Motorcycle Seat Bike Seat Making Machine High Pressure Foaming Machine

Feature

High pressure foaming machine is used for automobile interior decoration, exterior wall thermal insulation coating, thermal insulation pipe manufacturing, bicycle and motorcycle seat cushion sponge processing. High pressure foaming machine has excellent thermal insulation performance, even better than polystyrene board. High pressure foaming machine is a special equipment for filling and foaming of polyurethane foam. The high-pressure foaming machine is suitable for the processing of automobile interior, bicycle and motorcycle seat sponges, and also for the manufacture of thermal insulation pipes.

1) The bicycle saddle foaming machine matched with the disc has the function of continuous automatic material injection, free of manual operation and solvent-free cleaning, and has extremely high production efficiency.

2) The mixing head is light and dexterous, the structure is special and durable, the material is synchronously discharged, the stirring is uniform, and the nozzle will never be blocked.

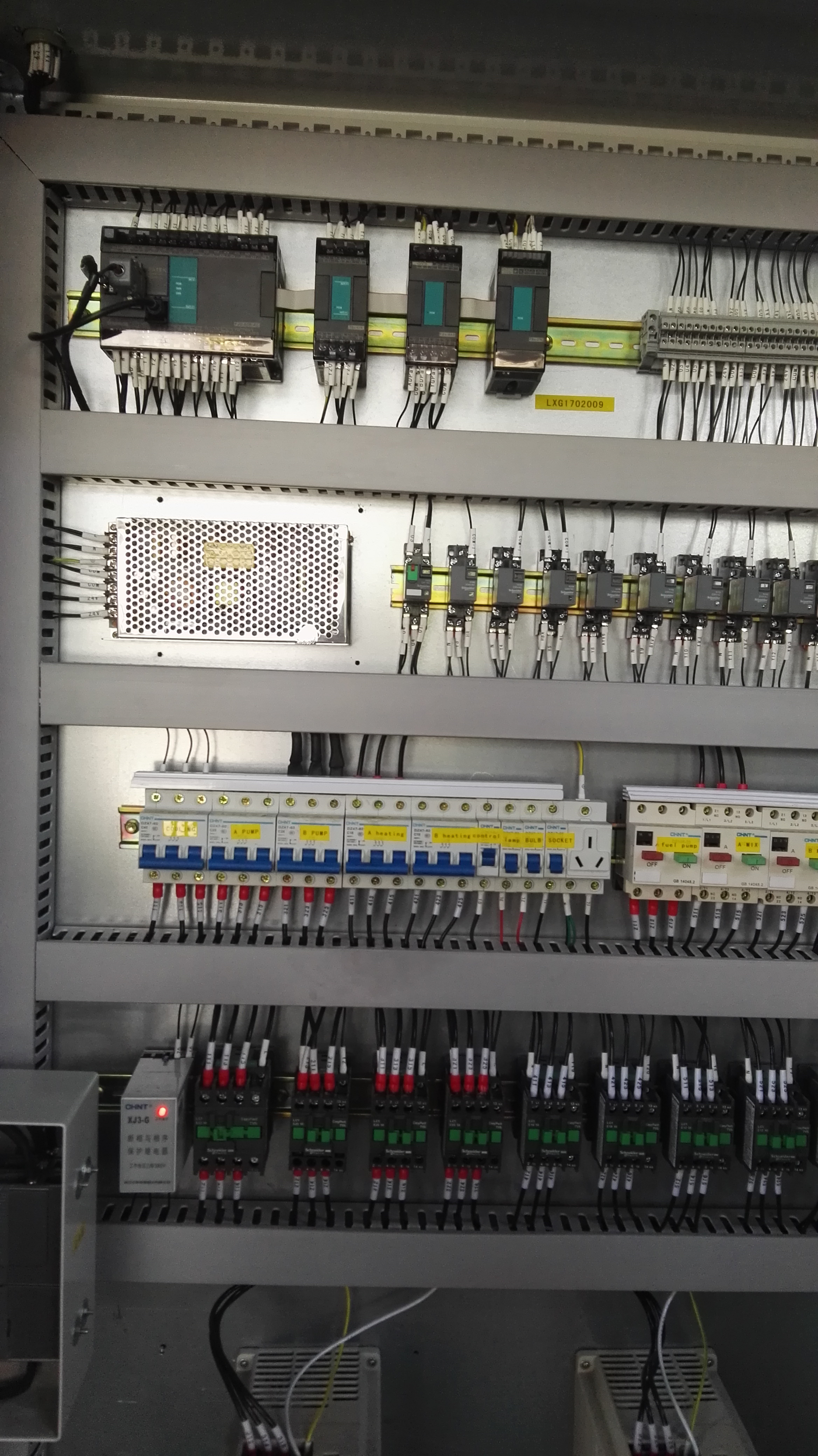

3) Microcomputer system control, with humanized automatic cleaning function, high timing accuracy.

4) The metering system adopts high-precision metering pump, which has high metering accuracy and is durable.

Operation Precautions

1. Non-staff (non-training personnel) do not operate blindly.

2. The new equipment needs to be energized and ventilated, and the material injection operation should be carried out after the inspection.

3. Industrial ventilation and exhaust devices should be installed in the equipment placement room.

4. Flammable materials need to be isolated from the equipment and equipped with fire-fighting facilities.

5. Note: If the machine is shut down for a long time, it is necessary to clean and seal the black material module to avoid curing and cause the metering pump to fail to operate normally.

6. When personnel operate the equipment, please do a good job of protection, respiratory tract, face, hands, etc.

|

Item |

Technical Parameter |

|

Foam application |

PU(Polyurethane) |

|

Raw material viscosity(22℃) |

POL~2500mPas ISO ~1000mPas |

|

Injection pressure |

10~20Mpa (adjustable) |

|

Injection Output (mixing ratio 1:1) |

70-350g/s |

|

Mixing ratio range |

1:3~3:1(adjustable) |

|

njection time |

0.5~99.99S(correct to 0.01S) |

|

Material temperature control error |

±2℃ |

|

Repeated injection accuracy |

±1% |

|

Mixing head |

Homemade, four oil hoses, double oil cylinders |

|

Hydraulic system |

Output 10L/min System pressure 10~20MPa |

|

Tank volume |

280L |

|

POL metering pump |

Guoyou A2VK-12 |

|

ISO metering pump |

Guoyou A2VK-06 |

|

Compressed air required |

Dry, oil free P: 0.7Mpa Q: 600NL/min Prepare by Customer |

|

Temperature control system |

5HP |

|

Input power |

Three-phase five-wire,380V 50HZ |

Suitable for high rebound, slow rebound, PU self-skinning, hard material foaming, bicycle saddle foaming, etc.