Polyurethane Ntoo Imitation Rigid Foam Duab Ncej Moulding Tshuab

Polyurethane foaming tshuab, muaj kev lag luam, kev lag luam yooj yim thiab txij nkawm, thiab lwm yam, tuaj yeem kho raws li tus neeg thov kev thov ntau yam dej tawm ntawm lub tshuab.

Qhov nopolyurethanefoaming tshuab siv ob raw khoom, polyurethane thiab Isocyanate.Hom PU ua npuas ncauj tshuab no tuaj yeem siv rau hauv ntau yam lag luam, xws li khoom siv niaj hnub, tshebkho kom zoo nkauj, cov khoom siv kho mob, kev lag luam kis las, khau tawv, kev lag luam ntim khoom, rooj tog kev lag luam, kev lag luam tub rog.

Khoom nta ntawm High Pressure PU Tshuab:

1.Adopting peb txheej cia tank, stainless hlau liner, sandwich hom cua sov, txheej qhwv nrog rwb thaiv tsev txheej, kub adjustable, nyab xeeb thiab txuag zog;

2.Ntxiv cov khoom siv coj mus kuaj system, uas tuaj yeem hloov pauv yam tsis muaj kev cuam tshuam rau kev tsim khoom, txuag sijhawm thiab khoom siv;

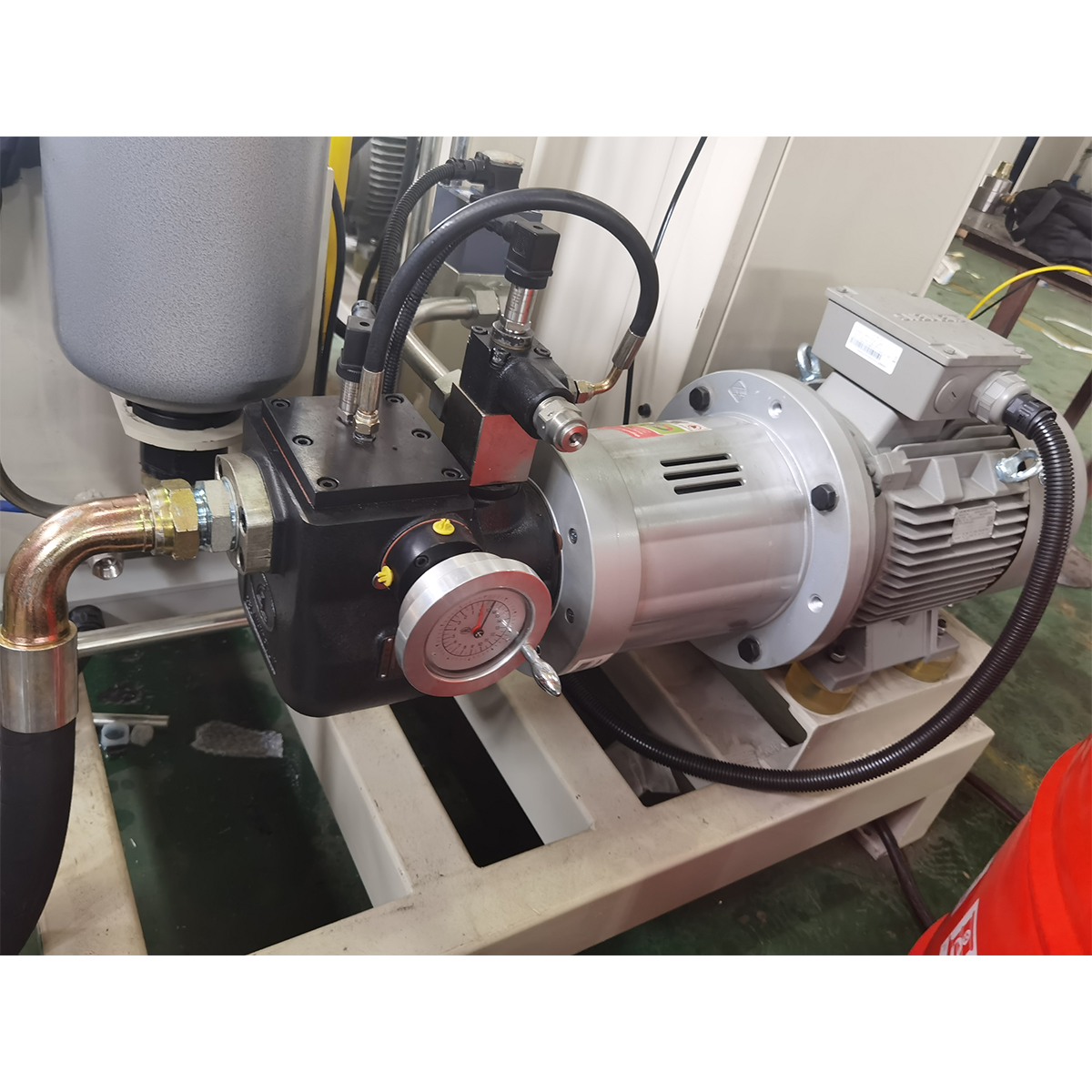

3. Tsawg ceev high precision meteringpump, qhov tseeb piv, random yuam kev hauv ± 0.5%;

4.Material flow rate thiab presure adjusted by converter motor with variable zaus tswj, siab raug, yooj yim thiab ceev ration adjusting;

5.High-kev ua tau zoo sib xyaw ntaus ntawv, raug synchronous cov ntaub ntawv tso zis, txawm sib tov.Tshiab leakproof qauv, dej txias lub voj voog sib txuas tshwj xeeb kom tsis txhob muaj qhov thaiv thaum lub sij hawm poob ntev;

6.Adopting PLC thiab kov lub vijtsam txiv neej-tshuab interface los tswj kev txhaj tshuaj, tsis siv neeg tu thiab cua ntws tawm, kev ua haujlwm ruaj khov, kev ua haujlwm siab, txiav qhov txawv, kuaj xyuas thiab lub tswb qhov teeb meem txawv txav, tso saib cov yam ntxwv txawv txav.

Ib txheej ntawm cov cuab yeej tswj kev kub siab, siv los kho thiab tswj kev ua haujlwm siab thiab teeb tsa lub siab ntawm 6MPa rau 22MPa, thaum lub siab dhau ntawm qhov ntau, cov khoom siv tsis raug ceeb toom thiab tso tawm cov lus yuam kev ntawm siab dua / qis dua.

Filter yog siv rau cov khoom siv lim dej, siv cov lim dej huv nws tus kheej, yog li kom tsis txhob nquag disassembly, txuag lub sijhawm thiab ua haujlwm zoo.

Lub taub hau sib tov siv L hom tsis siv neeg ntxuav nws tus kheej lub taub hau, koob hom nozzle adjustable, V hom dav hlau orifice, High-pressure collisional mixing txoj cai kom nws muaj txiaj ntsig zoo.

Hluav taws xob tswj system txais cov txiv neej-lub computer interface, teem lub sij hawm txhaj tshuaj, kuaj lub sij hawm thiab siab lub sij hawm thiab lwm yam.

Chiller, Siv los muab cov dej txias rau chav txias, lub tub yees muaj peev xwm 38700Kcal / h ; (kev xaiv)

| Tsis muaj. | Yam khoom | Technical parameter |

| 1 | Ua npuas ncauj thov | Kho kom zoo nkauj yas Moldings |

| 2 | Raw khoom viscosity (22 ℃) | POLY ~2500MPasISO ~1000MPas |

| 3 | Txhaj tshuaj | 10-20Mpa (kho tau) |

| 4 | Cov zis (sib piv 1: 1) | 160-800g / s |

| 5 | Mixing ratio ntau | 1: 5 ~ 5: 1 (kho tau) |

| 6 | Lub sijhawm txhaj tshuaj | 0.5 ~ 99.99S (yog rau 0.01S) |

| 7 | Khoom siv kub tswj yuam kev | ± 2 ℃ |

| 8 | Rov ua qhov tseeb txhaj tshuaj | ± 1% |

| 9 | Muab lub taub hau | Plaub lub tsev roj, ob lub tog raj kheej roj |

| 10 | Hydraulic system | Cov zis: 10L / minSystem siab 10 ~ 20MPa |

| 11 | Tank ntim | 250 L |

| 12 | Input zog | Peb-theem tsib-xaim 380V |

1. Ua los ntawm cov khoom siv polyurethane: ua los ntawm cov pwm pwm thiab txawv ntawm cov ncej ntoo.

2. Muaj cov yam ntxwv ntawm cov ntoo: tuaj yeem khawb, nailed thiab txiav daim iav thav duab

3. Cov xim sib txawv: xws li nyiaj, kaus ntxhw, dub, walnut, cherry, tshauv, xim av, antique kub los yog lwm yam xim muaj.

4. Muaj ntau yam tshiab tsim nrog rau cov tsoos ornate thav duab thiab niaj hnub style ncej.

5. Customized designs, qhov ntau thiab tsawg thiab pob khoom tau txais.

6. Mounted nrog painting, daim iav rau phab ntsa kho kom zoo nkauj los yog ua raws li daim duab ncej rau tsev neeg cov duab.

7. Kev siv tau ntev thiab ib puag ncig tus phooj ywg: dej-pov thawj, noo noo-pov thawj thiab mildew-pov thawj.

[2020] Polyurethane Foaming Tshuab Rau Rooj tog Imitation Ntoo Daim iav Ncej Faux Pob Zeb