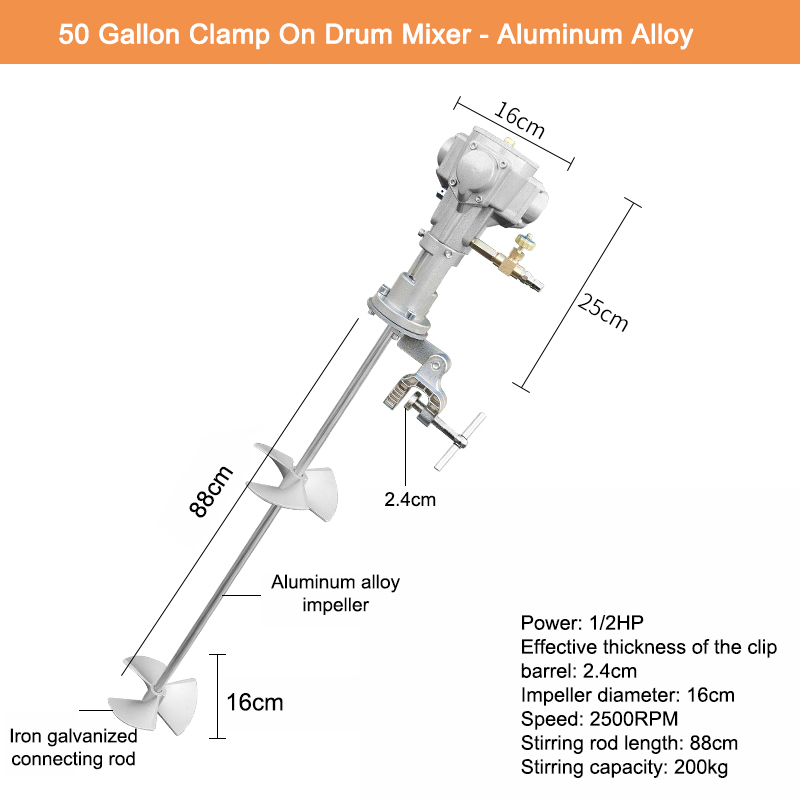

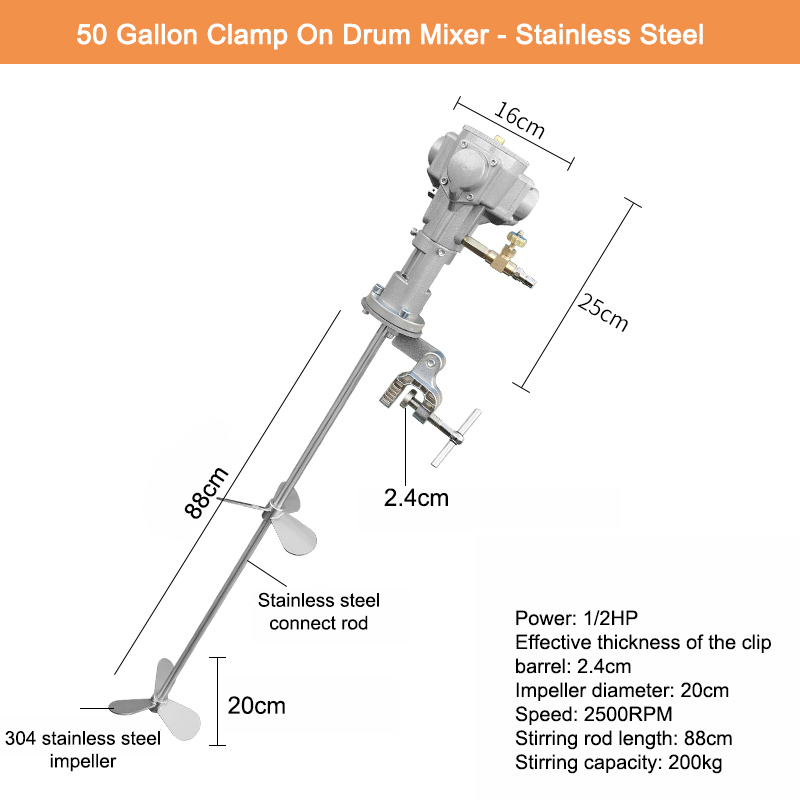

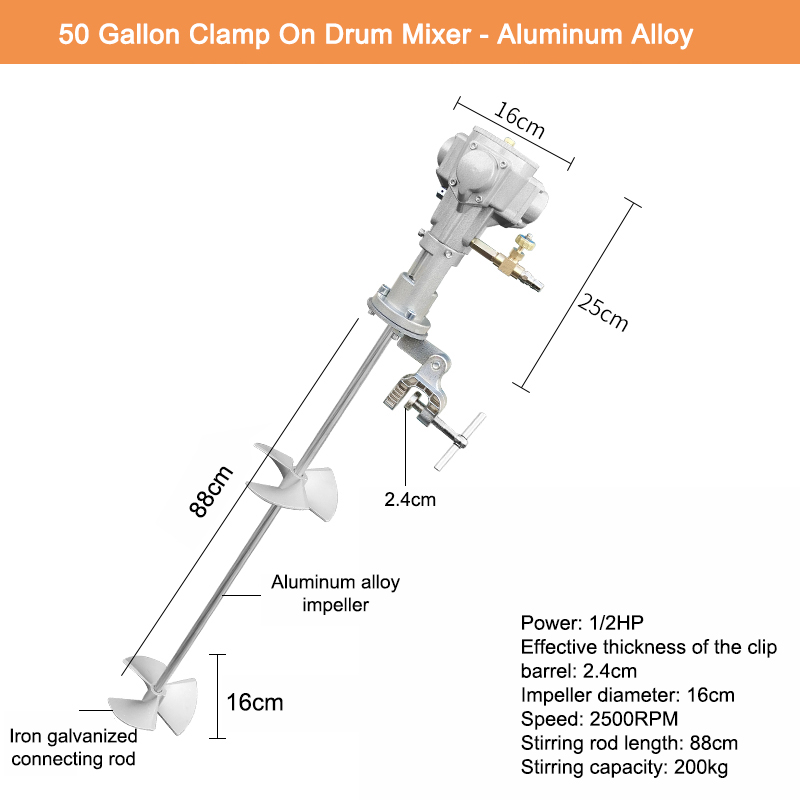

50 Gallon Clamp On Drum Stainless Steel Mixer Aluminum Alloy Mixer

1. It can be fixed on the barrel wall, and the stirring process is stable.

2. It is suitable for stirring various open-type material tanks, and is easy to disassemble and assemble.

3. Double aluminum alloy paddles, large stirring circulation.

4. Use compressed air as power, no sparks, explosion-proof.

5. The speed can be adjusted steplessly, and the speed of the motor is regulated by the pressure of the air supply and the flow valve.

6. There is no danger of overloading. When the pneumatic mixer is overloaded, it will not cause damage to the mixer itself, and the temperature of the fuselage will not rise. It can work continuously for a long time with full load.

7. Easy to operate, easy to maintain and overhaul

8. It is suitable for working in harsh environments such as flammable, explosive, vibrating, and wet.

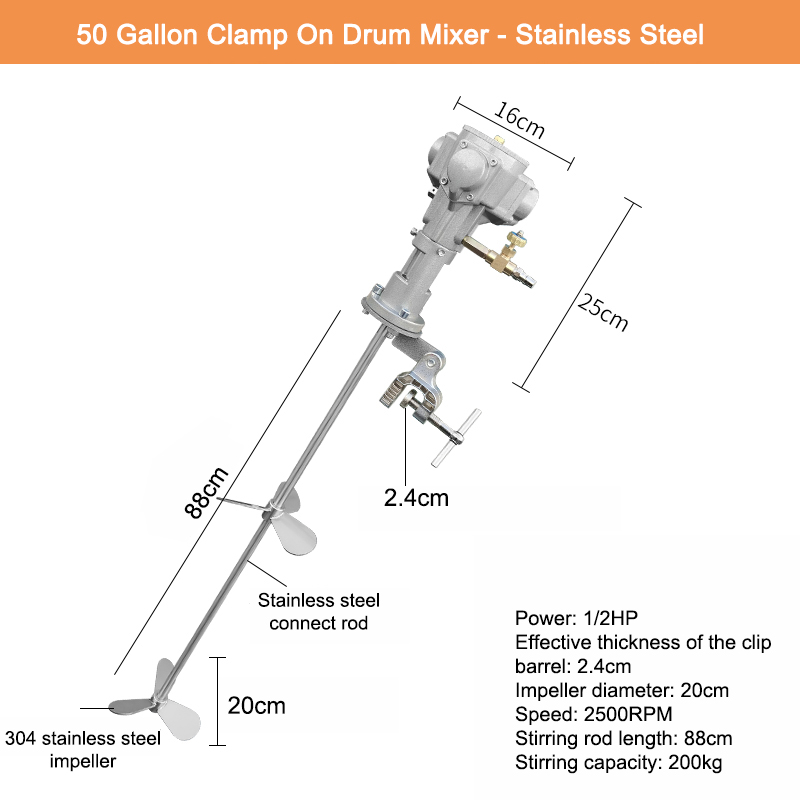

| Power | 1/2HP |

| Effective thickness of the clip barrel | 2.4cm |

| Impeller diameter | 16cm or 20cm |

| Speed | 2500RPM |

| Stirring rod length | 88cm |

| Stirring capacity | 200kg |

Widely used in coatings, paints, solvents, inks, chemicals, food, beverages, medicines, rubber, leather, glue, wood, ceramics, emulsions, greases, oils, lubricating oils, epoxy resins and other open materials with medium and low viscosity liquids bucket mixing