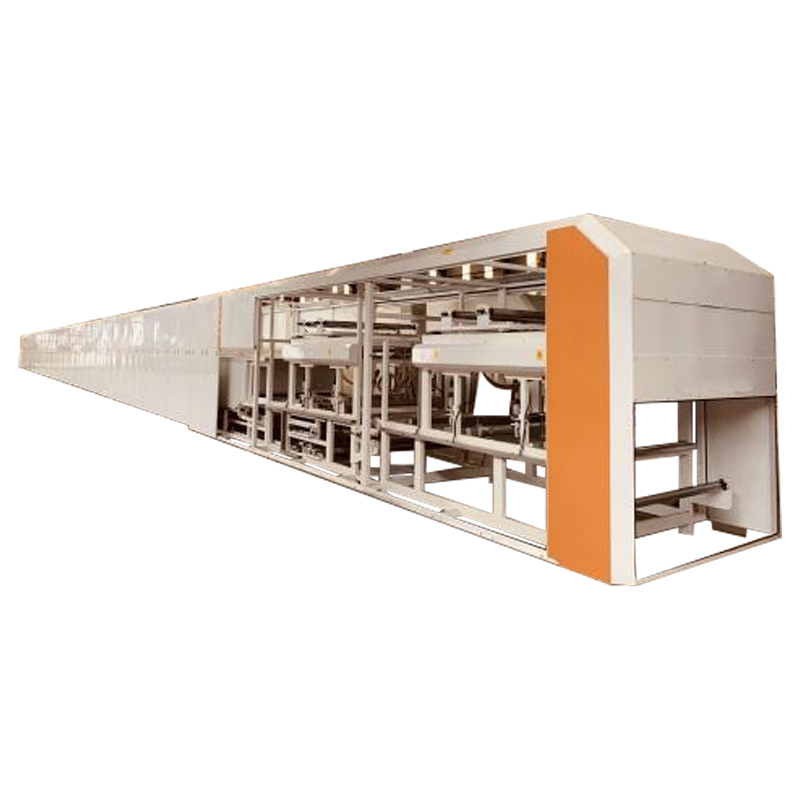

Polyurethane Faux Stone Panel Flexible Soft Clay Ceramic Tile Production Line

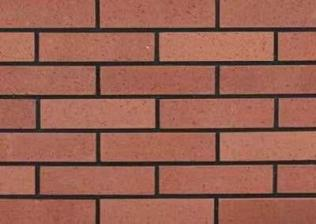

Model-pressed soft ceramic, particularly in split bricks, slate, antique wood grain bricks, and other variants, currently dominates the market with its substantial cost advantages. It has garnered significant favor in both civilian and commercial construction, especially in nationwide urban revitalization projects, showcasing its lightweight, safe, and easy-to-install qualities. Notably, it does not require on-site spraying or cutting, reducing environmental pollution such as dust and noise, ensuring minimal disturbance, and offering exceptional cost-effectiveness. Its future potential is promising.

Furthermore, this set of production assembly line technology pioneers a dedicated Internet of Things (IoT) control system within the industry. This system enables remote management of the production line’s operational status, facilitating remote post-sales services, programming, and more. This innovation allows production facilities to be established globally, ensuring uninterrupted, batch production operations 24 hours a day. This greatly enhances production efficiency and operational convenience, promising significant prospects for future development.

- Unified parameters for the entire pipeline:

1. The height of the conveying working surface of the assembly line: 800±25mm.

2. Operation direction: Facing the operation surface, materials enter from the left and come out from the right.

3. Electricity parameters: three-phase five-wire system, three-phase 380V, 50Hz.

- Soft porcelain spraying host

Chain plate transmission, French Schneider Electric control, Japanese Mitsubishi servo system, Japanese Mitsubishi PLC, Fanyi high-definition touch screen, Taiwan Yadeke solenoid valve, Taiwan Shangyin guide rail plus slider, 2 special flexible slurry spray guns, screw pump, hopper And 1 set of independent intelligent control cabinet;

Note: Waste paint mist collection and emissions are connected to the VOC purification system purchased by your company for purification and emissions;

Remarks: Party A needs to make its own waste paint mist collection room and connect it to the VOC exhaust gas purification system, and the customer makes its own mixing and feeding platform.

- Natural gas or steam heat source drying tunnel high temperature kiln

1. Constant temperature hot air drying system on the slurry surface, zone temperature setting, adjustable temperature, adjustable wind speed, zone dehumidification design, efficient drying, energy saving, 5cm rock wool external insulation, drying tunnel is heated on all sides, top, bottom, left and right, and all sides are evenly heated It has thermal insulation design and low energy consumption, including internal pipes, valves, natural gas burners, hot blast stoves and other auxiliary equipment.

2. Conveying system: chain plate conveying, plus reverse mold endless belt deviation correction system and feeding guide device, silicone endless belt anti-falling system, and automatic rewinding device;

3. Working temperature 150℃, operating temperature 130℃;

Polyurethane soft porcelain is a multifunctional building decoration material that is widely used in various building environments, including interior walls, exterior walls, subway tunnels, hospitals, pharmaceutical factories, commercial and residential buildings, villas, municipal construction, schools, art Museums, museums, libraries, civil decoration, entertainment and leisure venues, etc. Its main features include: