Polyurethane Glue Coating Machine Adhesive Dispensing Machine

Feature

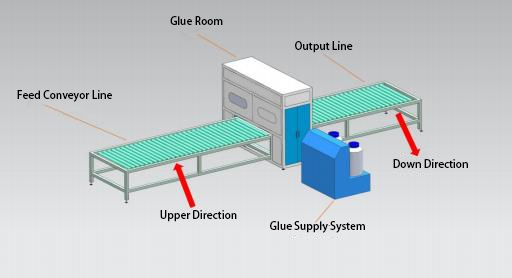

1. Fully automatic laminating machine, the two-component AB glue is automatically mixed, stirred, proportioned, heated, quantified, and cleaned in the glue supply equipment, The gantry type multi-axis operation module completes the glue spraying position, glue thickness, glue length, cycle times, automatic reset after completion, and starts automatic positioning.

2. The company makes full use of the advantages of global technology and equipment resources to realize high-quality matching of product parts and components in domestic and foreign markets, and develop A series of processing and production equipment with high technical level, reasonable configuration, exquisite layout and high cost performance.

Polyurethane glue coating machine is a kind of equipment for coating polyurethane glue. It uses roller or mesh belt to convey polyurethane glue, and by adjusting the pressure and speed of the glue roller, the glue is evenly coated on the required substrate. Polyurethane glue has high strength, wear resistance and corrosion resistance, and is widely used in the manufacture of automobiles, aerospace, building materials and other fields.

The advantages of the polyurethane glue spraying machine are uniform coating, large coating area, fast coating speed, and easy operation. The laminating machine can also be integrated with other equipment, such as coating machines, cutting machines, etc., to realize the construction of automated production lines, thereby improving production efficiency and product quality.

In short, the polyurethane glue spraying machine is a very important coating equipment, which is widely used in various industries and provides an important guarantee for the manufacture and upgrading of products.

| No. | Item | Technical Parameters |

| 1 | A B Glue Proportion Accuracy | ±5% |

| 2 | equipment power | 5000W |

| 3 | Flow accuracy | ±5% |

| 4 | Set glue speed | 0-500MM/S |

| 5 | Glue output | 0-4000ML/min |

| 6 | structure type | Glue supply device + gantry module assembly type |

| 7 | control method | PLC control program V7.5 |

Application

The application of polyurethane glue laminating machine is very extensive. In the automobile manufacturing industry, polyurethane glue spraying machines are used to coat sealant, anti-noise glue, vibration-absorbing glue, etc. inside and outside the car to improve the safety and comfort of the car. In the aerospace manufacturing industry, polyurethane glue applicators are used to apply sealants, structural adhesives, coatings, etc. of aircraft and spacecraft to improve their durability and flight performance. In the building material manufacturing industry, polyurethane glue spraying machines are used to coat thermal insulation materials, waterproof materials, etc., to improve the thermal insulation and waterproof properties of building materials.