input power |

three-phrase five-wire,380V 50HZ |

|

12 |

Rated power |

about 11KW |

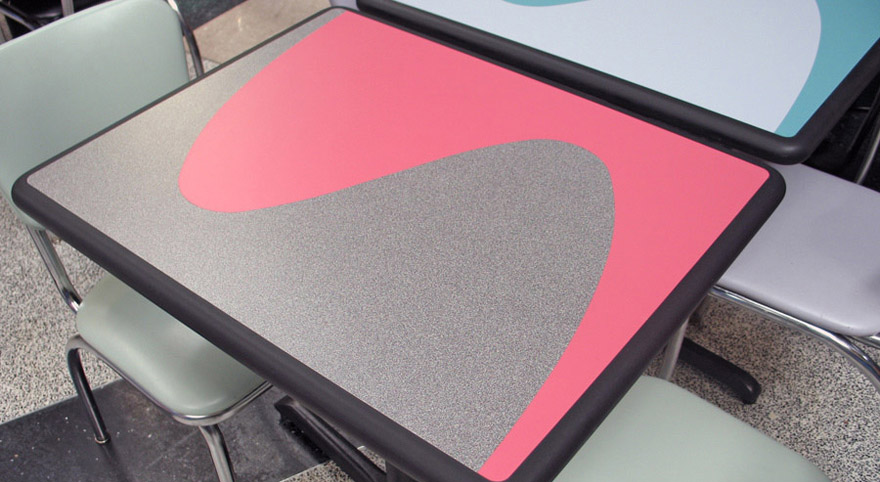

A polyurethane edge combined with a laminate top, this table top is easy to maintain and long lasting. Hygienic seamless polyurethane molding process completely seals top surface, core and bottom liner for cleanliness and durability. Colors are ultra violet light stable and chemical resistant. Color goes clear though polyurethane edge material for exceptional long term wear resistance.

We think the table is perfect for contemporary dining applications where durability needs to dovetail into clean modern style. It is also applied in classroom desk and office table for protecting people from hurt. Our polyurethane foaming machine is the best machine for making table and chair edging.