Polyurethane Mattress Making Machine PU High Pressure Foaming Machine

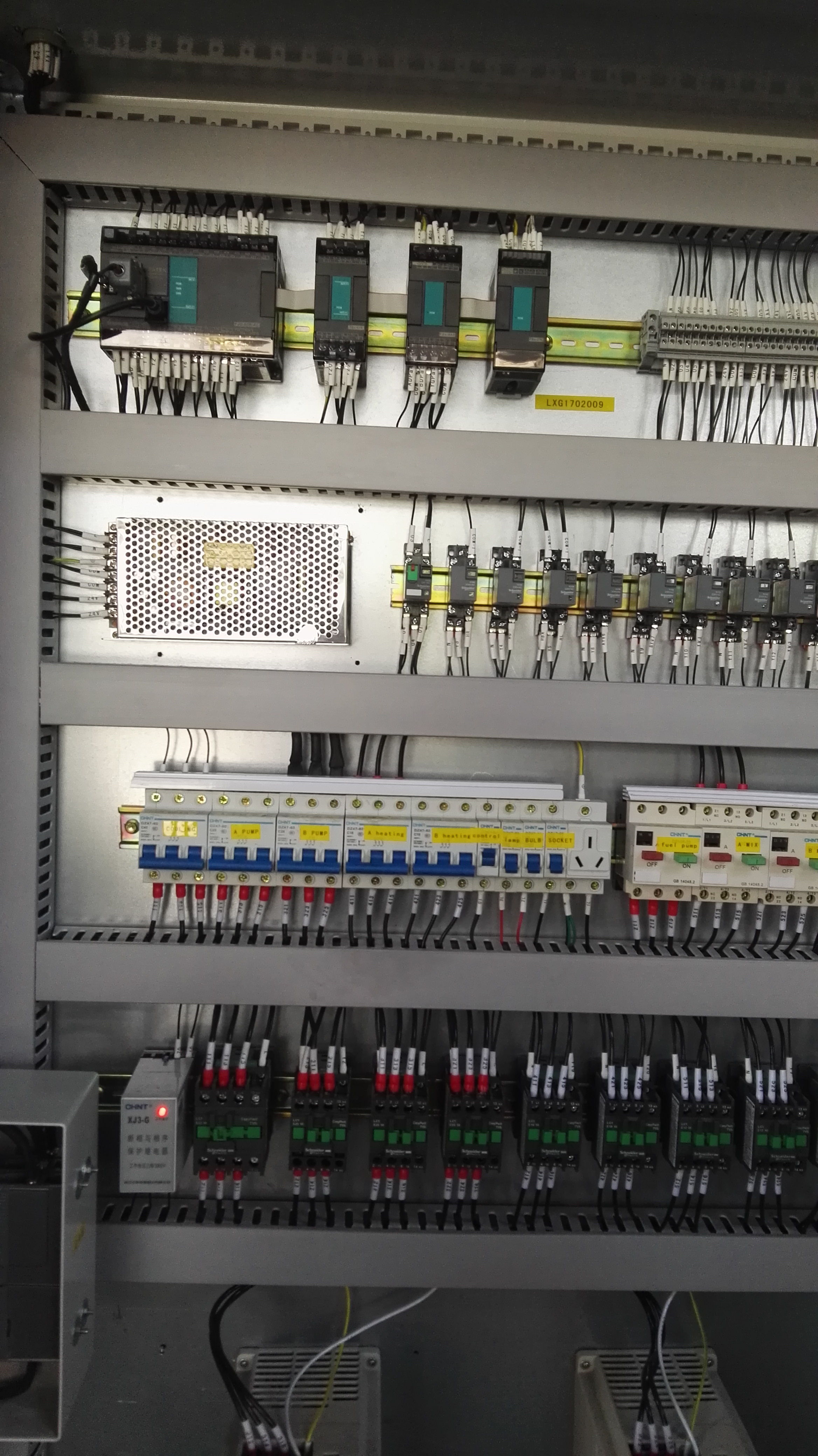

1.Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors;

2.High-performance mixed device, accurately synchronous material壯陽藥

s output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

3.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

4.Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5.Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

6.Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

1. Process parameters and display: metering pump speed, injection time, injection pressure, mixing ratio, date, temperature of raw materials in the tank, fault alarm and other information are displayed on a 10-inch touch screen.

2. The high and low pressure switching function of the foaming machine adopts the self-developed pneumatic three-way rotary valve to switch. There is an operation control box on the gun head. The control box is equipped with a station display LED screen, an injection button, emergency Stop button, cleaning rod button, sampling button. And it has a delayed automatic cleaning function. One-click operation, automatic execution.

3. The equipment is equipped with production management control software, which is convenient for production management. Mainly refers to the proportion of raw materials, injection times, injection time, station formula and other data.

|

Item |

Technical parameter |

|

Foam application |

Flexible Foam Mattress Foam |

|

Raw material viscosity(22℃) |

POLY ~2500MPas ISO ~1000MPas |

|

Injection pressure |

10-20Mpa(adjustable) |

|

Output (mixing ratio 1:1) |

375~1875g/min |

|

Mixing ratio range |

1:3~3:1(adjustable) |

|

Injection time |

0.5~99.99S(correct to 0.01S) |

|

Material temperature controlling error |

±2℃ |

|

Repeat injection accuracy |

±1% |

|

Mixing head |

Four oil house,double oil cylinder |

|

Hydraulic system |

Output: 10L/min System pressure 10~20MPa |

|

Tank volume |

280L |

|

Temperature control system |

Heat: 2×9Kw |

|

Input power |

Three-phase five-wire 380V |

PU high preasure foaming machine is mainly suitable for producing all kinds of high-rebound, slow-rebound, self-skinning and other polyurethane plastic molding products. Such as: car seat cushions, sofa cushions, car armrests, sound insulation cotton, memory pillows and gaskets for various mechanical appliances, etc.

The most prominent point of the polyurethane foam mattress during use is its slow rebound, which can change with the change of human pressure, maintain the proper shape, perfectly fit the body curve, and reduce the pressure of the mattress on the body.