Multi-component Cast Elastomer Polyurethane Machines (MDI/TDI) For PU Wire Guide Rollers

SCPU-204 type high temperature elastomer casting machine is newly developed by our company based on learning and absorbing advanced techniques abroad, which is widely employed in the production of wheel, rubber covered roller, sieve, impeller, OA machine, skating wheel, buffer, etc. This machine has high repeat injection precision, even mixing, stable performance, easy operation, and high production efficiency, etc.

1. For sandwich type material bucket, it has good heat preservation

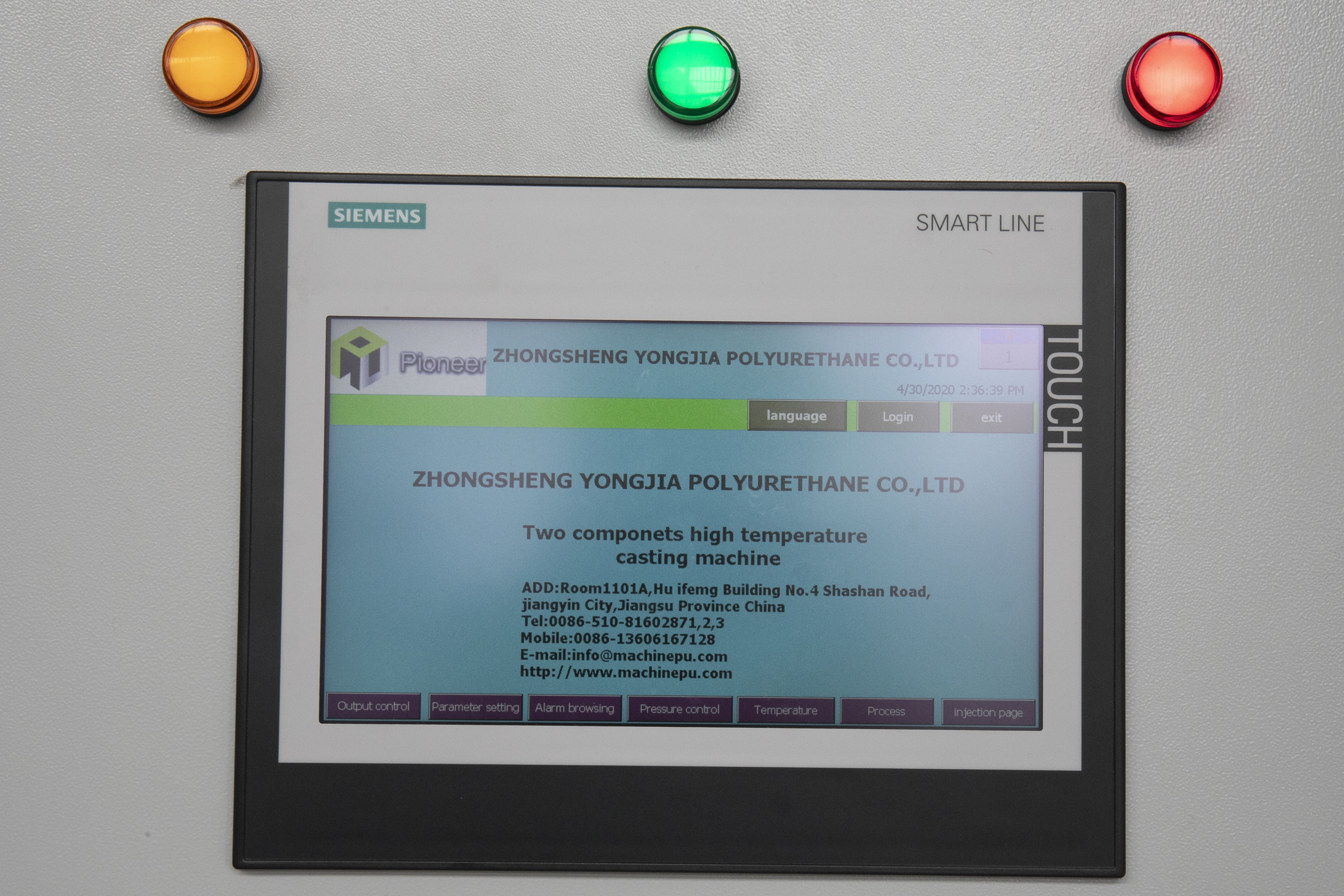

2. The adoption of PLC touch screen human-computer interface control panel makes the machine easy to use and the operating situation was absolutely clear.

3. Head fixing controlled directly by PLC operating system,easy of operation.

4. The adoption of new type mixing head makes the mixing even, with the characteristic of low noise, sturdy and durable.

5. High precision pump lead to measuring accurately.

6. Easy for maintenance, operation and repair.

7. Low energy consumption.

Pour head:

Adopting high speed cutting propeller V TYPE mixing head (drive mode: V belt), ensure even mixing within the required pouring amount and mixing ratio range. Motor speed increased through a synchronous wheel speed, making the mixing head rotate with high speed in mixing cavity. A, B solution are switched to casting state by their respective conversion valve, come into the mixing champer through orifice. When the mixing head was at high speed rotation, it should be equipped with reliable sealing device to avoid pouring material and ensure the normal operation of the bearing.

Electrical apparatus control system:

Composed of power switch, air switch, AC contactor and the entire power, heating control elements circuit like heating and others. Accomplish equipment operation together with PLC (pouring time and automatic cleaning), so as to ensure its well running. PLC equipped with ultra high pressure alarm to protect metering pump and material tube in material system from damage. Also withting of temperature upper and low limits to insure materials’ normal operation under stable temperature. Temperature error of ± 2 ℃.

|

序 号 No. |

项 目 Item |

技 术 参 数 Technical Parameter |

|

1 |

注射压力 Injection Pressure |

0.1-0.6Mpa |

|

2 |

注射流量 Injection flow rate |

50-130g/s 3-8Kg/min |

|

3 |

混合比范围 Mixing ratio range |

100:6-18(adjustable) |

|

4 |

注射时间 Injection time |

0.5~99.99S(精确到0.01S) 0.5~99.99S (correct to 0.01S) |

|

5 |

料温控制误差 Temperature control error |

±2℃ |

|

6 |

重复注射精度 Repeated injection precision |

±1% |

|

7 |

混合头mixing head |

约5000转/分钟 、强制动态混合 Around 5000rpm (4600~6200rpm,adjustable), forced dynamic mixing |

|

8 |

料罐容积Tank volume |

220L/30L |

|

A maximum working temperature |

70~110℃ |

|

|

B maximum working temperature |

110~130℃ |

|

|

9 |

清洗罐 Cleaning tank |

20L 304# stainless steel |

|

10 |

计量泵Metering pump |

JR50/JR50/JR9 |

|

A1 A2 Metering pump displacement |

50CC/r |

|

|

B Metering pump displacement |

6CC/r |

|

|

A1-A2-B-C1-C2 PUMPS MAXIMUM SPEED |

150RPM |

|

|

A1 A2 agitator speed |

23RPM |

|

|

11 |

压缩空气需要量 compressed air requirement |

干燥、无油 dry, oil free P:0.6-0.8MPa Q:600L/min(Customer-owned) |

|

12 |

真空需要量 Vacuum requirement |

P:6X10-2Pa(6 BAR) 抽气速率speed of exhaust:15L/S |

|

13 |

温控系统 Temperature control system |

加热:18~24KW Heating: 18~24KW |

|

14 |

输入电源 Input power |

三相五线 three-phrase five-wire,380V 50HZ |

|

15 |

加热功率Heating power |

TANK A1/A2: 4.6KW TANK B: 7.2KW

|

|

16 |

Total power |

34KW |

Polyurethane products are used in a wide variety of applications and industries. While a large part of our focus is on bulk material handling, concrete and agriculture, we can do so much more.

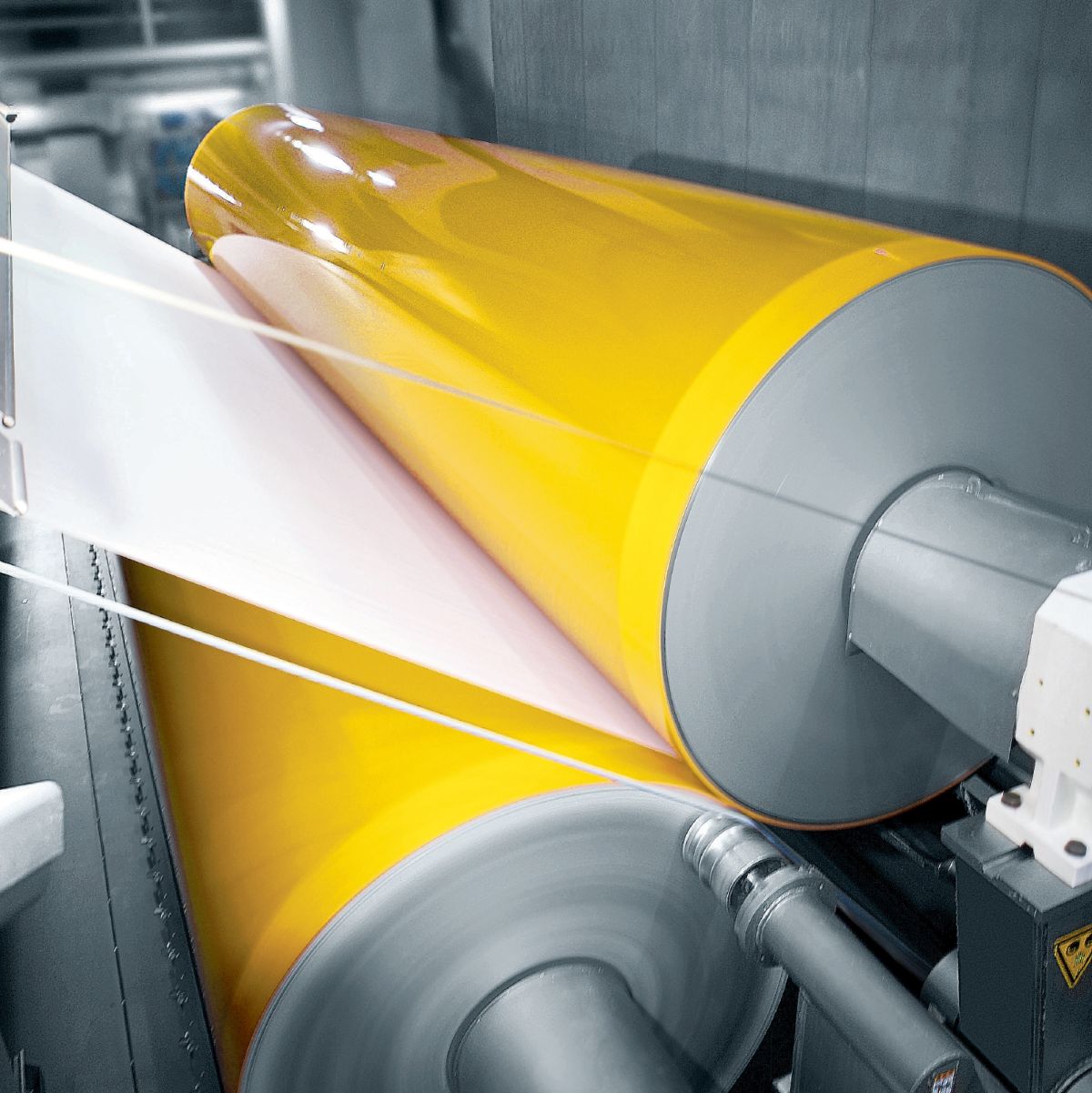

Other industries that we have had success in are microelectronics and photovoltaic industries, where our wire-cutting rollers are used in the creation of silicon waters for processing silicon chips. Our rollers help guide diamond-coated wires to cut the silicon material.

Urethane Wire Guide Rollers Coating Elastomer Casting Machine for wire saw machines in the process of diamond wire cutting (mono/multi silicon blocks into wafers)