PU Casting Tshuab Rau Polyurethane Mine Screen PU Elastomer Tshuab

1. Cov khoom siv tau txais kev ua haujlwm siab PLC tswj qhov system thiab 10.2-nti kov npo raws li cov khoom siv sab saud.Vim tias PLC muaj lub zog tshwj xeeb-tawm tuav ua haujlwm, tsis siv neeg kuaj xyuas muaj nuj nqi thiab tsis nco qab kev ua haujlwm.Siv cov cuab yeej tshwj xeeb cia, cov ntaub ntawv cuam tshuam ntawm kev teeb tsa thiab cov ntaub ntawv tuaj yeem khaws cia mus tas li, tshem tawm qhov tshwm sim ntawm cov ntaub ntawv poob los ntawm lub zog tsis ua haujlwm ntev.

2. Cov khoom siv ntawm nws tus kheej tsim ib qho kev tswj hwm tsis siv neeg raws li cov txheej txheem thev naus laus zis ntawm cov khoom, nrog kev ua haujlwm ruaj khov (tsis muaj kev sib tsoo, kev tsis sib haum xeeb, kev ua haujlwm poob, thiab lwm yam) thiab kev ua haujlwm siab automation.Cov cuab yeej siv kev tswj hwm qhov system kuj tuaj yeem kho raws li tus neeg siv khoom cov txheej txheem cov khoom, thiab cov khoom tseem ceeb ntawm kev tswj hwm tau lav rau ob xyoos.

3. Lub taub hau tshuab yog nruab nrog cov khoom siv rov qab, uas daws qhov teeb meem ntawm cov khoom siv thaum lub sij hawm nchuav.

4. Cov khoom siv prepolymer tank siv lub thawv tshwj xeeb nrog cov khoom siv zoo meej los daws qhov teeb meem ntawm kev cia khoom mus ntev thiab lub tshuab nqus tsev.

5. Lub MOC tivthaiv cua sov system txais kev pom thib ob los tiv thaiv cov roj carbonization ntawm cov roj hloov hluav taws xob thiab daws qhov teeb meem ntawm cov raj xa dej.

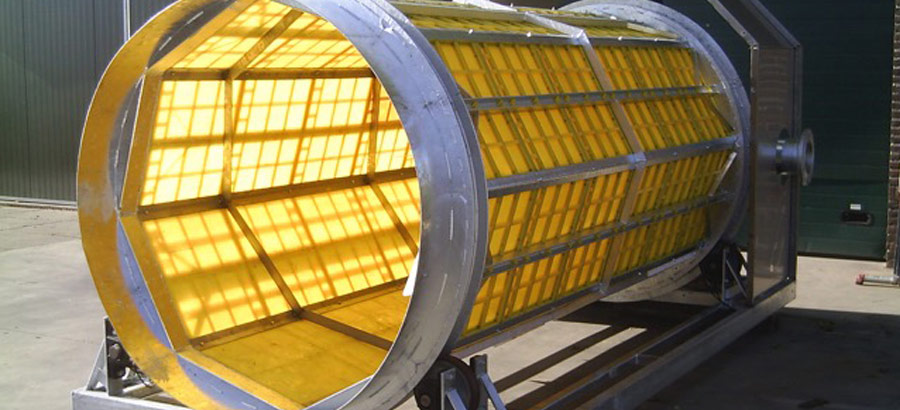

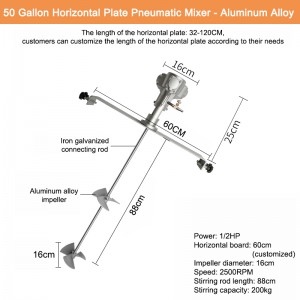

Tsis tankBuffer tank siv rau lub tshuab nqus tsev twj rau lim thiab twj Nqus siab accumulator.Lub tshuab nqus tsev twj tso kua mis rub tawm cua hauv lub tank los ntawm lub tank tsis, ua rau cov khoom siv cua txo qis thiab ua kom muaj npuas tsawg hauv cov khoom kawg. Ncuav lub taub hauTxais kev kub ceev txiav kiv cua V HOM sib tov lub taub hau (tsav hom: V siv), xyuas kom meej txawm tias sib tov nyob rau hauv qhov yuav tsum tau pouring tus nqi thiab sib tov sib piv.Lub cev muaj zog ceev tau nce los ntawm lub log synchronous ceev, ua rau lub taub hau sib hloov nrog kev kub ceev hauv kev sib xyaw cov kab noj hniav.A, B tov yog hloov mus rau lub xeev casting los ntawm lawv cov kev hloov pauv valve, tuaj rau hauv qhov sib xyaw champer los ntawm orifice.Thaum lub taub hau sib tov yog nyob rau hauv kev kub ceev kev sib hloov, nws yuav tsum tau nruab nrog txhim khu kev qha sealing ntaus ntawv kom tsis txhob pouring cov ntaub ntawv thiab xyuas kom meej qhov zoo ntawm cov kabmob.

Ncuav lub taub hauTxais kev kub ceev txiav kiv cua V HOM sib tov lub taub hau (tsav hom: V siv), xyuas kom meej txawm tias sib tov nyob rau hauv qhov yuav tsum tau pouring tus nqi thiab sib tov sib piv.Lub cev muaj zog ceev tau nce los ntawm lub log synchronous ceev, ua rau lub taub hau sib hloov nrog kev kub ceev hauv kev sib xyaw cov kab noj hniav.A, B tov yog hloov mus rau lub xeev casting los ntawm lawv cov kev hloov pauv valve, tuaj rau hauv qhov sib xyaw champer los ntawm orifice.Thaum lub taub hau sib tov yog nyob rau hauv kev kub ceev kev sib hloov, nws yuav tsum tau nruab nrog txhim khu kev qha sealing ntaus ntawv kom tsis txhob pouring cov ntaub ntawv thiab xyuas kom meej qhov zoo ntawm cov kabmob.

| Yam khoom | Technical Parameter |

| Txhaj Tshuaj | 0.1-0.6 Mpa |

| Txhaj tshuaj flow rate | 50-130g / s 3-8Kg / min |

| Mixing ratio ntau | 100:6-18(kho tau) |

| Lub sijhawm txhaj tshuaj | 0.5~99.99S (yog rau 0.01S) |

| Kev tswj qhov kub thiab txias | ± 2 ℃ |

| Rov txhaj tshuaj precision | ± 1% |

| Muab lub taub hau | Nyob ib ncig ntawm 5000rpm (4600 ~ 6200rpm, kho tau), yuam kev sib xyaw |

| Tank ntim | 220L / 30L |

| Qhov siab tshaj plaws ua haujlwm kub | 70 ~ 110 ℃ |

| B siab tshaj plaws ua haujlwm kub | 110 ~ 130 ℃ |

| Ntxuav lub tank | 20L 304 # stainless hlau |

| Compressed cua xav tau | qhuav, tsis muaj roj P:0.6-0.8MPa Q:600L / min(Cov neeg siv khoom) |

| Vacuum xav tau | P:6 X 10-2Pa (6 BAR) ceev ntawm tso pa tawm:15L / S |

| Kub tswj qhov system | Cua sov: 18~24 kWm |

| Input zog | peb kab lus tsib kab lus,380V 50Hz |

| Lub zog cua sov | Lub cev muaj zog A1 / A2: 4.6KW Lub cev muaj zog B: 7.2KW |