PUR PU Polyurethane Ua Npuas Ncauj Filling Tshuab Rau 3D Phab Ntsa Vaj Huam Sib Luag Ua

Polyurethanetshuab foaming, muaj kev lag luam, kev lag luam yooj yim thiab kev saib xyuas, thiab lwm yam, tuaj yeem kho raws li cov neeg siv khoom thov ntau yam dej tawm ntawm lub tshuab.

Qhov nopolyurethane tshuab foamingsiv ob raw khoom, polyurethane thiab Isocyanate.Hom PU noua npuas ncauj tshuabtuaj yeem siv rau ntau yam kev lag luam, xws li khoom siv niaj hnub, tshebkho kom zoo nkauj, cov khoom siv kho mob, kev lag luam kis las, khau tawv, kev lag luam ntim khoom, rooj tog kev lag luam, kev lag luam tub rog.

Khoom nta ntawm High Pressure PU Tshuab:

1.Adopting peb txheej cia tank, stainless hlau liner, sandwich hom cua sov, txheej qhwv nrog rwb thaiv tsev txheej, kub adjustable, nyab xeeb thiab txuag zog;

2.Ntxiv cov khoom siv coj mus kuaj system, uas tuaj yeem hloov pauv yam tsis muaj kev cuam tshuam rau kev tsim khoom, txuag sijhawm thiab khoom siv;

3. Tsawg ceev high precision metering twj tso kua mis, qhov tseeb piv, random yuam kev hauv ± 0.5%;

4.Material flow rate thiab presure adjusted by converter motor with variable zaus tswj, siab raug, yooj yim thiab ceev ration adjusting;

5.High-kev ua tau zoo sib xyaw ntaus ntawv, raug synchronous cov ntaub ntawv tso zis, txawm sib tov.Tshiab leakproof qauv, dej txias lub voj voog sib txuas tshwj xeeb kom tsis txhob muaj qhov thaiv thaum lub sij hawm poob ntev;

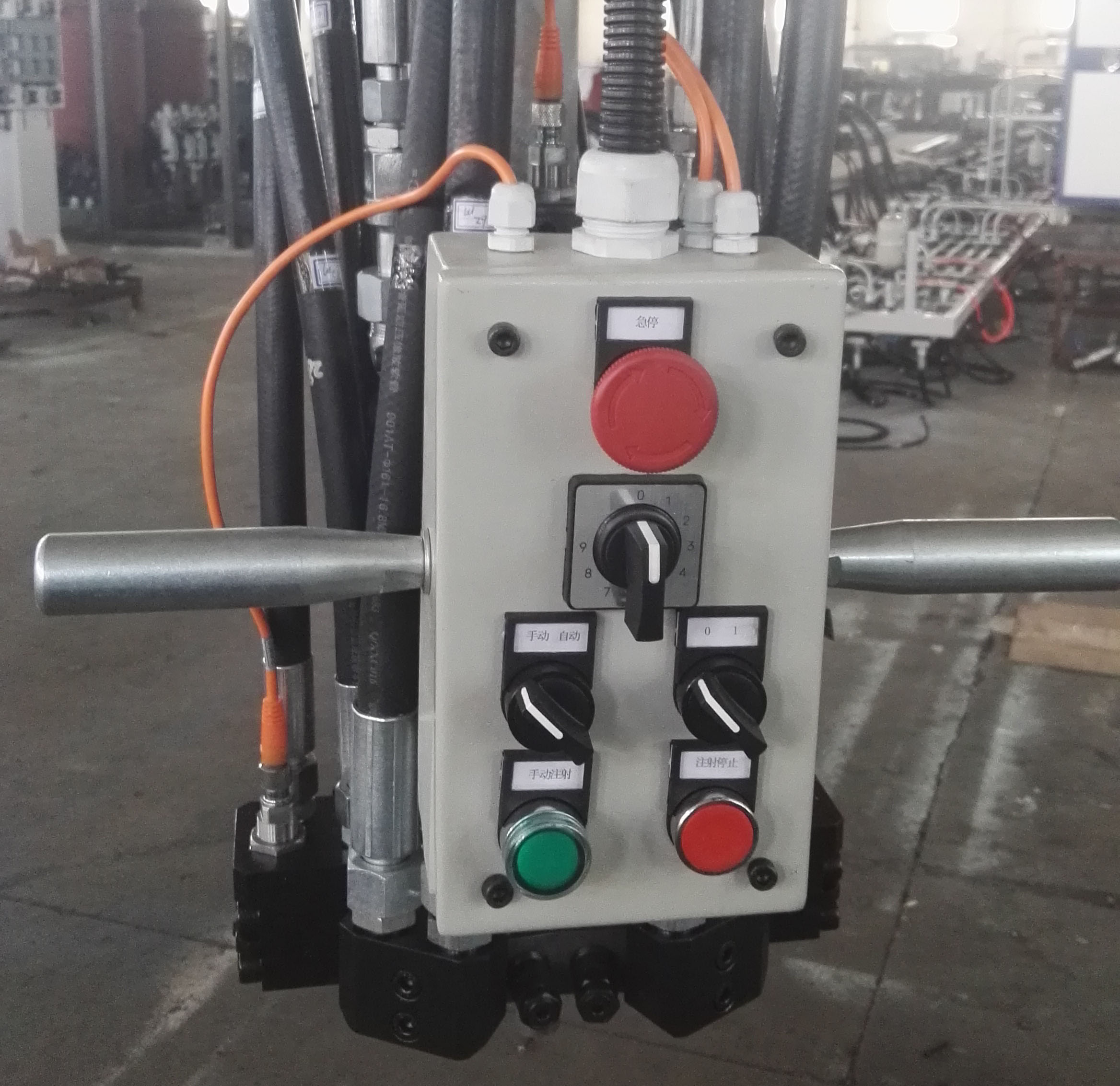

6.Adopting PLC thiab kov lub vijtsam txiv neej-tshuab interface los tswj kev txhaj tshuaj, tsis siv neeg tu thiab cua ntws tawm, kev ua haujlwm ruaj khov, kev ua haujlwm siab, txiav qhov txawv, kuaj xyuas thiab lub tswb qhov teeb meem txawv txav, tso saib cov yam ntxwv txawv txav.

Cov khoom siv tank: Poly / Iso tank nrog 500L, thermostatic tswj los ntawm ob txheej phab ntsa nrog rwb thaiv tsev txheej, txhim kho ob phau ntawv nres li qub hauv qhov hluav taws xob xa khoom, hauv qab nruab nrog cov khib nyiab.

Lub taub hau sib xyaw: Txais L hom tsis siv neeg ntxuav nws tus kheej lub taub hau, rab koob hom nozzle adjustable, V hom dav hlau orifice, High-pressure collisional mixing txoj cai kom nws cov nyhuv.

Chiller: Siv los muab cov dej txias rau chav txias, lub tub yees muaj peev xwm 38700Kcal / h; (kev xaiv)

| Tsis muaj. | Yam khoom | Technical parameter |

| 1 | Ua npuas ncauj thov | Ua Npuas Ncauj |

| 2 | Raw khoom viscosity (22 ℃) | POLY ~ 2500MPas ISO ~1000MPas |

| 3 | Txhaj tshuaj | 10-20Mpa (kho tau) |

| 4 | Cov zis (sib piv 1: 1) | 280-1300g / min |

| 5 | Mixing ratio ntau | 1: 5 ~ 5: 1 (kho tau) |

| 6 | Lub sijhawm txhaj tshuaj | 0.5 ~ 99.99S (yog rau 0.01S) |

| 7 | Khoom siv kub tswj yuam kev | ± 2 ℃ |

| 8 | Rov ua qhov tseeb txhaj tshuaj | ± 1% |

| 9 | Muab lub taub hau | Plaub lub tsev roj, ob lub tog raj kheej roj |

| 10 | Hydraulic system | Cov zis: 10L / min Qhov system siab 10 ~ 20MPa |

| 11 | Tank ntim | 500L |

| 15 | Kub tswj qhov system | Lub Zog: 2 × 9Kw |

| 16 | Input zog | Peb-theem tsib-xaim 380V |

Piv nrog rau lwm cov phab ntsa tom qab, cov mos 3D PU tom qab phab ntsa muaj qhov muag zoo nkauj heev thiab cov xim mos, uas tuaj yeem ua kom zoo rau txhua qhov chaw nyob hauv ib puag ncig zoo nkauj.Vim qhov tshwj xeeb craftsmanship ntawm cov mos-them tom qab phab ntsa, nrog rau cov yam ntxwv thiab khoom kim heev ntawm cov khoom siv, nws tau zoo heev txhim kho qib ntawm tag nrho cov tsev.Tsis tas li ntawd, qhov kev nkag siab ntawm peb sab ntawm cov phab ntsa mos-nplaum tom qab kuj tuaj yeem txhim kho qib ntawm qhov chaw hauv tsev..Ntxiv nrog rau kev ua kom zoo nkauj ntawm qhov chaw, cov phab ntsa muag muag tom qab muaj cov haujlwm ntawm lub suab nqus, suab rwb thaiv tsev, tiv thaiv kev sib tsoo, kev poob siab, hluav taws kub thiab nplaim hluav taws.Cov phab ntsa tom qab muag tsis yog tsuas yog zoo nkauj xwb tab sis kuj siv tau heev.