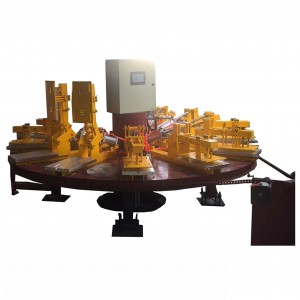

Fork Wheel Making Machine Polyurathane Elastomer Casting Machine

1) High temperature resistant low speed high precision metering pump,accurate measurement,random error within +0.5%;

2) Material output adjusted by frequency converter with frequency motor,high pressure and precision,sample and rapid ratio control;

3) New type mechanical seal structure avoids reflux problem;

4) High-efficiency vacuum device with special mixing head ensure product no bubbles;

5) Muti-point temp control system ensures stable temperature,random error <±2℃;

6) High performance mixing device,adjustable pressure

Buffer tank Buffer tank used for vacuum pump to filtering and pump Vacuum pressure accumulator. Vacuum pump draws air in the tank through the buffer tank, lead the raw material air reduction and achieve less bubble in the final products.  Pour head Adopting high speed cutting propeller V TYPE mixing head (drive mode: V belt), ensure even mixing within the required pouring amount and mixing ratio range. Motor speed increased through a synchronous wheel speed, making the mixing head rotate with high speed in mixing cavity. A, B solution are switched to casting state by their respective conversion valve, come into the mixing champer through orifice. When the mixing head was at high speed rotation, it should be equipped with reliable sealing device to avoid pouring material and ensure the normal operation of the bearing.

Pour head Adopting high speed cutting propeller V TYPE mixing head (drive mode: V belt), ensure even mixing within the required pouring amount and mixing ratio range. Motor speed increased through a synchronous wheel speed, making the mixing head rotate with high speed in mixing cavity. A, B solution are switched to casting state by their respective conversion valve, come into the mixing champer through orifice. When the mixing head was at high speed rotation, it should be equipped with reliable sealing device to avoid pouring material and ensure the normal operation of the bearing.

|

Item |

Technical Parameter |

|

Injection Pressure |

0.01-0.1Mpa |

|

Injection flow rate |

85-250g/s 5-15Kg/min |

|

Mixing ratio range |

100:10~20(adjustable) |

|

Injection time |

0.5~99.99S (correct to 0.01S) |

| Temperature control error |

±2℃ |

|

Repeated injection precision |

±1% |

|

Mixing head |

Around 6000rpm, forced dynamic mixing |

|

Tank volume |

250L /250L/35L |

|

Metering pump |

JR70/ JR70/JR9 |

|

Compressed air requirement |

Dry, oil free P:0.6-0.8MPa Q:600L/min(Customer-owned) |

|

Vacuum requirement |

P:6X10-2Pa Speed of exhaust:15L/S |

|

Temperature control system |

Heating: 31KW |

|

Input power |

Three-phrase five-wire,380V 50HZ |

|

Rated power |

45KW |

|

Swing arm |

Fixed arm, 1 meter |

|

Volume |

About 2000*2400*2700mm |

|

Color (selectable) |

Deep blue |

|

Weight |

2500Kg |