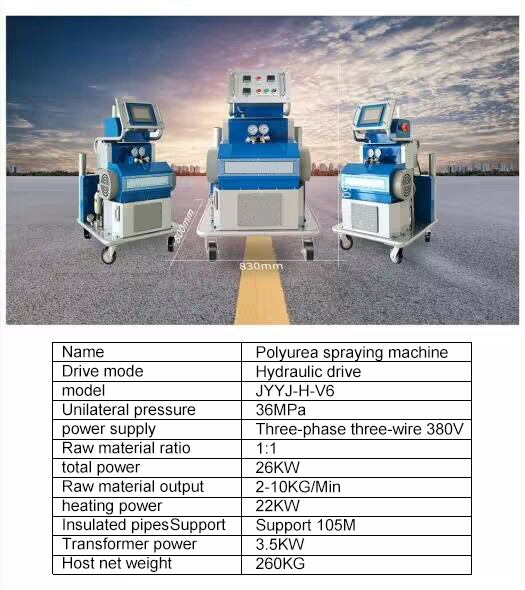

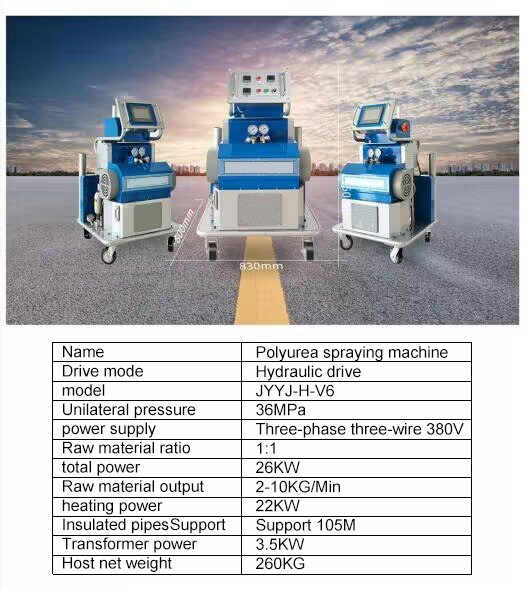

JYYJ-H-V6 Polyurethane Spray Foam Machine Injection Molding Hydraulic Polyurea Spraying Machine

The technologically advanced and highly efficient Polyurethane Spray Machine is your ideal choice for enhancing coating quality and work efficiency. Let’s explore its remarkable features together:

- High Precision Coating: The Polyurethane Spray Machine achieves highly precise coating through its outstanding spray technology, ensuring each application meets the highest standards.

- Intelligent Control System: Equipped with an advanced intelligent control system, the device features a user-friendly interface that makes parameter adjustments easy, enhancing operational convenience.

- Versatile Applicability: Whether it’s adhesive, paint, or other liquid materials, the Polyurethane Spray Machine demonstrates exceptional versatility, meeting the coating requirements of various projects.

- Compact Structural Design: The equipment adopts a compact structural design, powerful yet occupying minimal space, providing an ideal solution for limited workspaces.

- Building Insulation: In the construction sector, the Polyurethane Spray Machine is used to provide efficient insulation coatings for walls and roofs, improving the energy efficiency of buildings.

- Automotive Coating: Applied to the surface of automobiles, ensuring durable and uniform coatings, enhancing the appearance and corrosion resistance of vehicles.

- Furniture Manufacturing: Suitable for coating wood and furniture surfaces, imparting durability and aesthetic appeal to products.

- Industrial Coating: For large-scale industrial projects, the Polyurethane Spray Machine offers efficient and precise coating, meeting diverse coating needs.

- Aerospace Applications: Employed in aerospace manufacturing for bonding, sealing, and coating composite materials to meet performance requirements in extreme environments.

Write your message here and send it to us