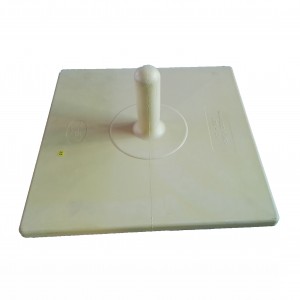

Polyurethane Foam Production Line PU Foaming Machine For PU Trowel

Feature

plastering trowel mould

1. Light weight: good resilience and tenacity, light and hard,.

2. Fire-proof: reach the standard of no combustion.

3. Water-proof: no moisture absorbing, water permeation and mildew arising.

4. Anti-erosion: resist acid and alkali

5. Environment protection: using polyester as raw material to avoid lumbering

6. Easy to clean

7. OEM serviece: We have employed R&D center for research, advanced production line, professional engineers and workers,service for you.Also we have successfully developed a design partnership with our OEM clients. Because of the unique high load capacity,high elasticity, wear and tear resistance of our casters and wheels, we are widely chosen by many customers in Middle East,European, South Asia, South America, ect.

Low Pressure Foaming Machine

Low-pressure polyurethane foam machines support a number of applications in which lower volumes, higher viscosities, or differing levels of viscosity between the various chemicals used in a mixture are required. To that point, low-pressure polyurethane foam machines are also an ideal choice when multiple streams of chemicals need to be treated differently prior to mixture.

| Item | Technical parameter |

| Foam application | Rigid foam |

| raw material viscosity(22℃) | Polyol~3000CPS ISO ~1000MPas |

| Injection output | 16-65g/s |

| Mixing ration range | 100:50~150 |

| mixing head | 2800-5000rpm, forced dynamic mixing |

| Tank volume | 120L |

| metering pump | A pump: JR12 Type B Pump: JR12 Type |

| compressed air needed | dry, oil free, P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

| Nitrogen requirement | P:0.05MPa Q:600NL/min(Customer-owned) |

| Temperature control system | heat:2×3.2Kw |

| input power | three-phase five-wire 380V 50HZ |

| Rated power | About 9KW |

| swing arm | Rotatable swing arm, stretch out 2.3m(length customizable) |

| volume | 4100(L)*1250(W)*2300(H)mm, swing arm included |

| Color( customizable) | Cream-colored/orange/deep sea blue |

| Weight | 1000Kg |