Polyurethane Car Seat Low Pressure PU Foaming Machine

1. Accurate measurement: high-precision low-speed gear pump, the error is less than or equal to 0.5%.

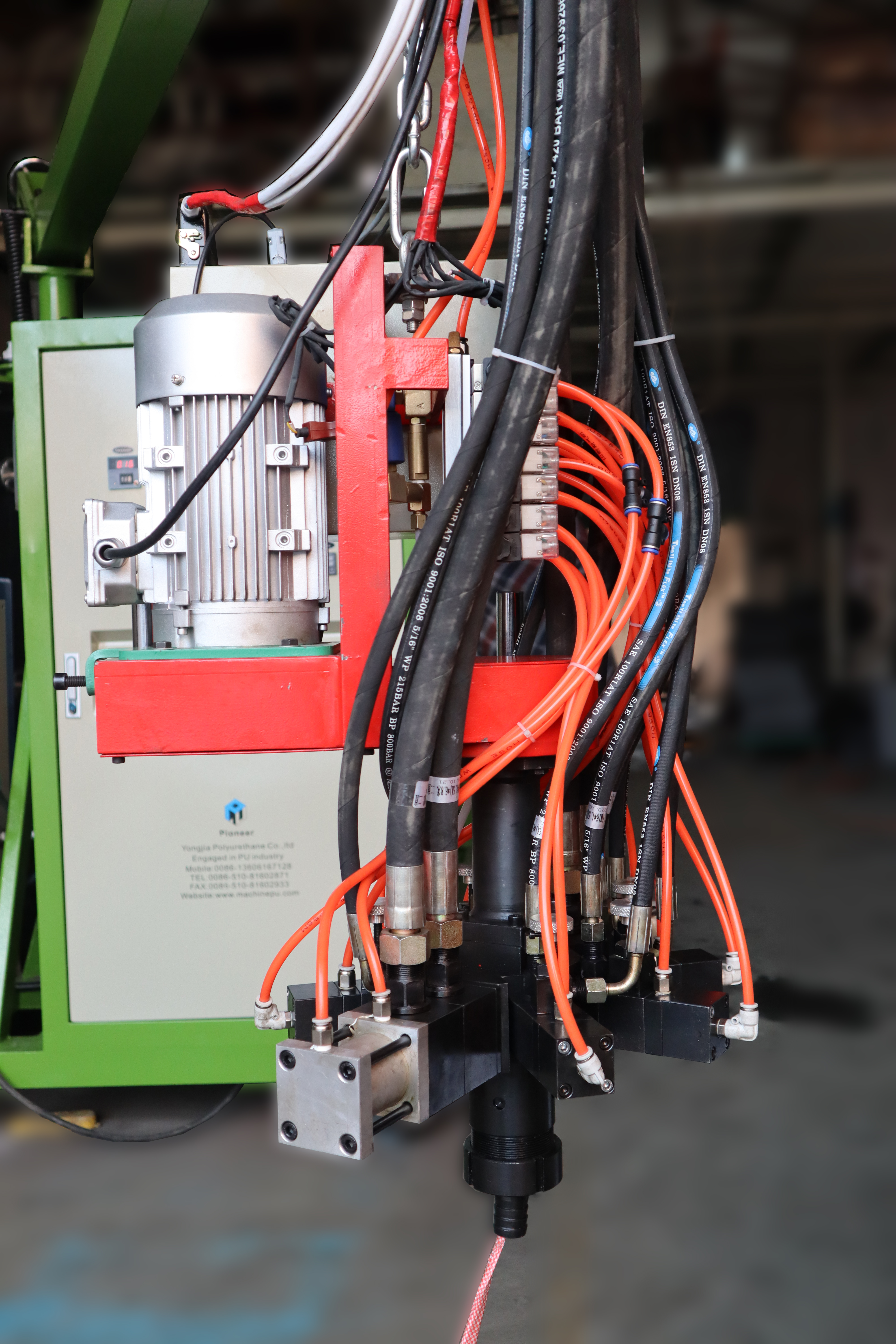

2. Even mixing: The multi-tooth high shear mixing head is adopted, and the performance is reliable.

3. Pouring head: special mechanical seal is adopted to prevent air leakage and prevent material pouring.

4. Stable material temperature: The material tank adopts its own heating temperature control system, the temperature control is stable, and the error is less than or equal to 2C

5. The whole machine adopts touch screen and PLC module control, which can pour regularly and quantitatively and automatically clean with air flushing.

Mixing device(pouring head):

Adopting floating mechanical seal device, high shearing spiral mixing head to make sure the even mixing within required adjusting range of casting mixing ratio. Motor speed is accelerated and frequency controlled through triangle belt so to realize the high speed rotation of mixing head in mixing chamber.

Electrical cotrol system:

Composed of Power switch, air switch,A.C. Contactor and whole machine engine power, heat lamp control element line,digital display temperature controller, digital display manometer, digital display tachometer, PC programmable controller(pouring time and automatic cleaning) to keep machine in good condition.manometer equipped with overpressure alarm to keep metering pump and material pipe from damage due to overpressure.

|

Item |

Technical parameter |

|

Foam application |

Flexible Foam Seat Cushion |

|

Raw material viscosity(22℃) |

POL ~3000CPS ISO ~1000MPas |

|

Injection flow rate |

80-450g/s |

|

Mixing ratio range |

100:28~48 |

|

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

Tank Volume |

120L |

|

Input power |

Three-phase five-wire 380V 50HZ |

|

Rated power |

About 11KW |

|

Swing arm |

Rotatable 90°swing arm, 2.3m (length customizable) |

|

Volume |

4100(L)*1300(W)*2300(H)mm, swing arm included |

|

Color( customizable) |

Cream-colored/orange/deep sea blue |

|

Weight |

About 1000Kg |