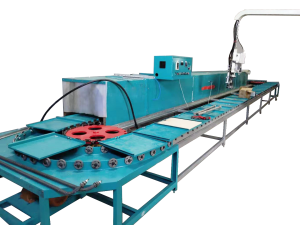

JYYJ-HN35L Polyurea Vertical Hydraulic Spraying Machine

1.The rear-mounted dust cover and the decorative cover on both sides are perfectly combined, which is anti-dropping, dust-proof and ornamental

2. The main heating power of the equipment is high, and the pipeline is equipped with built-in copper mesh heating with fast heat conduction and uniformity, which fully demonstrates the material properties and work in cold areas.

3.The design of the whole machine is simple and user-friendly, the operation is more convenient, quick and easy to understand, and the failure rate is low.

4. The smart and advanced electromagnetic commutation method is adopted to ensure the stable spraying of the equipment and the continuous atomization of the spray gun.

5.Equipped with real-time voltage detection LCD display window, you can observe the power input status at any time.

6. The heating system adopts the self-tuning PiD temperature control system, which automatically adapts to the temperature difference setting, and cooperates with the perfect temperature measurement and over-temperature system to ensure the precise control of material temperature.

7. The proportional pump barrel and the lifting piston are made of high wear-resistant and high-strength materials, which can reduce the wear of seals and prolong the service mission.

8. The feeding system adopts the new T5 pump with large flow rate and no barrel seal, which makes feeding easy and worry-free

9. The booster is driven by hydraulic pressure, the output pressure of raw materials is more stable and strong, and the work efficiency is increased.

| Model | JYYJ-HN35L |

| Medium Raw Material | Polyurea (Polyurethane) |

| Maximum Fluid Temperature | 90℃ |

| Maximum Output | 9kg/min |

| Maximum Working Pressure | 25Mpa |

| heating power | 17kw |

| Hose Maximum Length | 90m |

| Power Parameters | 380V-50A |

| drive Mode | Vertical Hydraulic |

| Volume Parameter | 930*860*1290 |

| Package Dimensions | 1020*1000*1220 |

| Net Weight | 185kg |

| Package Weight | 220kg |

| Host | 1 |

| Feed Pump | 1 |

| Spray Gun | 1 |

| Heating Insulation Pipe | 15m |

| Side Tube | 1 |

| Feed Tube | 2 |

Chemical storage tank anticorrosion, pipeline anticorrosion, demineralized water tank, wear-resistant lining, hull anticorrosion and thermal insulation, buoyant material application, subway, tunnel, paradise, industrial floor, waterproof engineering, sports engineering, hydropower engineering, thermal insulation engineering, etc.