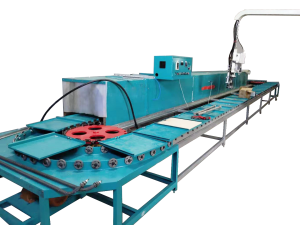

Polyurethane PU & PIR Coldroom Sandwich Vaj Huam Sib Luag Ntau Lawm Kab

Cov khoom siv muaj pes tsawg leeg:

Covkab ntau lawmmuaj

2 teeb ntawm Aluminium ntawv nyiaj ob lub taub hau decoiler tshuab,

4 txheej ntawm huab cua nthuav dav shafts (txhawb aluminium ntawv ci),

1 txheej ntawm Preheating platform,

1 teeb ntawm Kev kub siab foaming tshuab,

1 txheej ntawm movable txhaj tshuaj platform,

1 teeb ntawm Ob chav crawler laminating tshuab,

1 teeb qhov cub cua sov (built-in hom)

1 set ntawm trimming tshuab.

1 teeb tsis siv neeg taug qab thiab txiav tshuab

lub txaj tsis muaj zog

Kev kub siab foaming tshuab:

PU foaming tshuab yog Polyurethane nruam vaj huam sib luagkab ntau lawmcov khoom siv siab, nws yog tsim rau cov nplaim hluav taws kub retardant cov khoom sib xyaw.Lub tshuab no muaj kev txhaj tshuaj siab dua, txawm tias sib tov, kev ua haujlwm ruaj khov, kev ua haujlwm yooj yim, thiab kev ua haujlwm siab ntau lawm, thiab lwm yam.

Ob chav crawler mainframe:

Hauv kev tsim cov khoom siv zoo polyurethane composite board equipments, ob chav crawler mainframe yog cov khoom siv tseem ceeb tshaj plaws, nws yog qhov thib peb kauj ruam tseem ceeb los tsim cov khoom zoo sib xws.Nws feem ntau suav nrog cov hauv qab no: 1) crawler board, 2) kis tau tus mob, thiab 3) skeleton qhia rail system, 4) nce thiab nqis lifting hydraulic xauv system, 5) sab foob module system.

Upper (qis) laminating conveyor:

laminating conveyor yog crawler hom, muaj xws li conveyor thav duab, conveyor saw, saw phaj, thiab qhia rail.Lub tshuab thav duab yog kaw-nyob rau hauv kev tsim kho, uas adopts high-zoo steel vuam ua nrog de-stressing kev kho mob, siab precision qhia rail yog ntsia. ntawm lub tshuab laminating thav duab rau kev txhawb nqa yob bearing ntawm conveyor saw nodes.Txhawm rau txhim kho cov kev taw qhia saum npoo hnav-tiv thaiv kev ua haujlwm ntawm kev taw qhia saum npoo, nws siv GCr15 alloy steel cov khoom, qhov tawv tawv HRC55 ~ 60 °.

Hydraulic lifting thiab tuav ntaus ntawv:

Hydraulic of the elevator thiab cov cuab yeej tuav tau muaj cov hydraulic system, cov xovxwm sab saud kev taw qhia qhov chaw, siv rau kev nce siab, qhov chaw thiab siab tuav ntawm sab sauv conveyor.

| Vaj huam sib luag loj | Dav | 1000 hli |

| Ua npuas ncauj thickness | 20 ~ 60 hli | |

| Min.Txiav ntev | 1000 hli | |

| Linear ceev ntawm ntau lawm | 2 ~ 5m / min | |

| Laminating conveyor ntev | 24m ua | |

| Thaum tshav kub kub max.Temp. | 60 ℃ | |

| Khoom noj tshuab txav ceev | 100mm / s | |

| Khoom noj tshuab kho qhov nrug | 800 hli | |

| Pre-heat qhov cub ntev | 2000 hli | |

| Cov kab ntau lawm (L × Max. dav) | 52m x 8 m | |

| Tag nrho lub zog | cav 120kw | |

Polyurethane phab ntsa hluav taws xob txuag hluav taws xob feem ntau yog siv rau cov phab ntsa sab nrauv ntawm cov tsev steel qauv.Cov vaj huam sib luag muaj kev txuag hluav taws xob zoo, rwb thaiv tsev kub thiab lub suab rwb thaiv tsev, thiab polyurethane tsis txhawb kev sib tsoo, uas yog nyob rau hauv txoj kab nrog kev nyab xeeb hluav taws.Kev sib xyaw ua ke ntawm cov xim sab saud thiab qis dua thiab polyurethane muaj lub zog siab thiab rigidity.Lub vaj huam sib luag hauv qab yog du thiab tiaj tus, thiab cov kab yog qhov tseeb, uas ua rau kev zoo nkauj sab hauv tsev thiab flatness.Yooj yim rau nruab, siv sijhawm luv luv thiab zoo nkauj, nws yog hom tshiab ntawm cov khoom siv hauv tsev.

12 Meter PU Sandwich Vaj Huam Sib Luag Ntau Lawm Kab rau Taug Kev Hauv Chav Txias PUF Vaj Huam Sib Luag Txheej Txheem