JYYJ-H600D Polyurethane Foam Spraying Machine

Feature

1. Hydraulic drive, high working efficiency, stronger power and more stable;

2. The air-cooled circulation system reduces the oil temperature, protects the main engine motor and the pressure regulating pump, and the air-cooled device saves oil;

3. A new booster pump is added to the hydraulic station, and the two raw material booster pumps act at the same time, and the pressure is stable;

4. The main frame of the equipment is welded and sprayed with seamless steel pipes, which makes the equipment lighter in weight, higher in pressure and stronger in corrosion resistance.

5. Equipped with an emergency switch system, which can respond to emergencies;

6. The reliable and powerful 380V heating system can quickly heat up the raw materials to the ideal state, which can meet the normal construction of the equipment in cold areas.

7. The user-friendly setting of the equipment operation panel makes it easy to master the operation method;

8. The new spray gun has the advantages of small size, light weight and low failure rate;

9. The feeding pump adopts a large variable ratio method, which can also be easily supplied when the viscosity of the raw material is high in winter;

10. Specially developed and designed for large area and continuous spraying of polyurea elastomer.

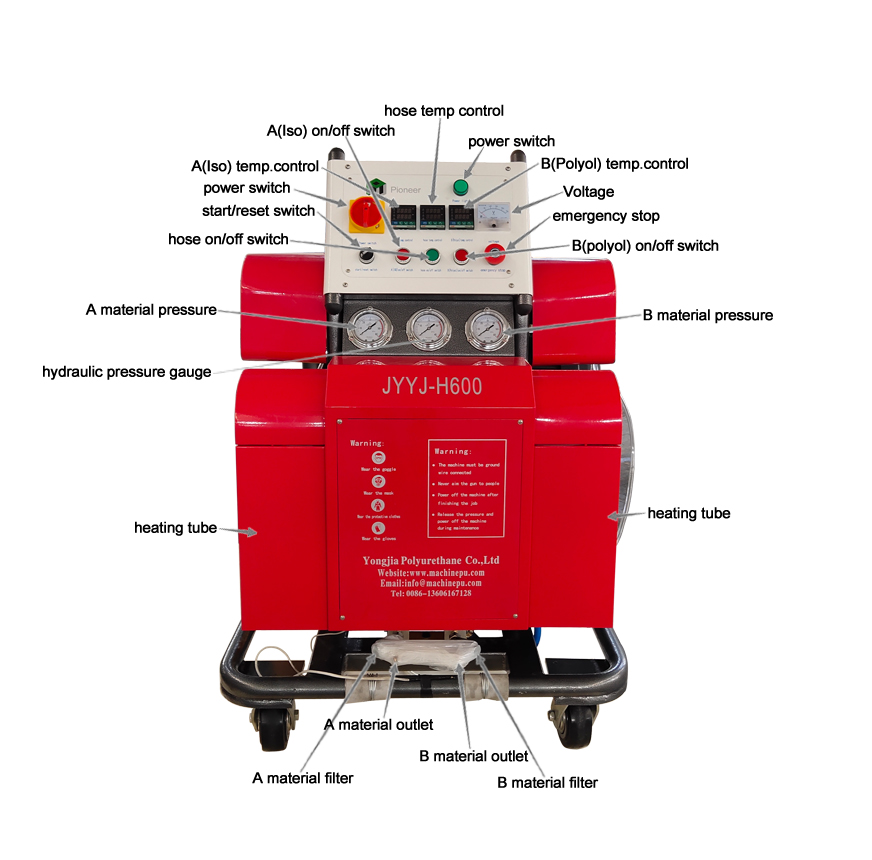

Temperature control table: setting and displaying real-time system temperature;

Thermostat switch: Controlling on-and-off of the heating system. When it’s on, the system temperature will cut off the power automatically after the temperature reaches the setting, the light is off at the moment; When the temperature is below the setting, it will activate heating system automatically, the light is on at the moment; If heating is no longer needed, you can manually turn off the switch, the light is off at the moment.

Start / Reset switch: When you start the machine, making the knob pointing at Start. When the work is done, switching it to the reset direction.

Hydraulic pressure indicator: Displaying the output pressure of A/B material when the machine is working

Raw material outlet: Outlet of A/B materials and are connected with A/B material pipes;

Main power: Power switch to turn on and off of the equipment

A/B material filter: filtering impurities of A/B material in the equipment;

Heating tube: heating A/B materials and is controlled by Iso/polyol material temp. control

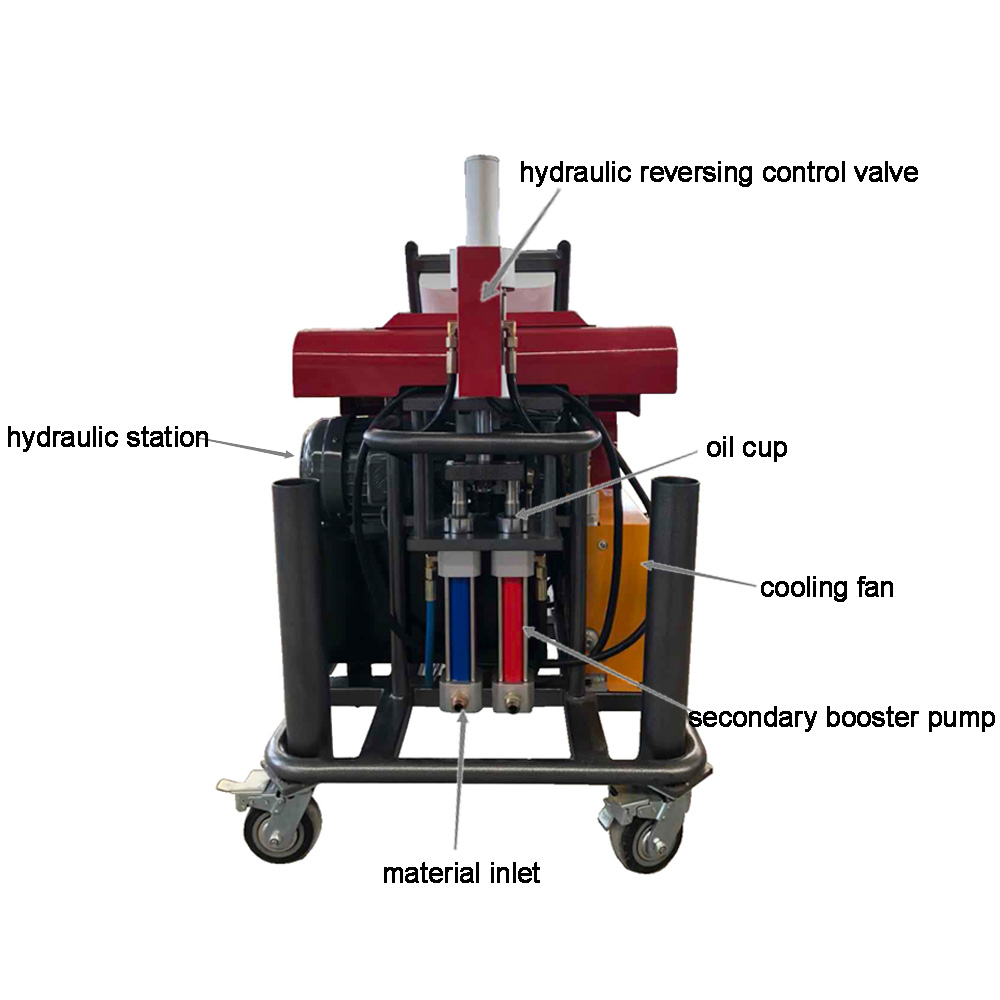

Hydraulic station oil-adding hole:When the oil level in oil feed pump is getting low, open the oil-adding hole and add some oil;

Emergency switch: Cutting off power rapidly in emergencies;

Booster pump: booster pump for A, B material;

Voltage: displaying voltage input;

Hydraulic fan:air cooling system to reduce oil temperature, saving oil as well as protect motor and pressure adjuster;

Oil gauge :Indicate the oil level inside the oil tank;

Hydraulic station reversing valve: control the automatic reverse for hydraulic station

| Voltage | 380V 50HZ |

| Heating Power | 23.5KW/19.5kw |

| OUTPUT | 2-12kg/Min |

| Pressure | 6-18Mpa |

| Max Outptu (Mpa) | 36Mpa |

| Matrial A:B= | 1:1 |

| Spray Gun:(set) | 1 |

| Feeding Pump | 2 |

| Barrel Connector | 2 sets heating |

| Heat Hose:(m) | 7/set |

| Gun Connector | 2*1.5m |

| Accessories Box: | 1 |

| Instruction Manuel | 1 |

| Weight | 356kg |

| Packaging | wooden box |

| Package size(mm) | 1220*1050*1 530 |

1. For Spray:

Desalting Water Tanks, Water Parks, Sports Stands, High-Speed Rail, Viaducts,Industrial & Mining, Equipments, Foam Sculptures, Valve Workshop Flooring, Bulletproof Clothing, Armored Vehicles, Sewage Tanks, Exterior Walls, etc.

2. Fo Casting:

Slab Lifting, Foundation Repair, Foundation Raise, Slab Raise, Concrete Repair, Indoor Door, Anti-Theft Door, Floor Heating Plate, Electric Heating Plate, Broken Bridge, Aluminum Profile, Pipe Joint, Water Heater, Water Tank, Beer Tank, Storage Tank, Cold and Hot Water Pipe, Pipe Joint Repair, Packing, Thermos Cup,etc.