Introduces the advanced international production technology and high quality raw materials for the ceramic products.

Recommended Products

-

21Bar Screw Diesel Air Compressor Air Compresso...

Feature High Efficiency and Energy Savings: Our air compressors employ advanced technology to maximize energy efficiency. The efficient compression system reduces energy consumption, contributing to lower energy costs. Reliability and Durability: Built with robust materials and impeccable manufacturing processes, our air compressors ensure stable operation and an extended lifespan. This translates to reduced maintenance and dependable performance. Versatile Applications: Our air compressors ...

-

15HP 11KW IP23 380V50HZ Fixed speed PM VSD Scre...

Feature Compressed Air Supply: Air compressors intake air from the atmosphere and, after compressing it, push it into an air tank or supply pipeline, providing high-pressure, high-density air. Industrial Applications: Air compressors are widely used in manufacturing, construction, chemical, mining, and other industries. They are used to operate pneumatic equipment, for tasks such as spraying, cleaning, packaging, mixing, and various industrial processes. Energy Efficiency and Environmental F...

-

Fully Automatic Hot Melt Adhesive Dispensing Ma...

Feature 1. High-Speed Efficiency: The Hot Melt Glue Dispensing Machine is renowned for its high-speed adhesive application and rapid drying, significantly enhancing production efficiency. 2. Precise Gluing Control: These machines achieve high-precision gluing, ensuring every application is accurate and uniform, eliminating the need for secondary processing. 3. Versatile Applications: Hot Melt Glue Dispensing Machines find applications in various industrial processes, including packaging, cart...

-

Fully Automatic Syringe Dispensing Machine Ppro...

Feature High Precision: Syringe dispensing machines can achieve extremely high liquid dispensing accuracy, ensuring precise and error-free adhesive application every time. Automation: These machines are often equipped with computer control systems, enabling automated liquid dispensing processes that enhance production efficiency. Versatility: Syringe dispensing machines can accommodate various liquid materials, including adhesives, colloids, silicones, and more, making them versatile in appl...

-

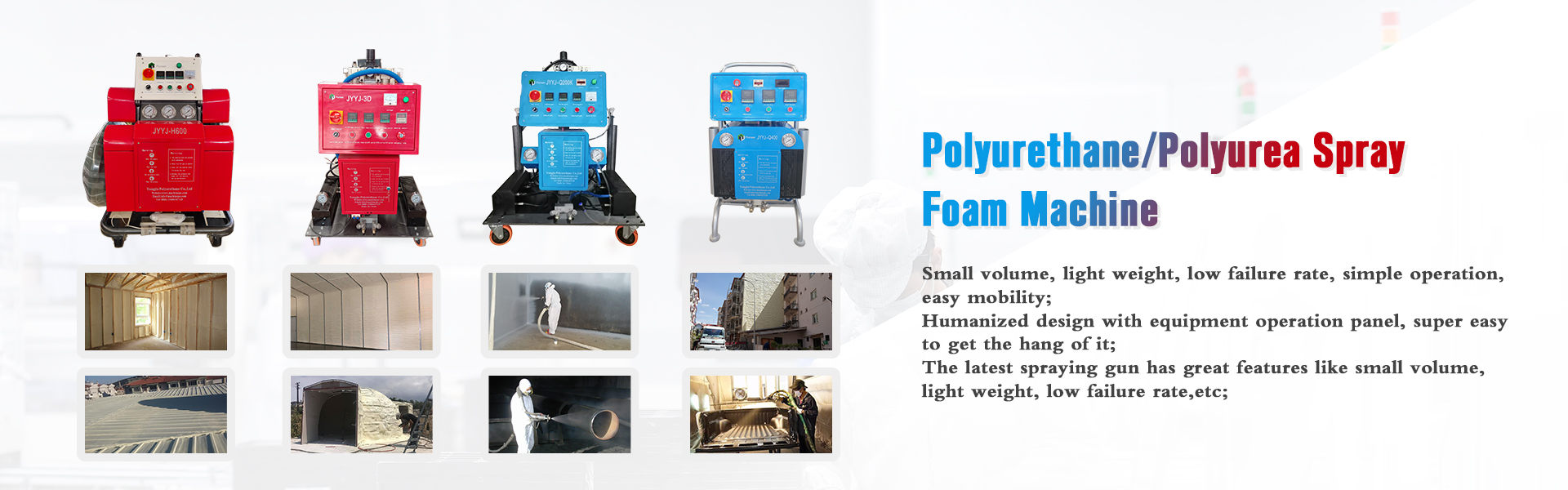

JYYJ-3D Polyurethane Insulation Foam Spray Mach...

Feature 1.Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum; 2. Lifting pump adopts big change ratio method, the winter also can easily feed raw materials high viscosity 3. Feed rate can be adjusted,have time-set,quantity-set features, suitable for batch casting, improve production efficiency; 4. With small volume, light weight, low failure rate, easy operation and other great features; 5. Secondary pressurized device to ensure fixed material...

-

Cyclopentane Series High Pressure Foaming Machine

The black and white materials are mixed with the premix of cyclopentane through the injection gun head of the high-pressure foaming machine and injected into the interlayer between the outer shell and the inner shell of the box or door. Under certain temperature conditions, the polyisocyanate (isocyanate (-NCO) in the polyisocyanate) and the combined polyether (hydroxyl (-OH)) in the chemical reaction under the action of the catalyst to generate polyurethane, while releasing a lot of heat. At...

-

High Pressure Polyurethane Foam Injection Machine

Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine. This polyurethane foaming machine uses two raw materials, polyol and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry. Produc...

-

Low Pressure PU Foaming Machine

PU low pressure foaming machine is newly developed by Yongjia company based on learning and absorbing advanced techniques abroad, which is widely employed in the production of automotive parts, automotive interior, toys, memory pillow and other kinds of flexible foams like integral skin, high resilience and slow rebound , etc. This machine has high repeat injection precision, even mixing, stable performance, easy operation, and high production efficiency, etc. Features 1.For sandwich type ma...

-

Three Components Polyurethane Injection Machine

The three-component low-pressure foaming machine is designed for simultaneous production of double-density products with different densities. Color paste can be added at the same time, and products with different colors and different densities can be switched instantly. Features 1.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving; 2.Adding material sample test system, which can b...

-

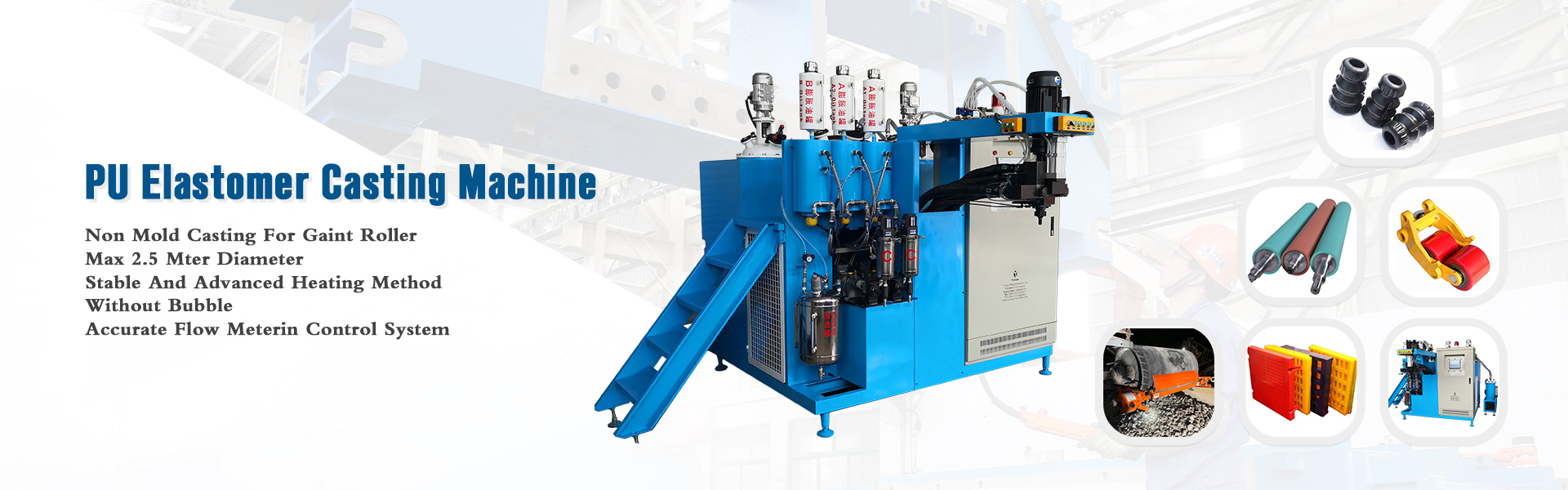

PU Elastomer Casting Machine

High temperature elastomer casting machine is newly developed by Yongjia company based on learning and absorbing advanced techniques abroad, which is widely employed in the production of wheel, rubber covered roller, sieve, impeller, OA machine, skating wheel, buffer, etc. This machine has high repeat injection precision, even mixing, stable performance, easy operation, and high production efficiency, etc. Features 1.High temperature resistant low speed high precision metering pump, accurate...

-

Car Air Filter Gasket Pad Casting Machine

Air filter is one of the necessary internal combustion machinery such as a /, with the rapid development of automobile industry, with microporous elastomer polyether type low density as air filter, end cover is widely used in automobile industry.The company developed filter gasket pouring machine has simple operation, easy maintenance, high degree of automation, stable performance. Features 1. High precision metering pump, metering precision, precision error is not more than plus or minus 0.5...

-

PU Anti-fatigue Mat Molds

Anti-fatigue mats are beneficial for back thigh and lower leg or foot,which offer you unique feeling from your head to your toe. Anti fatigue mat is a natural shock absorber, and it can rebound quickly to the smallest weight shift, encourage blood flow to feet, legs, and lower back. The anti fatigue mat is engineered to the optimal degree of softness to minimize the harmful, painful consequences of standing for extended periods as well as to reduce the stress and strain of standing. Anti-Fati...

Trust us, choose us

About Us

Brief description:

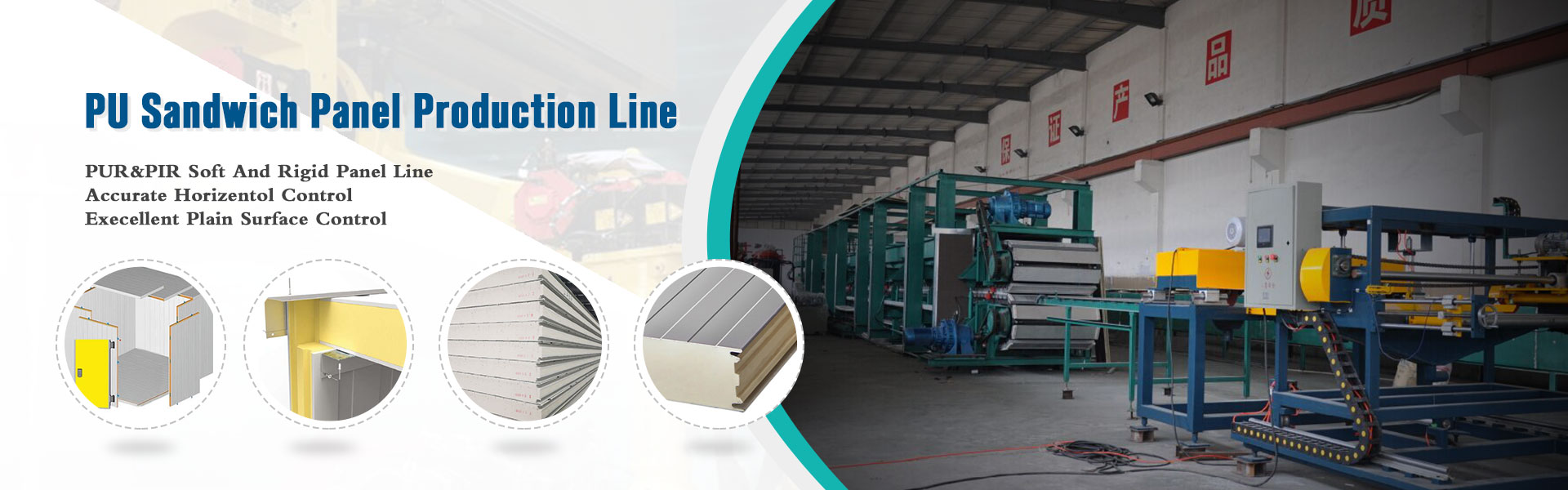

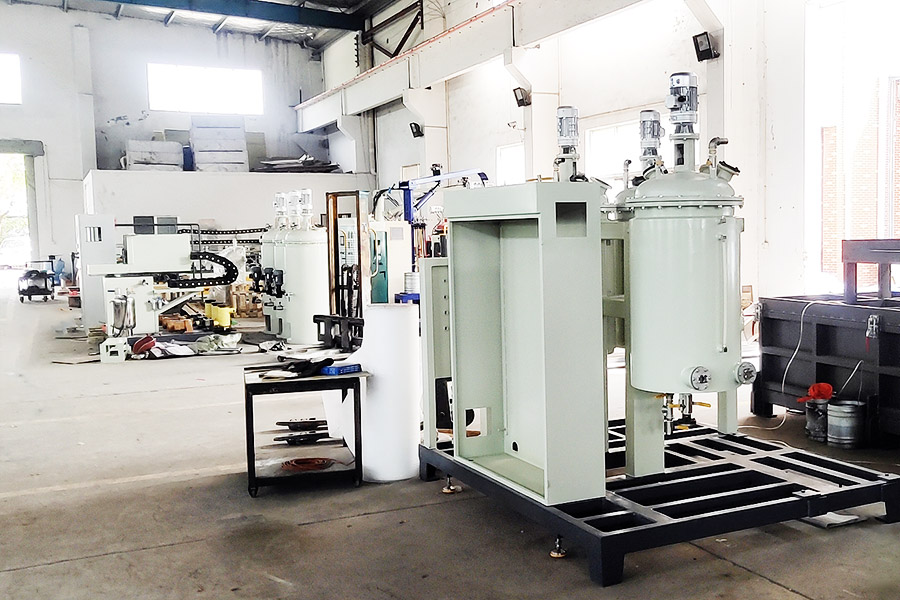

Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development and production. Since founded in 2013, Yongjia has been the Chinese forefront polyurethane technology company with more than 10,000 square meters of construction area.

At present our company’s products range covers: high pressure pouring machine, low pressure foaming machine, PU/ Polyurea spraying foam machine, PU elastomer casting machine.We can also make customized production line according to clients’ different requirements.