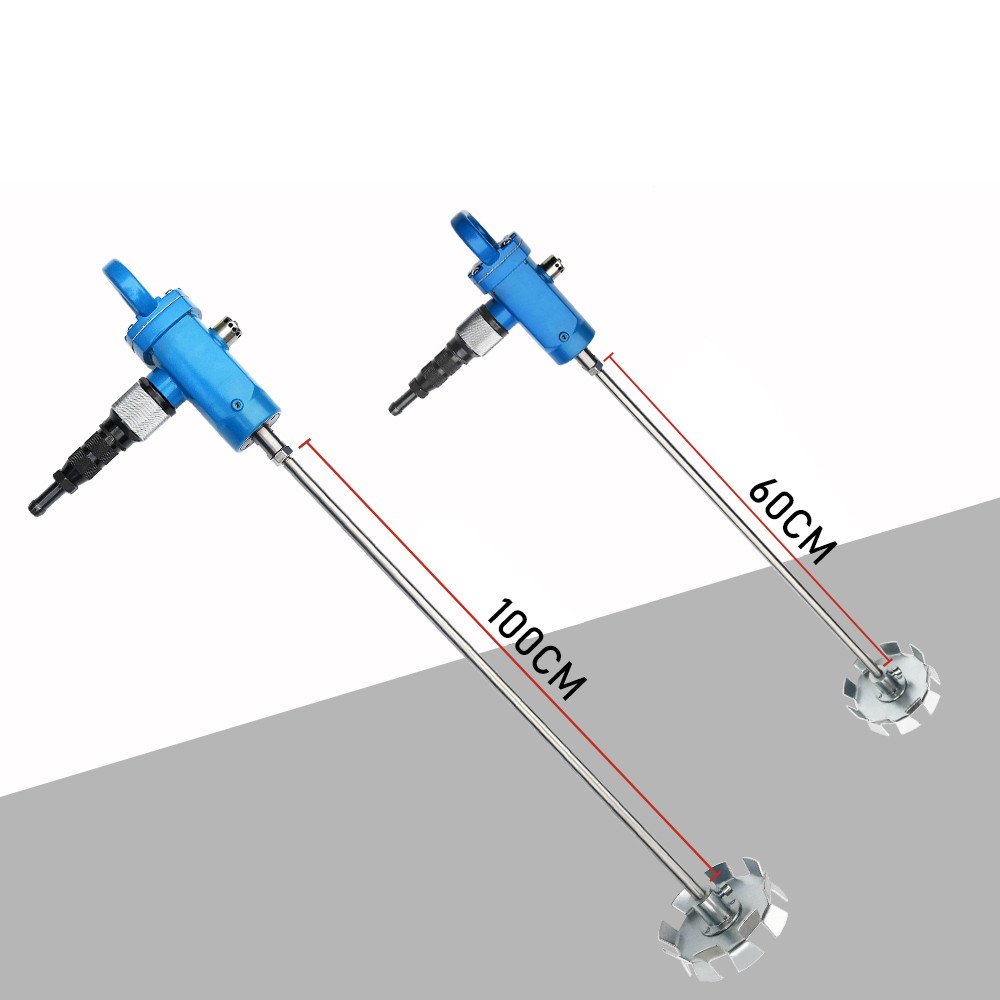

Industrial Mixer Paint Paint Mix Cement Putty Powder Concrete Ash Machine Mixer

Feature

Product Description: We are proud to introduce our Industrial Raw Material Paint Pneumatic Handheld Mixer, a high-efficiency mixing solution designed specifically for industrial production environments. This mixer utilizes advanced pneumatic technology, offering powerful mixing capabilities and stability for blending various raw material paints, coatings, and adhesives. Its compact handheld design ensures convenient operation while providing precise mixing control to ensure quality and 必利勁

efficiency throughout the production process.

- Efficient Mixing Capability: Powered by a robust pneumatic drive system, it swiftly and evenly blends raw material paints, enhancing production efficiency.

- Stability and Precision: Carefully engineered structure and control system maintain stability during operation, providing accurate mixing control to prevent overmixing or undermixing.

- Durable Materials: Constructed with corrosion-resistant and wear-resistant materials, this mixer withstands challenging industrial environments.

- Convenient Operation: The handheld design offers flexibility and ease of use, allowing operators to carry and utilize it across different workstations.

- Safety: Equipped with safety measures to ensure secure operation and prevent accidents.

| Power: | 0.80KW |

| Free Speed: | ≤2500RPN |

| Stirring rod length: | 60cm |

| Diameter of impeller: | 11cm |

| Torque: | 2.6N.m |

| Air Consumption: | 0.22m³/min |

| Weight: | 3kg |

- Automotive Manufacturing: Mixing automotive paints, primers, and clear coats to ensure painting quality and aesthetic appeal.

- Metal Fabrication: Blending metal coatings and corrosion-resistant paints for material protection and decoration.

- Furniture Production: Mixing wood coatings and paints for smooth and uniform furniture surface finishes.

- Construction: Blending construction paints, adhesives, and sealants for durable and aesthetically pleasing buildings.

- Chemical Production: Mixing various chemical raw materials for producing pigments, resins, and coatings.

Write your message here and send it to us