Gel Coating Machine Gel Pad Making Machine

1. Advanced Technology

Our Gel Pad Production Machines employ state-of-the-art technology, integrating automation, intelligence, and precision control. Whether for small-scale production or large-scale batch manufacturing, we offer solutions tailored to your specific needs.

2. Production Efficiency

Designed for maximum efficiency, our machines ensure you can quickly meet market demands through high-speed, high-precision production processes. The increased level of automation not only boosts production efficiency but also lowers operational costs.

3. Flexibility and Variety

Our Gel Pad Production Machines exhibit outstanding flexibility, accommodating the production of gel pads in various sizes, shapes, and materials. From standard designs to personalized customization, we provide flexible and diverse production solutions.

4. Quality Control

Quality is at the core of our concerns. Through advanced inspection and control systems, we ensure that each gel pad meets the highest quality standards. We pay attention to details, committed to delivering consistently excellent quality to our customers.

5. Intelligent Operation

Equipped with user-friendly interfaces, our Gel Pad Production Machines feature intelligent operation. Visual control systems and real-time monitoring functions make the operation intuitive and straightforward.

6. Environmental Sustainability

We prioritize environmental considerations in our machine design, aiming for energy efficiency and sustainability. Efficient energy utilization and low waste rates contribute to making your production more environmentally friendly.

7. After-Sales Service

Beyond providing high-quality Gel Pad Production Machines, we offer comprehensive after-sales services. Our professional team provides training, maintenance, and technical support to ensure you maximize the utilization of our production machines.

|

Stainless steel machine frame, capacity

|

1-30g/s

|

|

Ratio adjustment

|

machine gearing ratio/electric gearing ratio

|

|

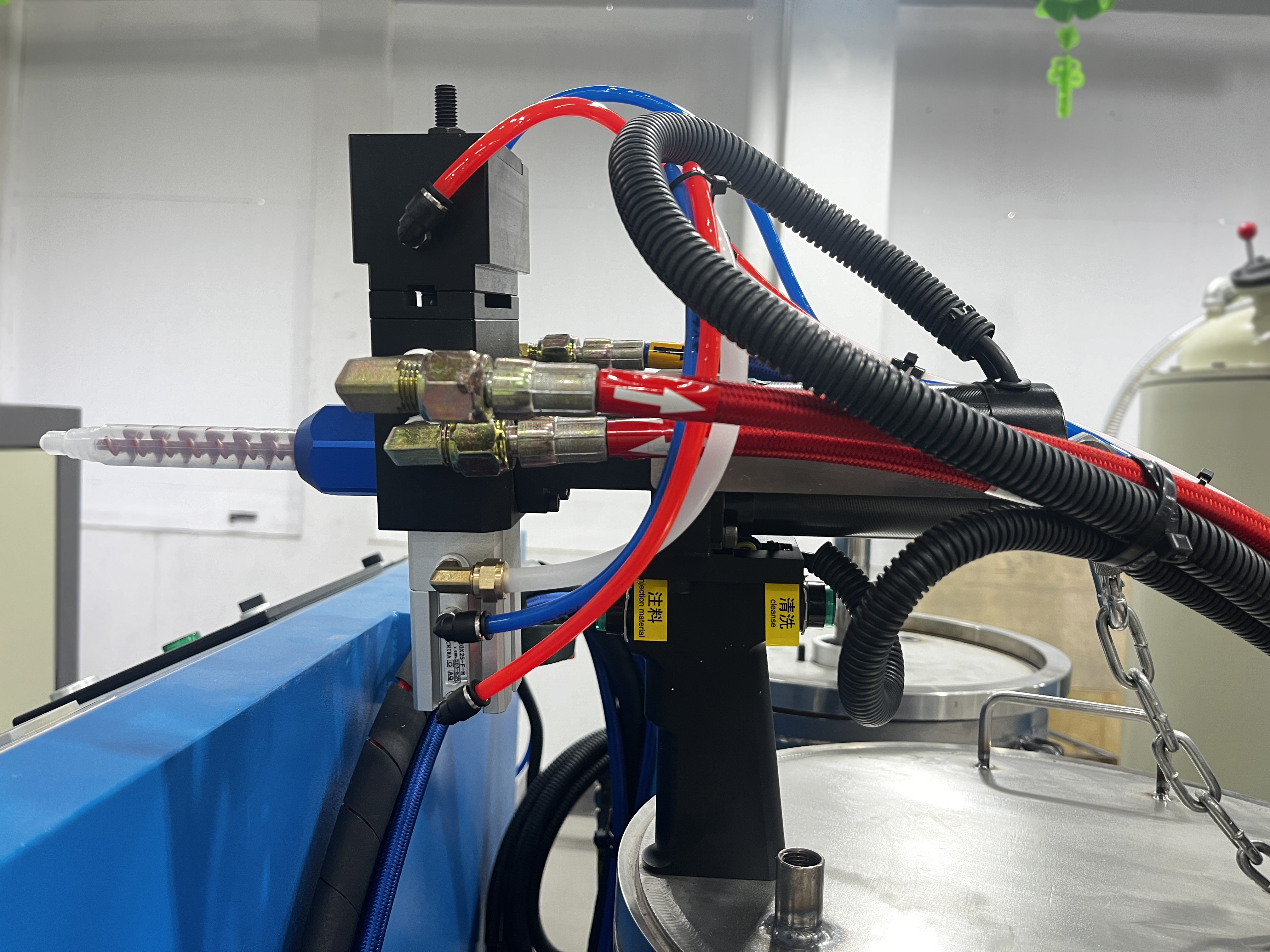

Mixing type

|

static mixing

|

|

Machine size

|

1200mm*800mm*1400mm

|

|

Power

|

2000w

|

|

Working air pressure

|

4-7kg

|

|

Working voltage

|

220V, 50HZ

|