JYYJ-3H Polyurethane Spray Foam Tshuab PU Spray Equipment

1. Pneumatic booster ntaus ntawv: Nws muaj qhov zoo ntawm lub teeb yuag, me me, tsis ua haujlwm qis, kev ua haujlwm yooj yim, txav tau yooj yim, thiab kev nyab xeeb.Nws tuaj yeem muab kev ua haujlwm txaus thaum lub sijhawm ua haujlwm.

2. Advanced ventilation system: du ventilation hom, uas tuaj yeem ua kom ruaj khov ntawm cov khoom siv thaum lub sijhawm ua haujlwm.

3. Cov khoom siv raw khoom lim dej: ntau yam khoom siv raw khoom lim tuaj yeem txo qhov teeb meem ntawm cov tshuaj tsuag clogging thiab xyuas kom zoo siv.

4. Kev ruaj ntseg system: Ntau qhov kev tiv thaiv tawm tuaj yeem tiv thaiv kev nyab xeeb ntawm cov neeg ua haujlwm.Nruab nrog lub tshuab hloov hluav taws xob, nws tuaj yeem teb sai sai rau cov xwm txheej ceev.

5. Kev ceev faj thaum siv cov khoom siv: cov ntaub thaiv npog ntsej muag, tsom iav tsom iav, tshuaj tiv thaiv khaub ncaws, hnab looj tes tiv thaiv, khau tiv thaiv

Cua siab regulator:kho highs thiab lows ntawm input cua siab

Barometer:displaying input cua siab

Roj-dej separator:muab cov roj lubricating rau lub tog raj kheej

Air-dej separator:lim cua thiab dej hauv lub tog raj kheej

Lub teeb lub zog:qhia tias muaj voltage input, teeb rau, fais fab rau;teeb tawm, fais fab tuag

Voltmeter:displaying voltage input

Temperature Control Table:Kev teeb tsa thiab tso saib qhov ntsuas kub ntawm lub sijhawm

Thermostat hloov:Tswj-thiab-tawm ntawm cov cua sov system.Thaum nws nyob rau, qhov ntsuas kub ntawm qhov system yuav txiav tawm lub hwj chim txiav tom qab qhov kub nce mus txog qhov chaw, lub teeb yuav raug kaw thaum lub sijhawm;Thaum qhov kub thiab txias yog qis dua qhov chaw, nws yuav qhib qhov cua sov tuaj yeem, lub teeb nyob rau lub sijhawm;Yog tias qhov cua sov tsis xav tau lawm, koj tuaj yeem kaw qhov hloov pauv, lub teeb yuav raug kaw thaum lub sijhawm no.

Pib / Reset hloov pauv:Thaum pib lub tshuab, hloov lub pob rau Start.Thaum ua haujlwm tiav, hloov nws mus rau qhov kev taw qhia rov pib dua.

Hydraulic siab ntsuas:Tso tawm qhov tso zis siab ntawm Iso thiab cov khoom siv polyol thaum lub tshuab ua haujlwm

Hloov pauv xwm ceev:Txiav tawm hluav taws xob sai sai thaum muaj xwm txheej ceev

Raw khoom qhov hluav taws xob:Qhov hluav taws xob ntawm Iso thiab polyol cov ntaub ntawv thiab txuas nrog Iso thiab polyol cov kav dej

Lub zog loj:Fais fab hloov mus qhib thiab tawm ntawm cov khoom siv

Iso / polyol cov ntaub ntawv lim:filtering impurities ntawm Iso thiab polyol khoom nyob rau hauv cov khoom

Lub raj cua sov:cua sov Iso thiab polyol cov ntaub ntawv thiab yog tswj los ntawm Iso / polyol khoom temp.

Cua qhov chaw input: txuas nrog cua compressor

Swb hloov: Tswj input thiab on-and-off ntawm huab cua qhov chaw

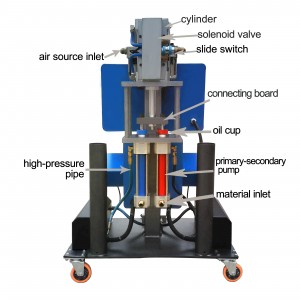

Lub tog raj kheej:Booster Pump muaj zog qhov chaw

Lub zog nkag: AC220V 60hz ua

Primary-Secondary Pumping System:Booster twj tso kua mis rau cov khoom A, B;

Raw khoom inlet: Txuas mus rau lub qhov hluav taws xob pub mis

Solenoid valve (electromagnetic valve): Tswj reciprocating motions ntawm lub tog raj kheej

| Lub zog | ib theem 380V 50HZ |

| Lub zog cua sov | 9.5 kWv |

| Tsav hom: | pneumatic |

| Cua qhov chaw | 0.5 ~ 0.8 MPa ≥0.9m³ / min |

| Cov zis nyoos | 2-10 kg / min |

| Maximum tso zis siab | 25 Mpa ua |

| AB material output ratio | 1: 1 |

Rwb thaiv tsev txau: Rwb thaiv tsev tshuaj tsuag rau sab hauv phab ntsa, ru tsev, txias cia, cabins, carriages, tank, carriages, tsheb tub yees, thiab lwm yam.;

Casting: hnub ci dej rhaub, thermal rwb thaiv tsev dej tank, cabins, thermal rwb thaiv tsev vaj huam sib luag, kev ruaj ntseg qhov rooj, tub yees, pipelines, khoom ntim, kev tsim kho, pwm filling, phab ntsa suab rwb thaiv tsev, thiab lwm yam .;