Automatic PU Foam Injection Molding Machine for Memory Foam Pillows

The equipment consists of a polyurethane foaming machine (low-pressure foaming machine or high-pressure foaming machine) and a production line. Customized production can be carried out according to the nature and requirements of customers’ products.

This production line is used to produce polyurethane PU memory pillows, memory foam, slow rebound/high rebound foam, car seats, bicycle saddles, motorcycle seat cushions, electric bicycle saddles, home cushions, office chairs, sofas, auditorium chairs, etc. Sponge foam products.

Main unit:

Material injection by a precision needle valve, which is taper sealed, never worn, and never clogged; the mixing head produces complete material stirring; precise metering (K series precision metering pump control is exclsively adopted); single button operation for convenient operation; switching to a different density or color at any time; easy to maintain and operate.

Control:

Microcomputer PLC control; TIAN electrical components exclsively imported to achieve the goal for automatic, accurate and reliable control can be imputed with more than 500 working position data; pressure, temperature and rotation rate digital tracking and display and automatic control; abnormity or fault alarm devices. Imported frequency converter (PLC) can control the proportion of 8 different products.

| No. | Item | Technical Parameter |

| 1 | Foam application | Flexible foam |

| 2 | Raw material viscosity(22℃) | POL ~3000CPSISO ~1000MPas |

| 3 | Injection Output | 155.8-623.3g/s |

| 4 | Mixing ratio range | 100:28~50 |

| 5 | Mixing head | 2800-5000rpm, forced dynamic mixing |

| 6 | Tank Volume | 120L |

| 7 | Metering pump | A pump: GPA3-63 Type B Pump: GPA3-25 Type |

| 8 | Compressed air requirement | dry, oil free P:0.6-0.8MPaQ:600NL/min(Customer-owned) |

| 9 | Nitrogen requirement | P:0.05MPaQ:600NL/min(Customer-owned) |

| 10 | Temperature control system | heat:2×3.2kW |

| 11 | Input power | three-phrase five-wire,415V 50HZ |

| 12 | Rated power | about 13KW |

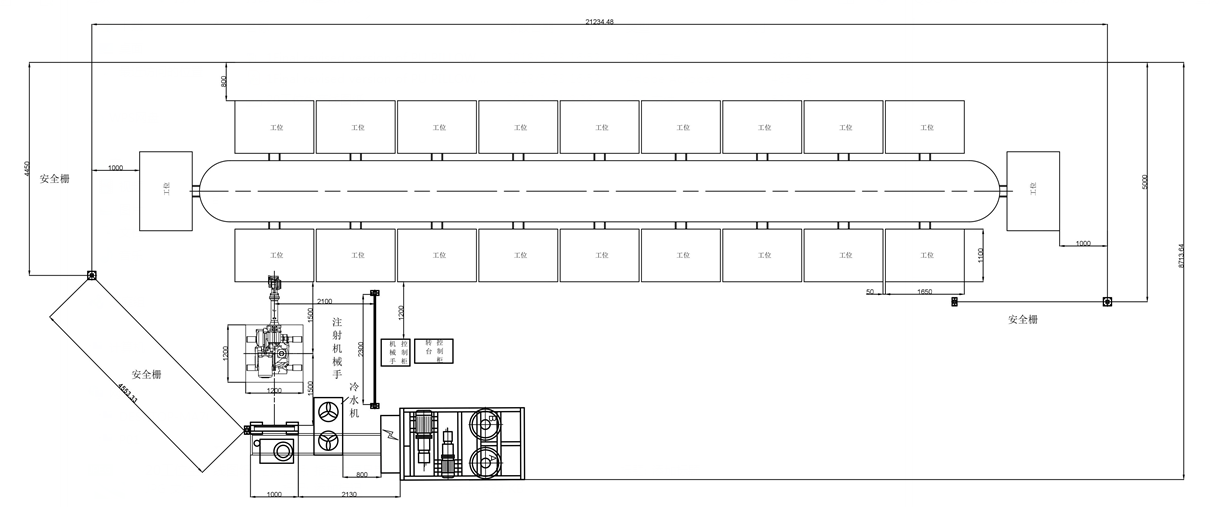

The twenty station foaming line is arranged in a planar ring structure, and the frequency conversion motor is used to drive the whole motion of the wire body through a variable speed turbine box. The speed of the transmission line can be adjusted by frequency conversion, which is convenient to adjust the production rhythm. The power supply adopts the sliding contact line is introduced, the external source of central gas supply, introduced into each frame body through the joint line. In order to facilitate the replacement of mold and maintenance, the temperature control water, cable and compressed air between the various positions of the mold and the connection of the fast plug connection.

It is Safe and reliable with the mold of airbag to open &close.

The general frame is composed of a base, shelves, loading template, rotary pin, rotating connecting plate, pneumatic circuit and control circuit, using PLC control, complete mold, mould closing, core pulling, ventilation and a series of actions, simple circuit, convenient maintenance. The mould frame is provided with a pneumatic interface of a core pulling cylinder and a ventilating needle, and the die with the core pulling cylinder and the ventilating needle can be directly connected with a quick connector.

SPU-R2A63-A40 type low pressure foaming machine is newly developed by Yongjia company based on learning and absorbing advanced techniques abroad, which is widely employed in the production of automotive parts, automotive interior, toys, memory pillow and other kinds of flexible foams like integral skin, high resilience and slow rebound , etc. This machine has high repeat injection precision, even mixing, stable performance, easy operation, and high production efficiency, etc.

PU polyurethane foaming machine can be used in the manufacture of PU pillows.This polyurethane material pillow is soft and comfortable, has the advantages of decompression, slow rebound, good air permeability, etc. It is a high-tech material.The size and shape of the PU pillow can be customized.

Polyurethane Machine For Memory Pillow