Polyurethane Gel Memory Foam Pillow Making Machine High Pressure Foaming Machine

★Using high-precision inclined-axis axial piston variable pump, accurate measurement and stable operation;

★Using high-precision self-cleaning high-pressure mixing head, pressure jetting, impact mixing, high mixing uniformity, no residual material after use, no cleaning, maintenance-free, high-strength material manufacturing;

★The white material pressure needle valve is locked after balance to ensure that there is no pressure difference between the black and white material pressure

★Magnetic coupling coupling adopts high-tech permanent magnet control, no temperature rise and no leakage;

★The mixing head adopts double proximity switch control to realize precise injection;

★The raw material timing cycle function ensures that the raw material does not crystallize when the equipment is stopped;

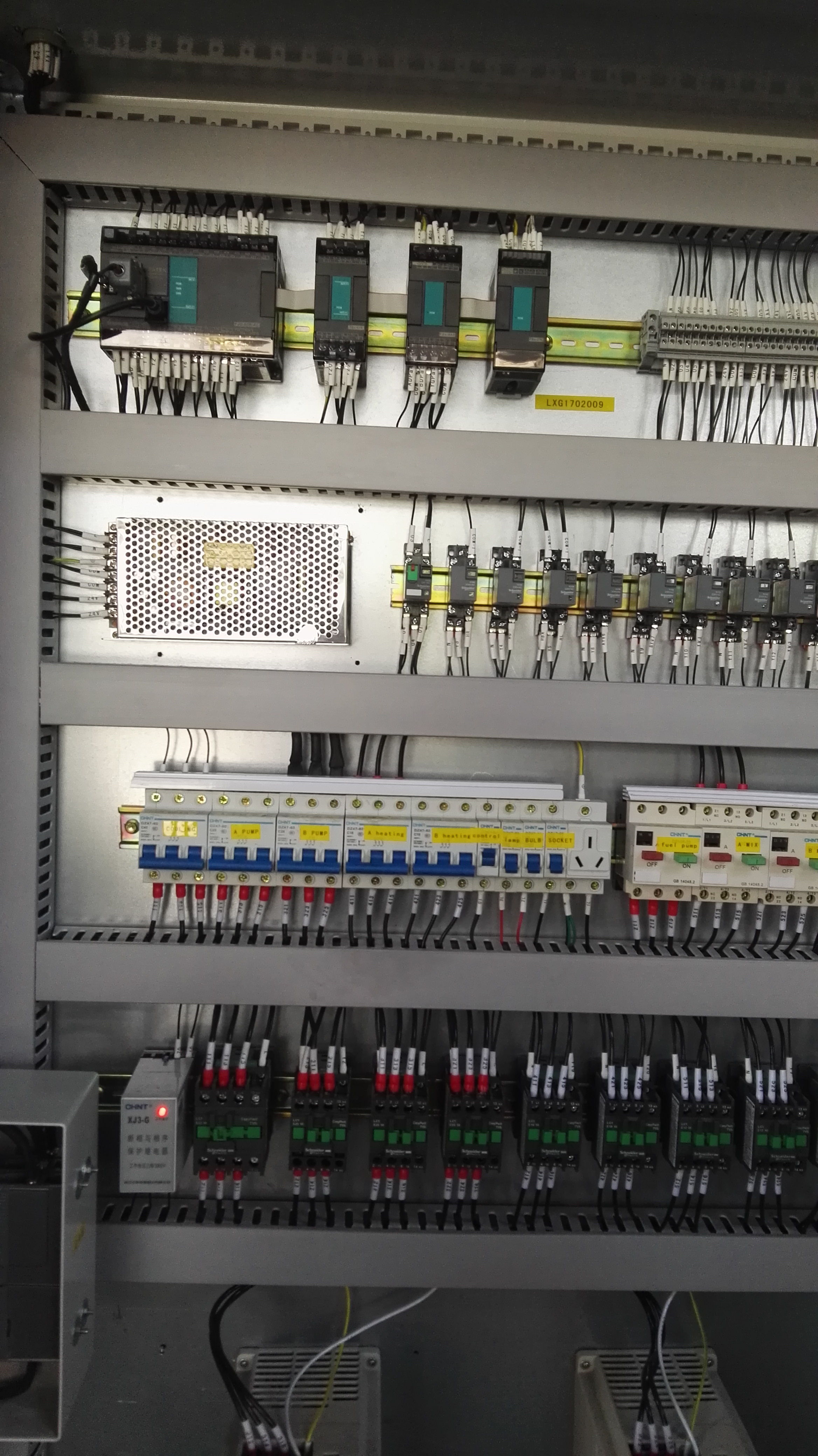

★Fully digital modular integrated control of all I-art processes, accurate, safe, intuitive, intelligent and user-friendly.

|

Item |

Technical parameter |

|

Raw material viscosity(22℃) |

POLY ~2500MPas ISO ~1000MPas |

|

Injection pressure |

10-20Mpa(adjustable) |

|

Output (mixing ratio 1:1) |

375~1875g/min |

|

Mixing ratio range |

1:3~3:1(adjustable) |

|

Injection time |

0.5~99.99S(correct to 0.01S) |

|

Material temperature controlling error |

±2℃ |

|

Repeat injection accuracy |

±1% |

|

Mixing head |

Four oil house,double oil cylinder |

|

Hydraulic system |

Output: 10L/min System pressure 10~20MPa |

|

Tank volume |

280L |

|

Temperature control system |

Heat: 2×9Kw |

|

Input power |

Three-phase five-wire 380V |