Multi-component Cast Elastomer Polyurethane Machine (MDI/TDI) Rau PU Hlau Qhia Rollers

SIB-204hom kub kubelastomer casting tshuabyog tshiab tsim los ntawm peb lub tuam txhab raws li kev kawm thiab absorbing advanced hom kev kawm txawv teb chaws, uas yog dav siv nyob rau hauv zus tau tej cov log, roj hmab npog cov menyuam, sieve, impeller, OA tshuab, skating log, tsis, thiab lwm yam. Lub tshuab no muaj siab rov txhaj tshuaj precision. , txawm tias sib tov, kev ua haujlwm ruaj khov, kev ua haujlwm yooj yim, thiab kev ua haujlwm siab ntau lawm, thiab lwm yam.

1. Rau cov khoom siv sandwich hom thoob, nws muaj kev txuag hluav taws xob zoo

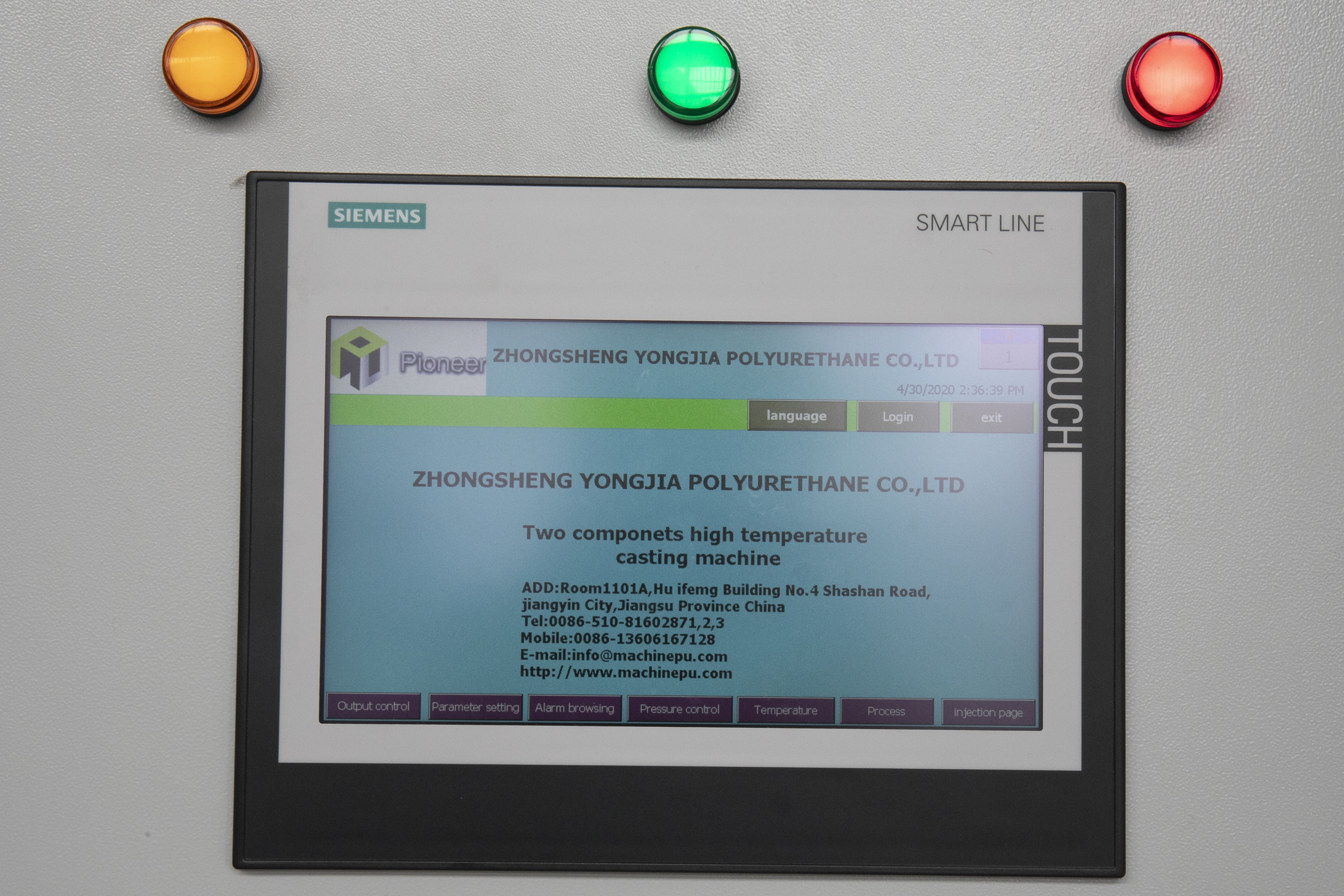

2. Kev txais yuav ntawm PLC kov npo tib neeg-lub computer interface tswj vaj huam sib luag ua rau lub tshuab siv tau yooj yim thiab kev ua haujlwm tau meej meej.

3. Kev kho lub taub hau tswj ncaj qha los ntawm PLC kev ua haujlwm, kev ua haujlwm yooj yim.

4. Kev saws los ntawm hom tshiab sib tov lub taub hau ua rau kev sib xyaw ua ke, nrog cov yam ntxwv ntawm lub suab nrov, ruaj khov thiab ruaj khov.

5. High precision twj tso kua mis ua rau kev ntsuas kom raug.

6. Yooj yim rau kev txij nkawm, kev ua haujlwm thiab kho.

7. Tsawg zog noj.

Ncuav lub taub hau:

Txais kev kub ceev txiav kiv cua V HOM sib tov lub taub hau (tsav hom: V siv), xyuas kom meej txawm tias sib tov nyob rau hauv qhov yuav tsum tau pouring tus nqi thiab sib tov sib piv.Lub cev muaj zog ceev tau nce los ntawm lub log synchronous ceev, ua rau lub taub hau sib hloov nrog kev kub ceev hauv kev sib xyaw cov kab noj hniav.A, B tov yog hloov mus rau lub xeev casting los ntawm lawv cov kev hloov pauv valve, tuaj rau hauv qhov sib xyaw champer los ntawm orifice.Thaum lub taub hau sib tov yog nyob rau hauv kev kub ceev kev sib hloov, nws yuav tsum tau nruab nrog txhim khu kev qha sealing ntaus ntawv kom tsis txhob pouring cov ntaub ntawv thiab xyuas kom meej qhov zoo ntawm cov kabmob.

Electrical apparatus tswj system:

Tsim los ntawm kev hloov hluav taws xob, hloov pauv huab cua, AC contactor thiab tag nrho lub zog, cua sov tswj cov khoom hluav taws xob xws li cua sov thiab lwm yam.Ua kom tiav cov cuab yeej ua haujlwm ua ke nrog PLC (lub sijhawm nchuav thiab tsis siv neeg tu), txhawm rau ua kom nws ua haujlwm zoo.PLC nruab nrog lub tswb ntsuas kub siab los tiv thaiv metering twj thiab cov khoom siv hauv cov khoom siv los ntawm kev puas tsuaj.Tsis tas li ntawd nrog rau qhov kub thiab txias qis rau cov ntaub ntawv pov thawj 'kev ua haujlwm ib txwm nyob hauv qhov kub thiab txias.Qhov ntsuas kub yuam kev ntawm ± 2 ℃.

| 序 号 Tsis muaj. | 项目 Yam khoom | 技术 参 数 Technical Parameter |

| 1 | 注射压力 Txhaj Tshuaj | 0.1-0.6 Mpa |

| 2 | 注射流量 Txhaj tshuaj flow rate | 50-130g / s 3-8Kg / min |

| 3 | 混合比范围 Mixing ratio ntau | 100:6-18(kho tau) |

| 4 | 注射时间 Lub sijhawm txhaj tshuaj | 0.5~99,99 s(精确到0,01s ua) 0.5~99.99S (yog rau 0.01S) |

| 5 | 料温控制误差 Kev tswj qhov kub thiab txias | ± 2 ℃ |

| 6 | 重复注射精度 Rov txhaj tshuaj precision | ± 1% |

| 7 | 混合头sib xyaw taub hau | 约5000转/分钟 ,强制动态混合 Nyob ib ncig ntawm 5000 rpm(4600 ~ 6200rpm, kho tau), yuam dynamic mix |

| 8 | 料罐 积Tank ntim | 220L / 30L |

| Qhov siab tshaj plaws ua haujlwm kub | 70-110 : kuv℃ | |

| B siab tshaj plaws ua haujlwm kub | 110-130 Nws℃ | |

| 9 | 清洗罐 Ntxuav lub tank | 20L 304 # stainless hlau |

| 10 | 计量泵Metering twj tso kua mis | JR50/JR50/JR9 |

| A1 A2Metering twj tso kua mishloov chaw | 50 CC / r | |

| B Metering twj tso kua mishloov chaw | 6 CC/r | |

| A1-A2-B-C1-C2 PUMPS MAXIMUM SPEED | 150 rpm | |

| A1 A2 agitator ceev | 23 rpm | |

| 11 | 压缩空气需要量 compressed cua xav tau | 干燥、无油 qhuav, tsis muaj roj P:0.6-0.8MPa Q:600L / min(Cov neeg siv khoom) |

| 12 | 真空需要量 Vacuum xav tau | P:6 x10-2Pa(6 BAR) 抽气速率ceev ntawm tso pa tawm:15L / S |

| 13 | 温控系统 Kub tswj qhov system | 加热:18~24 kWm Cua sov: 18~24 kWm |

| 14 | 输入电源 Input zog | 三相五线peb kab lus tsib kab lus,380V 50Hz |

| 15 | 加热功率 Cua sov zog | TANKLub hwj chim: 4.6KW TANKPEB: 7.2 KW

|

| 16 | Tag nrho lub zog | 34 kWm |

Cov khoom siv polyurethane yog siv rau hauv ntau yam kev siv thiab kev lag luam.Txawm hais tias feem ntau ntawm peb qhov kev tsom mus rau cov khoom siv loj, pob zeb thiab kev ua liaj ua teb, peb tuaj yeem ua ntau yam ntxiv.

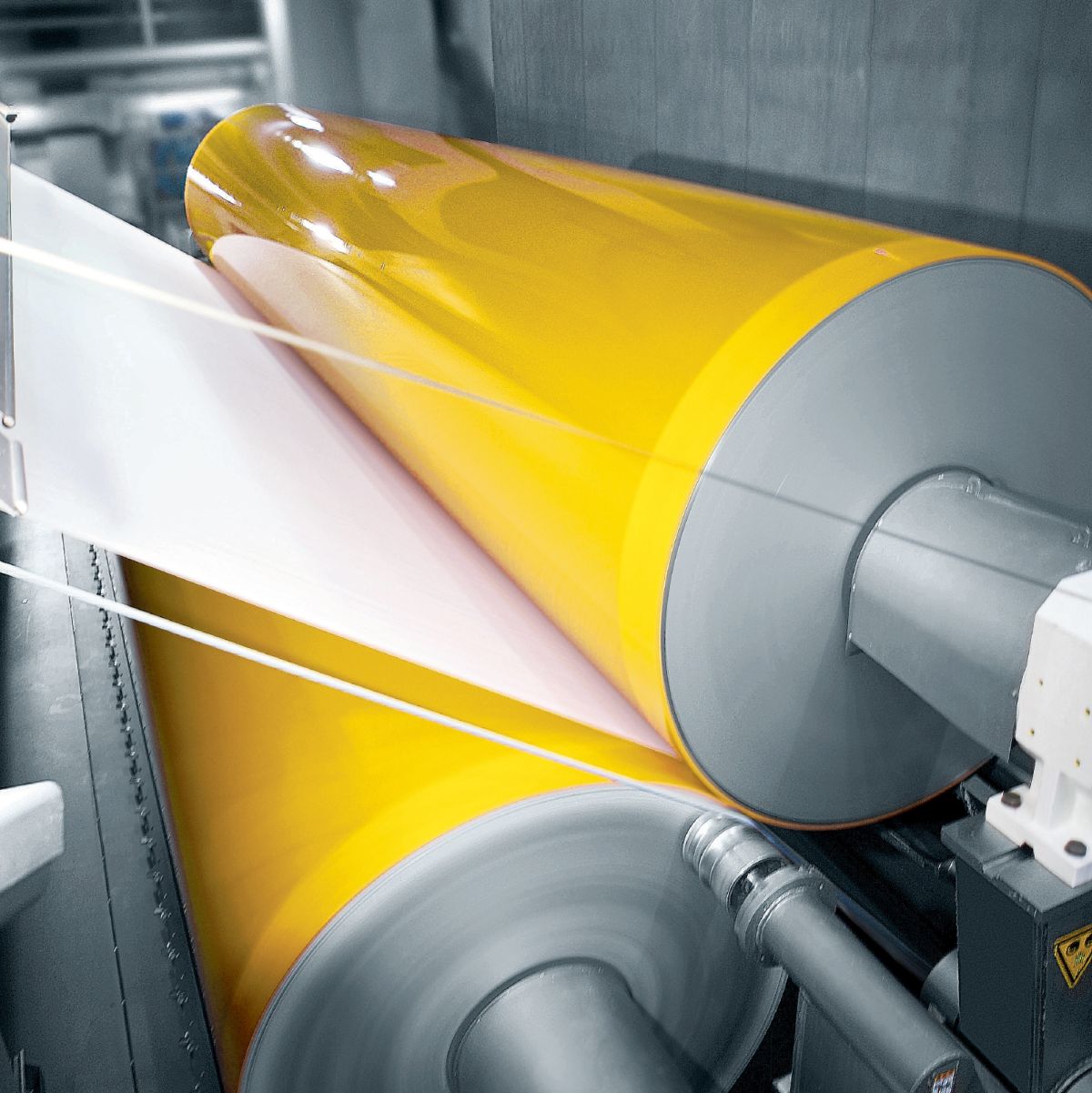

Lwm qhov kev lag luam uas peb tau muaj kev vam meej yog microelectronics thiab photovoltaic industries, qhov twg peb cov hlau txiav cov chais siv hauv kev tsim cov dej silicon rau kev ua silicon chips.Peb cov rollers pab coj cov pob zeb diamond-coated xov hlau los txiav cov khoom siv silicon.

Urethane Wire Guide Rollers Txheej Elastomer Casting Tshuab rau hlau pom cov tshuab hauv cov txheej txheem ntawm pob zeb diamond hlau txiav (mono / multi silicon blocks rau hauv wafers)