JYYJ-3H Polyurethane Spray Foam Machine PU Spray Equipment

1. Pneumatic booster device: It has the advantages of light weight, small size, low failure rate, simple operation, convenient movement, and safety. It can provide enough working pressure during operation.

2. Advanced ventilation system: smooth ventilation mode, which can ensure the stability of the equipment during operation.

3. Raw material filtering device: multiple raw material filtering devices can reduce the problem of spraying clogging and ensure smooth use.

4. Safety system: Multiple leakage protection systems can protect the safety of operators. Equipped with an emergency switch system, it can quickly respond to emergencies.

5. Precautions when using equipment: protective face shield, splash goggles, chemical protective clothing, protective gloves, protective shoes

Air pressure regulator: adjusting highs and lows of input air pressure

Barometer: displaying input air pressure

Oil-water separator: providing lubricating oil for the cylinder

Air-water separator: filtering the air and water in the cylinder

Power light: showing if there’s voltage input, light on, power on; light off, power off

Voltmeter: displaying voltage input

Temperature control table: Setting and displaying real-time system temperature

Thermostat switch: Controlling on-and-off of the heating system. When it’s on, the system temperature will cut off the power automatically after the temperature reaches the setting, the light is off at the moment; When the temperature is below the setting, it will activate heating system automatically, the light is on at the moment; If heating is no longer needed, you can manually turn off the switch, the light is off at the moment.

Start / Reset switch: When starting the machine, switching the button to Start. When the work is done, switching it to the reset direction.

Hydraulic pressure indicator: Displaying the output pressure of Iso and polyol material when the machine is working

Emergency switch: Cutting off power rapidly in emergencies

Raw material outlet: Outlet of Iso and polyol materials and are connected with Iso and polyol material pipes

Main power: Power switch to turn on and off of the equipment

Iso/polyol material filter: filtering impurities of Iso and polyol material in the equipment

Heating tube: heating Iso and polyol materials and is controlled by Iso/polyol material temp.

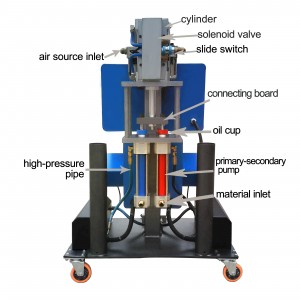

Air source input: connecting with air compressor

Slide switch: Controlling input and on-and-off of the air source

Cylinder: booster pump power source

Power Input : AC 220V 60HZ

Primary-Secondary pumping system: booster pump for A, B material;

Raw material inlet : Connecting to feeding pump outlet

Solenoid valve(electromagnetic valve): Controlling reciprocating motions of cylinder

| Power source | single phase 380V 50HZ |

| Heating power | 9.5KW |

| Driven mode: | pneumatic |

| Air source | 0.5~0.8 MPa ≥0.9m³/min |

| Raw output | 2~10 kg/min |

| Maximum output pressure | 25 Mpa |

| AB material output ratio | 1:1 |

Insulation spraying: Insulation spraying for interior walls, roofs, cold storage, cabins, carriages, tanks, carriages, refrigerated vehicles, etc.;

Casting: solar water heaters, thermal insulation water tanks, cabins, thermal insulation panels, security doors, refrigerators, pipelines, product packaging, road construction, mold filling, wall sound insulation, etc.;