PU khau Insole Pwm

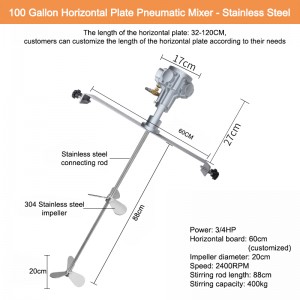

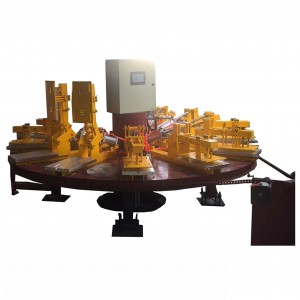

Kev Txhaj Tshuaj Mould:

1.ISO 2000 tau ntawv pov thawj.

2. ib qho kev daws teeb meem

3.mould lub neej, 1 lab txhaj tshuaj

Peb Cov Pwm Zoo Zoo:

1) ISO9001 ts16949 thiab ISO14001 ENTERPRISE, ERP tswj qhov system

2) Tshaj 16 xyoo nyob rau hauv precision yas pwm tsim, sau cov kev paub nplua nuj

3) Kev ruaj khov pab pawg thiab kev cob qhia tsis tu ncua, cov neeg tswj hwm nruab nrab txhua tus ua haujlwm rau ntau tshaj 10 xyoo hauv peb lub khw

4) Cov cuab yeej sib xws, CNC chaw los ntawm Sweden, Daim iav EDM thiab JAPAN precision WIRECUT

Peb cov kws tshaj lij ib-nres yas pwm kev pabcuam kev pabcuam:

1) Pwm tsim kev pab cuam thiab duab tsim tshwj xeeb rau peb cov neeg siv khoom

2) Yas txhaj pwm ua, ob txhaj tshuaj pwm, roj pab pwm

3) Precision yas molding: ob txhaj molding, precision yas molding thiab roj pab molding

4) Yas Secondary lag luam, zoo li Silk-screening, UV, PU painting, Kub stamping, Laser engraving, Ultrasonic vuam, Plating thiab lwm yam.

Pwm nrog pp yas uas txhais tau tias lub insole tuaj yeem yooj yim demoulded yam tsis muaj tshuaj tsuag lwm tus neeg tso tawm.

| Pwm Hom | Yas txhaj mould, overmolding, Interchangeable Pwm, ntxig molding, compression pwm, stamping, tuag casting pwm, thiab lwm yam |

| Cov kev pabcuam tseem ceeb | Pwm tsim, Pwm tsim, Pwm kuaj,tsawg ntim / siab ntim yas ntau lawm |

| Cov khoom siv hlau | 718H, P20, NAK80, S316H, SKD61, thiab lwm yam. |

| Yas ntau lawm Raw khoom | PP, PU, Pa6, PLA, AS, ABS, PE, PC, POM, PVC, Resin, PET, PS, TPE / TPR thiab lwm yam |

| Pwm puag | HASCO, DME, LKM, JLS tus qauv |

| Pwm khiav | Kub khiav, kub khiav |

| Pwm kub khiav | DME, HASCO, YUDO, thiab lwm yam |

| Pwm txias khiav | taw tes txoj kev, sab txoj kev, ua raws txoj kev, ncaj rooj vag txoj kev, thiab lwm yam. |

| Pwm strandard qhov chaw | DME, HASCO, thiab lwm yam. |

| pwm lub neej | > 300,000 txhaj tshuaj |

| Pwm kub kho | quencher, nitridation, tempering, thiab lwm yam. |

| Pwm cua txias system | dej txias lossis Beryllium bronze txias, thiab lwm yam. |

| Pwm nto | EDM, kev ntxhib los mos, siab gloss polishing |

| Hardness ntawm cov hlau | 20 ~ 60 HRC |

| Cov khoom siv | Kev kub ceev CNC, txheem CNC, EDM, Hlau txiav, grinder, tshuab dhos, Milling tshuab, yas txhaj tshuab |

| Lub Hlis Production | 100sets / hli |

| Pwm Ntim | txheem exporting Ntoo rooj plaub |

| Tsim software | UG, ProE, Auto CAD, Solidworks, thiab lwm yam. |

| Daim ntawv pov thawj | ISO 9001: 2008 Daim ntawv pov thawj |

| Lub sijhawm ua haujlwm | 25-30 hnub |

Kuv tsis paub muaj pes tsawg tus phooj ywg tau ntsib nrog PU insoles.Piv nrog rau cov tsoos insoles, pu insoles muaj ntau yam zoo.Ntau tus phooj ywg muaj kev sib txawv tom qab hloov mus rau PU insoles tshiab.Hnub no, kuv yuav tham nrog koj txog cov txiaj ntsig ntawm PU insoles.Qhov twg.

1. Kev ruaj ntseg: PU insoles yuav txhawb nqa los ntawm cov khoom siv roj hmab hauv qab ib nrab.Kev siv cov khoom siv no yuav muaj kev txhawb nqa zoo rau peb lub pob taws.Ib nkawm zoo insoles yuav txhawb pob taws zoo dua li cov khau zoo tib yam.Kev txhawb nqa yog qhov zoo dua, uas txhua tus tuaj yeem xav tias yog qhov tsis txaus ntseeg, tab sis qhov tseeb kuj ua pov thawj tias ib khub zoo ntawm insoles muaj qhov zoo li no.

2. Shock absorption: Txawm hais tias ntau lub khau muaj qhov ua haujlwm no, cov nyhuv ntawm insole nrog cov haujlwm no tsis tau nthuav tawm los ntawm ib qho ntxiv, thiab cov insole yog tag nrho haum rau ib leeg, yog li cov nyhuv shock absorber yuav zoo dua.

3. Kev Kho: Cov neeg feem coob tsis hnav khau zoo thaum lawv tseem hluas.Lub sijhawm no, Kenneng yuav muaj lub cev coj txawv txawv thaum taug kev, thiab qee qhov tseem muaj teeb meem xws li inversion, eversion, thiab tiaj tus taw.Nws yog ib qho yooj yim heev kom muaj insole phem Nws tuaj yeem ua teeb meem ntawm ko taw.Hauv cov xwm txheej hnyav, tej zaum yuav muaj teeb meem nrog pob taws thiab hauv caug pob qij txha, thiab tseem hnyav dua rau lub duav.Yog li ntawd, ib qho zoo insole yog ib qho tseem ceeb rau kev kho cov teeb meem ntawm ko taw.