Polyurethane Culture Stone Faux Stone Panels Making Machine PU Low Pressure Foaming Machine

Feature

1. Accurate measurement: high-precision low-speed gear pump, the error is less than or equal to 0.5%.

2. Even mixing: The multi-tooth high shear mixing head is adopted, and the performance is reliable.

3. Pouring head: special mechanical seal is adopted to prevent air leakage and prevent material pouring.

4. Stable material temperature: The material tank adopts its own heating temperature control system, the temperature control is stable, and the error is less than or equal to 2C

5. The whole machine adopts 7-inch touch screen and PLC module control, which can pour regularly and quantitatively and automatically clean with air flushing.

Advantages Of PU Culture Stone

1. Mix the real with the fake

The mold is made of real stone, so even if the raw material is pressed and colored by the mold, it still has an uneven surface and a hard color like a stone, which is very realistic and can almost be faked.

2. Lightweight and durable

Don’t look at it like a stone, think it is as heavy as a stone, in fact, the pu stone is very light, and it can be installed by a single person! However, light weight does not mean that it is not strong, and the PU stone is resistant to acid, sunscreen and has a long service life.

3. Strong plasticity

As a new cross-border material, Pu stone has rich shapes and strong plasticity! Almost all cultural stone modeling pu stones are available.

4. Small security risks

Compared with the original ecological rubble, pu stone is not only light in weight, low in consumption, but also has much lower safety hazards. If you happen to be a stone lover, but are concerned about safety issues, pu stone is the best alternative.

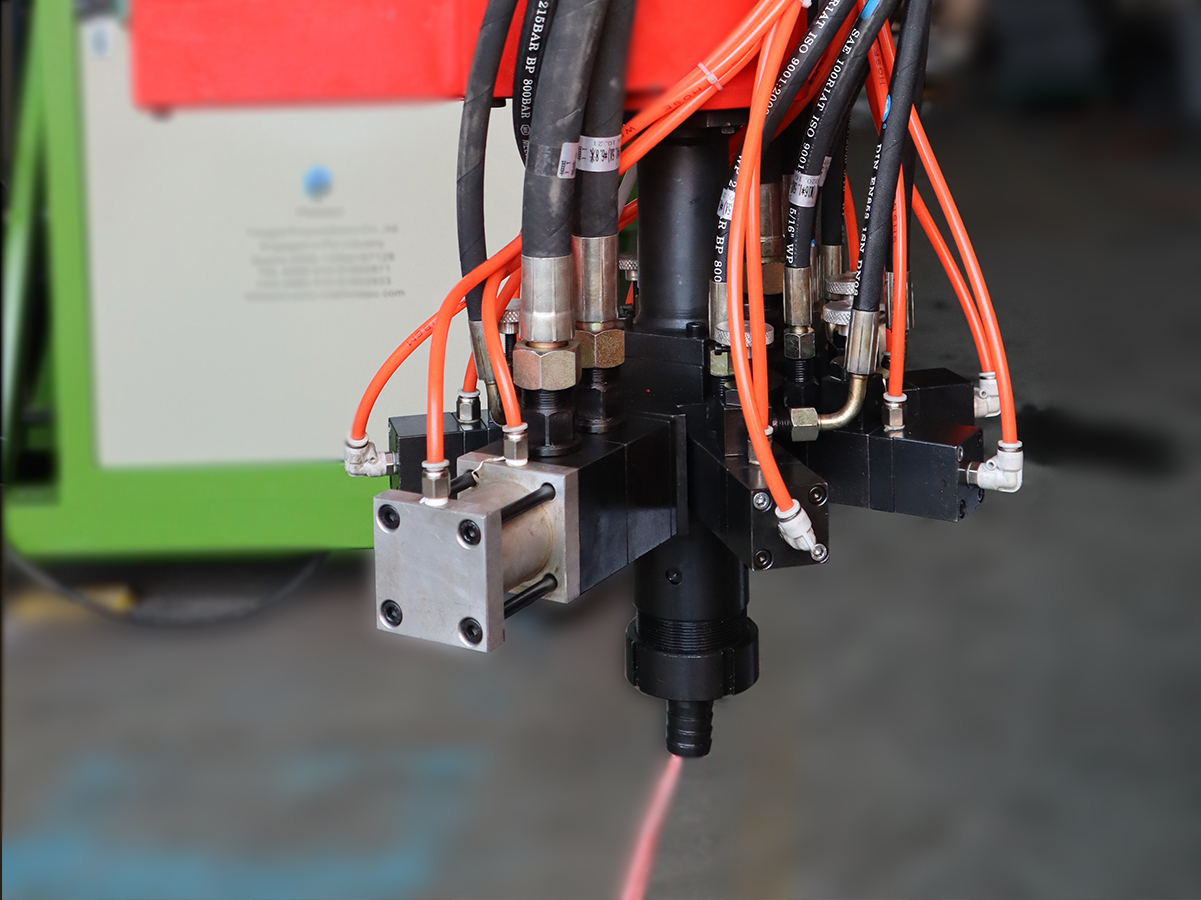

Mixing head:

Stirring mixing, mixing evenly Using a new type of injection valve, precision pouring mixing head automatic cleaning can add color, instantly switch different colors Mixing head single controller, easy to operate

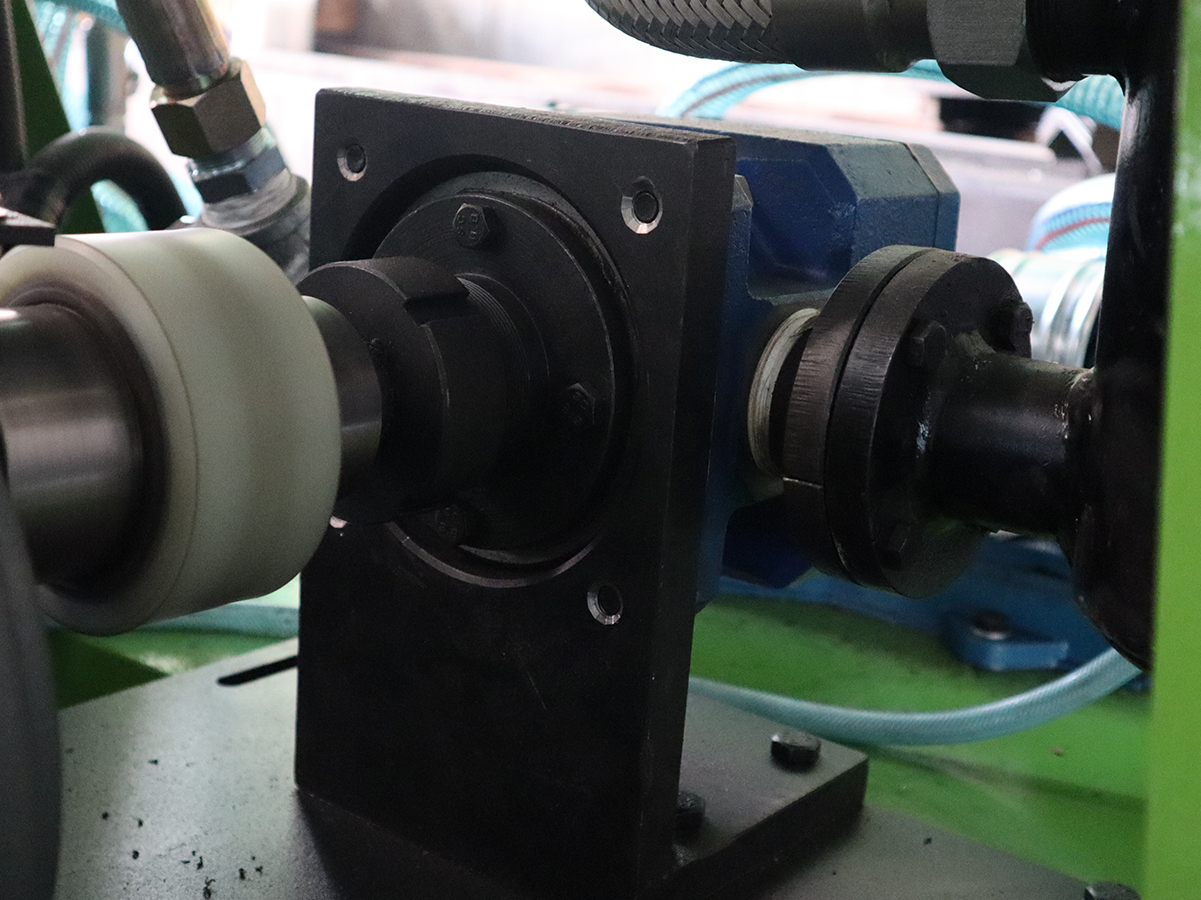

Metering unit:

High precision low speed gear pump

The flow and ratio are adjustable, the frequency conversion motor drives the pump and the motor through the coupling, and the DOP seal components

Storage and Temperature Regulation:

Jacket-type tank with visual level gauge Digital pressure gauge for pressure control Resistive heater for component temperature adjustment (chiller can be pre-mixed) The tank is equipped with a stirrer for uniform mixing

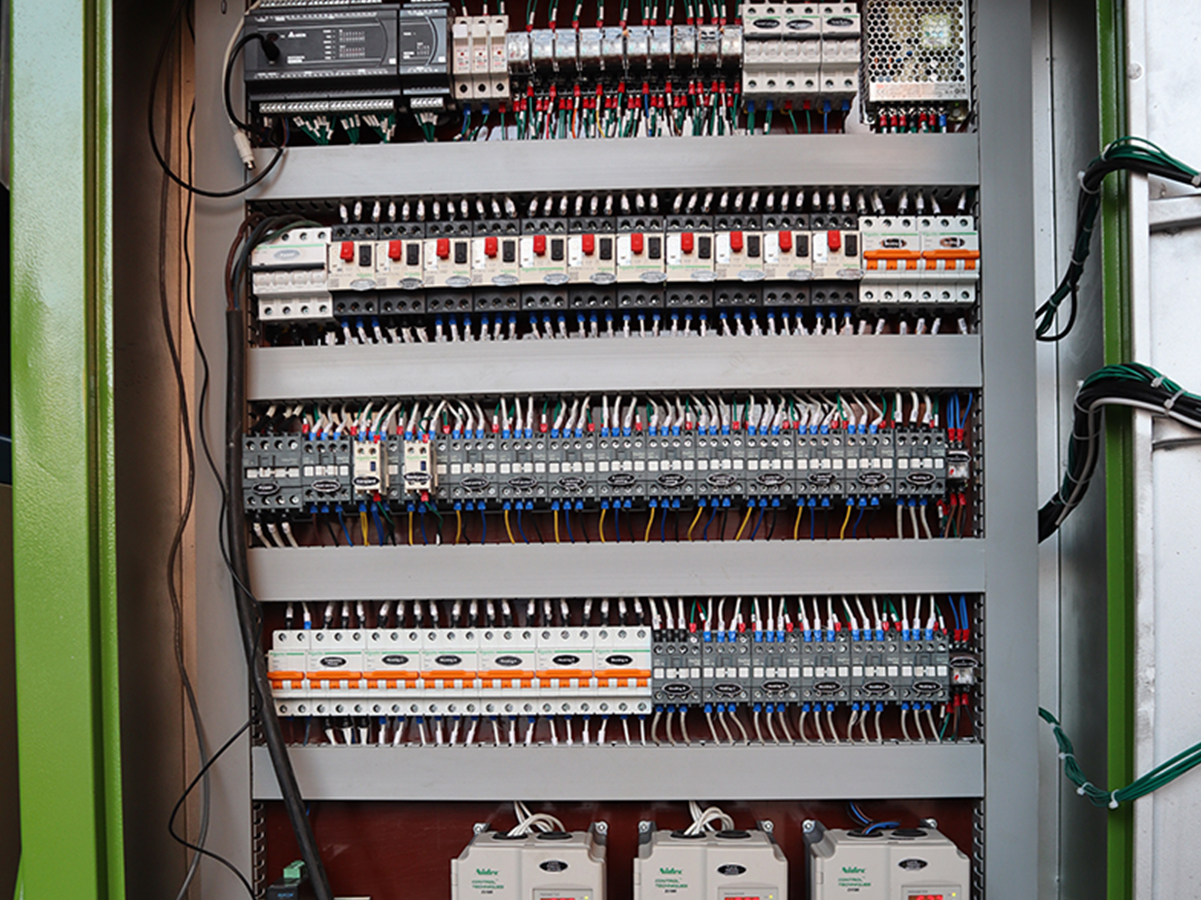

Electrical control system:

Simple and friendly to use, can realize parameter setting, pouring time, temperature control, cleaning control and other functions Sound and light alarm alarm function, failure shutdown protection.

|

Item |

Technical parameter |

|

Foam application |

Integral Skin Foam Seat |

|

Raw material viscosity(22℃) |

POL ~3000CPS ISO ~1000MPas |

|

Injection flow rate |

26-104g/s |

|

Mixing ratio range |

100:28~48 |

|

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

Tank Volume |

120L |

|

Input power |

Three-phase five-wire 380V 50HZ |

|

Rated power |

About 9KW |

|

Swing arm |

Rotatable 90°swing arm, 2.3m (length customizable) |

|

Volume |

4100(L)*1300(W)*2300(H)mm, swing arm included |

|

Color( customizable) |

Cream-colored/orange/deep sea blue |

|

Weight |

About 1000Kg |